In the world of manufacturing, packaging, and printing, hot stamping machines have revolutionized how businesses add elegance, brand recognition, and value to their products. This versatile technology applies metallic or colored foils to various surfaces, creating eye-catching designs that stand out in competitive markets.

What is a Hot Stamping Machine?

A hot stamping machine is a piece of equipment that uses heat, pressure, and time to transfer metallic or pigmented foils onto a substrate. The process involves pressing a heated die onto the foil, which then adheres to the surface beneath it, leaving a permanent, high-quality mark.

This technique has been around for centuries, evolving from hand-operated tools to sophisticated automated systems that handle high-volume production with precision and consistency.

How Does Hot Stamping Work?

The hot stamping process follows these basic steps:

- Preparation: The substrate material is positioned correctly, and the appropriate foil is loaded onto the machine.

- Heating: The stamping die is heated to the optimal temperature (typically between 100-200°C depending on materials).

- Application: The die presses down onto the foil, which melts slightly and transfers onto the substrate.

- Release: As the die lifts, the foil releases, leaving the desired design on the material.

The entire process happens in milliseconds, allowing for efficient production even at high speeds.

Types of Hot Stamping Machines

Hot stamping machines come in various configurations to suit different applications:

- Manual Machines: Ideal for small businesses or low-volume production, these require operator intervention for each stamping.

- Semi-automatic Machines: Combine manual feeding with automated stamping processes for increased efficiency.

- Fully Automatic Machines: Handle high-volume production with automated feeding, stamping, and unloading.

- Roll-to-roll Machines: Designed for continuous materials like paper or film, perfect for packaging production lines.

- 3D Hot Stamping Machines: Capable of applying foil to curved or irregular surfaces with consistent results.

Materials Suitable for Hot Stamping

One of the key advantages of hot stamping is its versatility across materials:

- Paper and cardboard (common in packaging and stationery)

- Plastics (PVC, ABS, PP, and more)

- Leather (used in luxury goods and apparel)

- Wood (furniture and decorative items)

- Textiles (fashion accessories and branding)

- Metals (for specialized industrial applications)

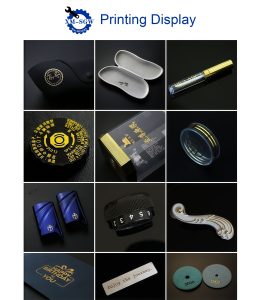

Applications Across Industries

Hot stamping technology finds applications in numerous sectors:

- Packaging: Adding logos, decorative elements, or security features to boxes and containers

- Publishing: Enhancing book covers, magazines, and greeting cards

- Fashion: Branding leather goods, apparel, and accessories

- Electronics: Creating durable labels on devices and components

- Automotive: Interior trim decoration and branding

- Luxury Goods: Adding premium finishes to high-end products

Benefits of Hot Stamping

Businesses choose hot stamping for several compelling reasons:

- Durability: Stamped designs resist wear, water, and UV exposure better than many printing methods

- Premium Appearance: Metallic foils create a luxurious look that enhances perceived value

- Versatility: Works on diverse materials with consistent results

- Eco-friendliness: Requires no inks or solvents, reducing environmental impact

- Security: Special foils can incorporate security features to prevent counterfeiting

Choosing the Right Hot Stamping Machine

Selecting the appropriate machine depends on several factors:

- Production Volume: Determine whether you need a manual machine for small runs or an automated system for mass production

- Substrate Type: Ensure the machine can handle your specific materials

- Design Complexity: Intricate designs may require more precise equipment

- Workspace Constraints: Consider available floor space for installation

- Budget: Balance upfront investment with long-term production needs

Maintenance and Troubleshooting

Proper maintenance ensures optimal performance and longevity:

- Regularly clean dies and heating elements

- Check and replace worn foil guides

- Calibrate temperature settings periodically

- Lubricate moving parts as recommended by the manufacturer

Common issues include uneven stamping (often due to temperature fluctuations), incomplete transfers (usually from insufficient pressure), and foil wrinkling (typically caused by improper tension).

The Future of Hot Stamping Technology

Advancements in hot stamping continue to expand its capabilities, with developments in:

- Digital hot stamping for on-demand customization

- Improved energy efficiency in heating elements

- Integration with Industry 4.0 systems for smart production monitoring

- New foil materials offering enhanced effects and sustainability

Whether you’re a small business looking to add premium touches to your products or a large manufacturer seeking efficient branding solutions, hot stamping machines provide a versatile, cost-effective way to elevate your offerings in today’s competitive marketplace.