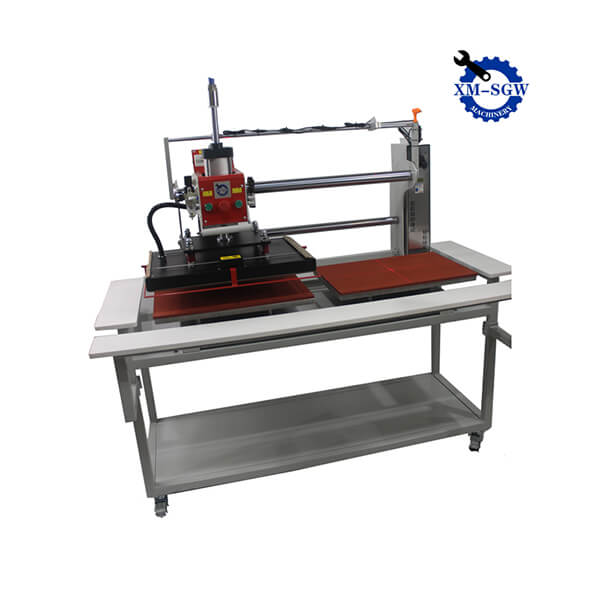

Hot-selling Double-station Laser Positioning 20*20cm Hot Pressing Machine for T-shirt Throw Pillow Bag

- Fast response speed, suitable for welding of fast heat conduction workpiece.

- Powerful learning function, stable output temperature, avoid overshoot.

- Fault diagnosis and alarm function to prevent workpiece damage.

- Heating technology, precise temperature control.

- Diversified working modes to meet different application requirements.

Products Categories

Get A Free Quote

Double-station Hot Pressing Machine for T-shirt Description

Double-station hot press Data Sheet

| Power | 1200W |

| Working voltage | 220V/110V |

| Plate Type | Heat Press Machine |

| Core Components | Digital control |

| Working area | 100mm*100mm 150mm*150mm 200*200mm 200*300mm |

| Driven Type | Pneumatic |

| Dimensions(L*W*H) | 76*60*72cm |

| Weight | 40KG |

| Control | Timer control |

| pad | Heat-resistant silicone pad |

| temperature | Dual temperature control |

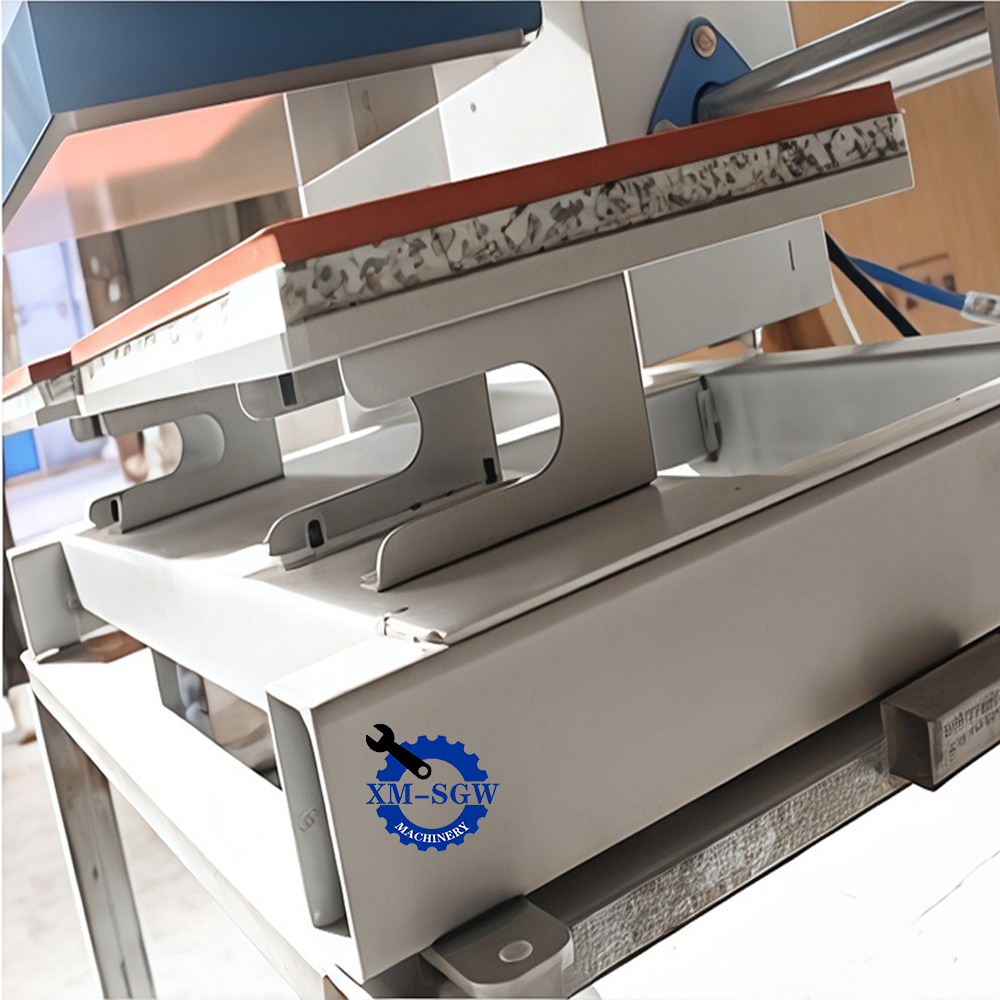

1. Dual-Station Design for Max Productivity

Enables non-stop, alternating operation between two independent workstations—while one station is in the heat- pressing cycle, the other can be loaded/unloaded. This eliminates idle time, boosting overall throughput by up to 50% compared to single-station models, ideal for high-volume production.

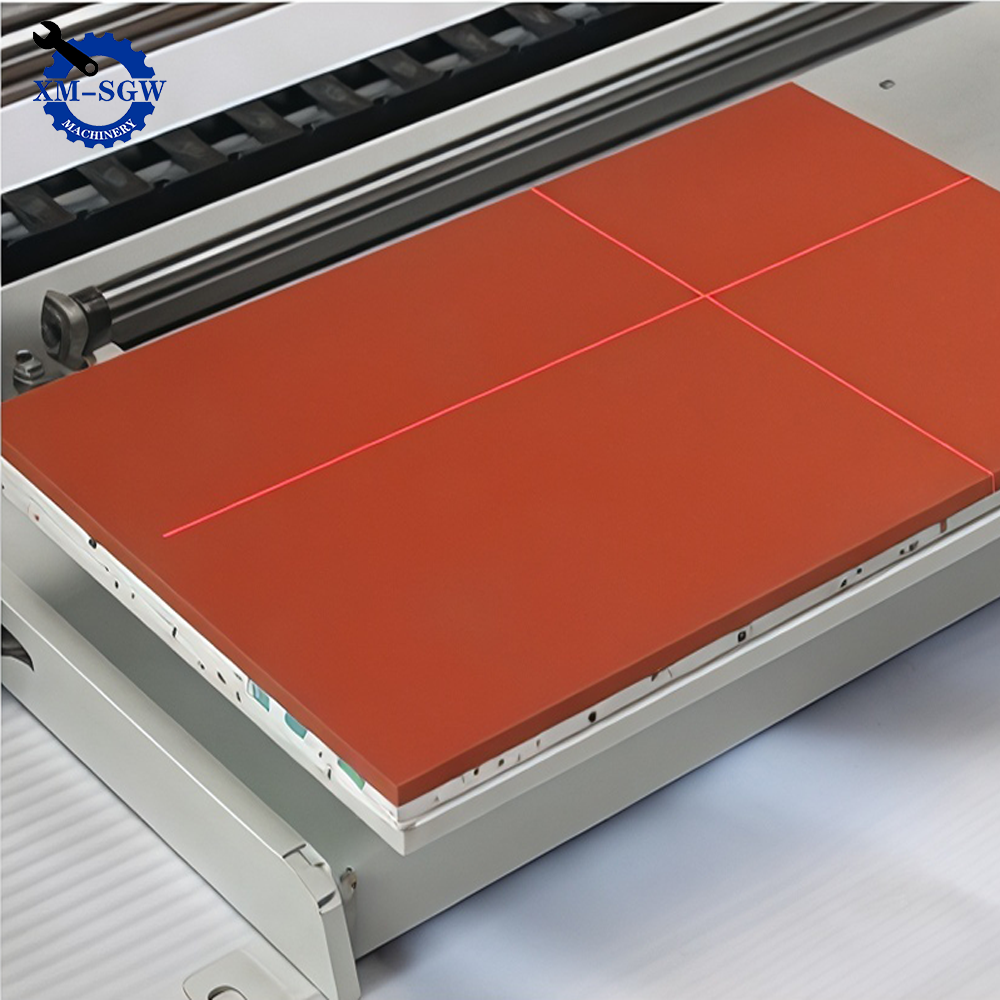

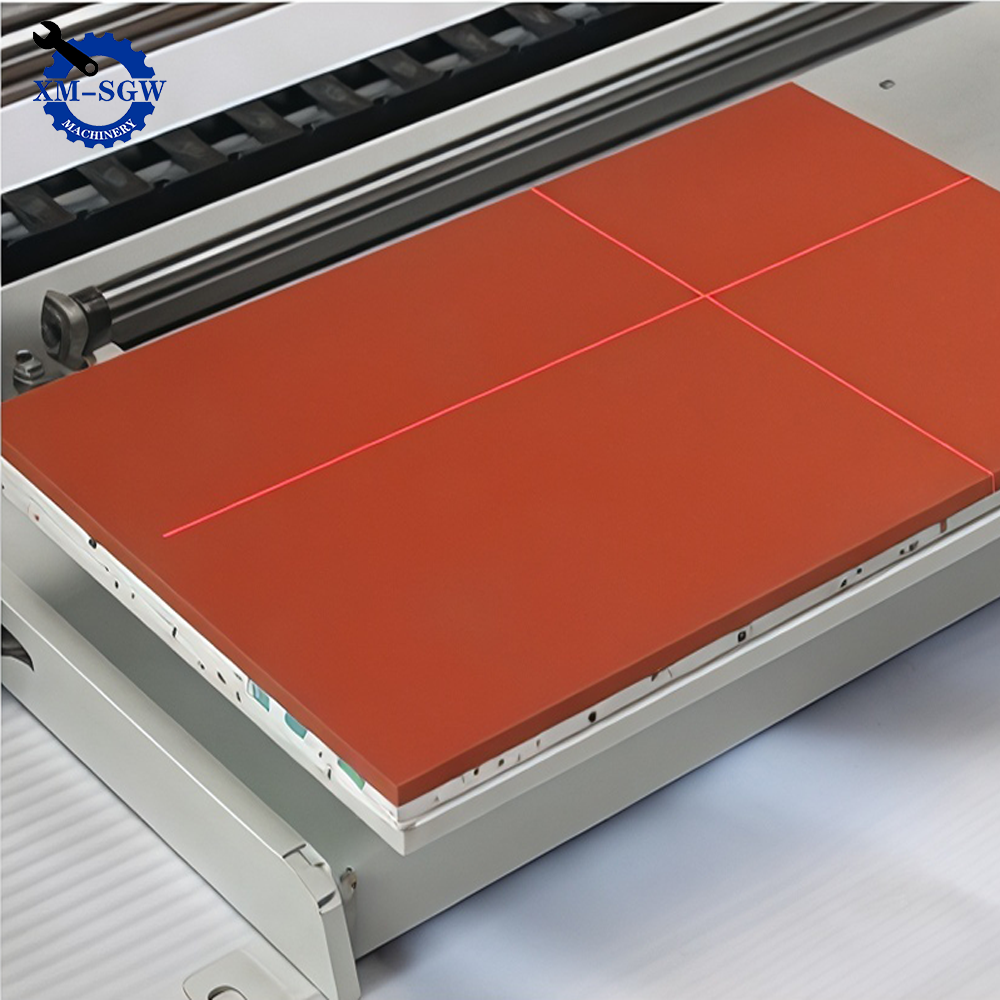

2. High-Precision Laser Positioning System

Integrates a high-accuracy laser alignment module that pinpoints workpieces with positioning error of ≤0.1mm. Ensures consistent placement of materials (e.g., laminates, adhesives, electronic components) across every cycle, minimizing defects and improving product yield.

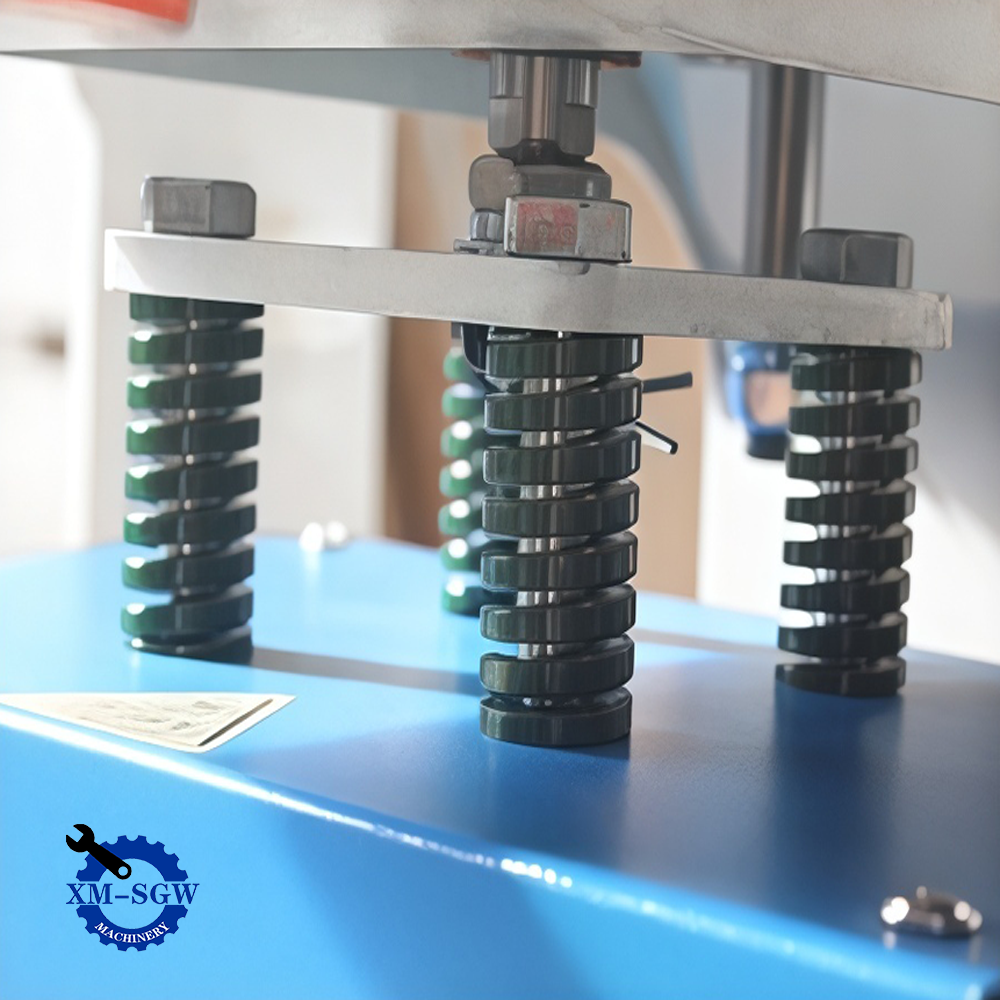

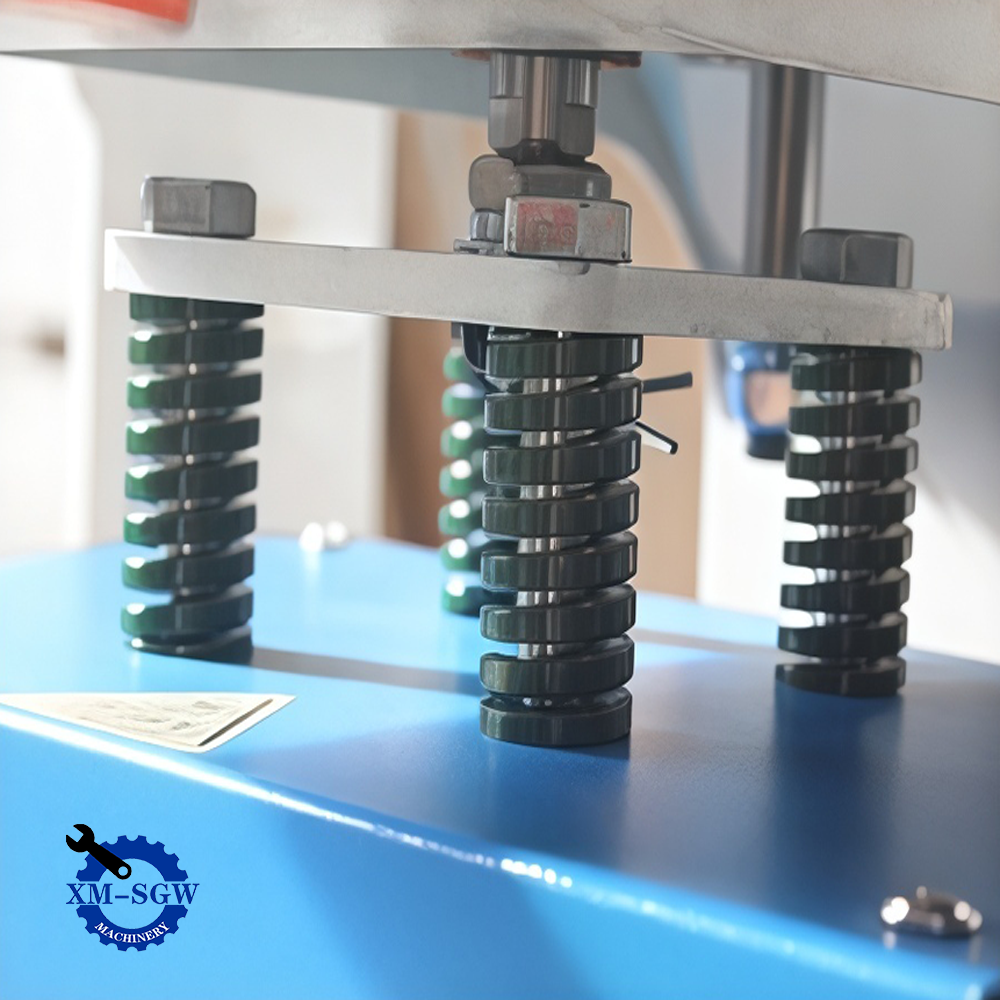

3. Precision Temperature & Pressure Control

Features advanced PID temperature regulation (±1℃ accuracy) and stepless adjustable pressure (0-1000N) to adapt to diverse materials (e.g., plastics, metals, textiles). Maintains stable thermal and pressure output throughout the process, guaranteeing uniform bonding/forming results.

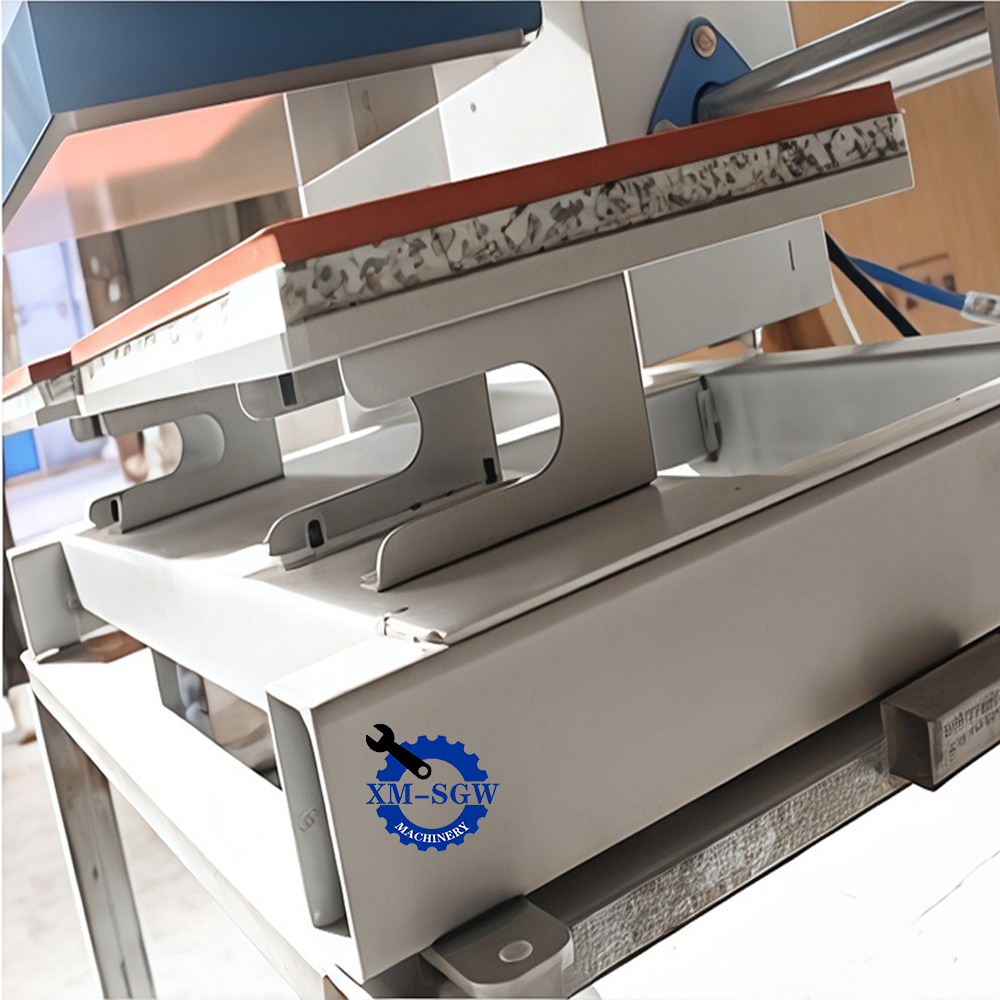

4. Semi-Automatic Operation for Efficiency

Combines manual loading/unloading with automated heat-press cycles (including timer-controlled holding time). Reduces manual labor intensity, shortens operation steps, and lowers the learning curve—new operators can master the machine in 30 minutes or less.

5. Durable Build for Long-Term Reliability

Constructed with high-strength aluminum alloy worktables and heat-resistant silicone pads (replaceable, 5000+ cycle lifespan). The laser module and heating element adopt industrial-grade components, ensuring stable performance even under 24/7 continuous operation, reducing maintenance costs.

6. Safety & Ergonomic Design

Equipped with dual safety interlocks (emergency stop button + door safety switch) to prevent accidental contact with high-temperature components. The worktable height is adjustable (700-900mm) to fit operators of different statures, reducing fatigue during long shifts.

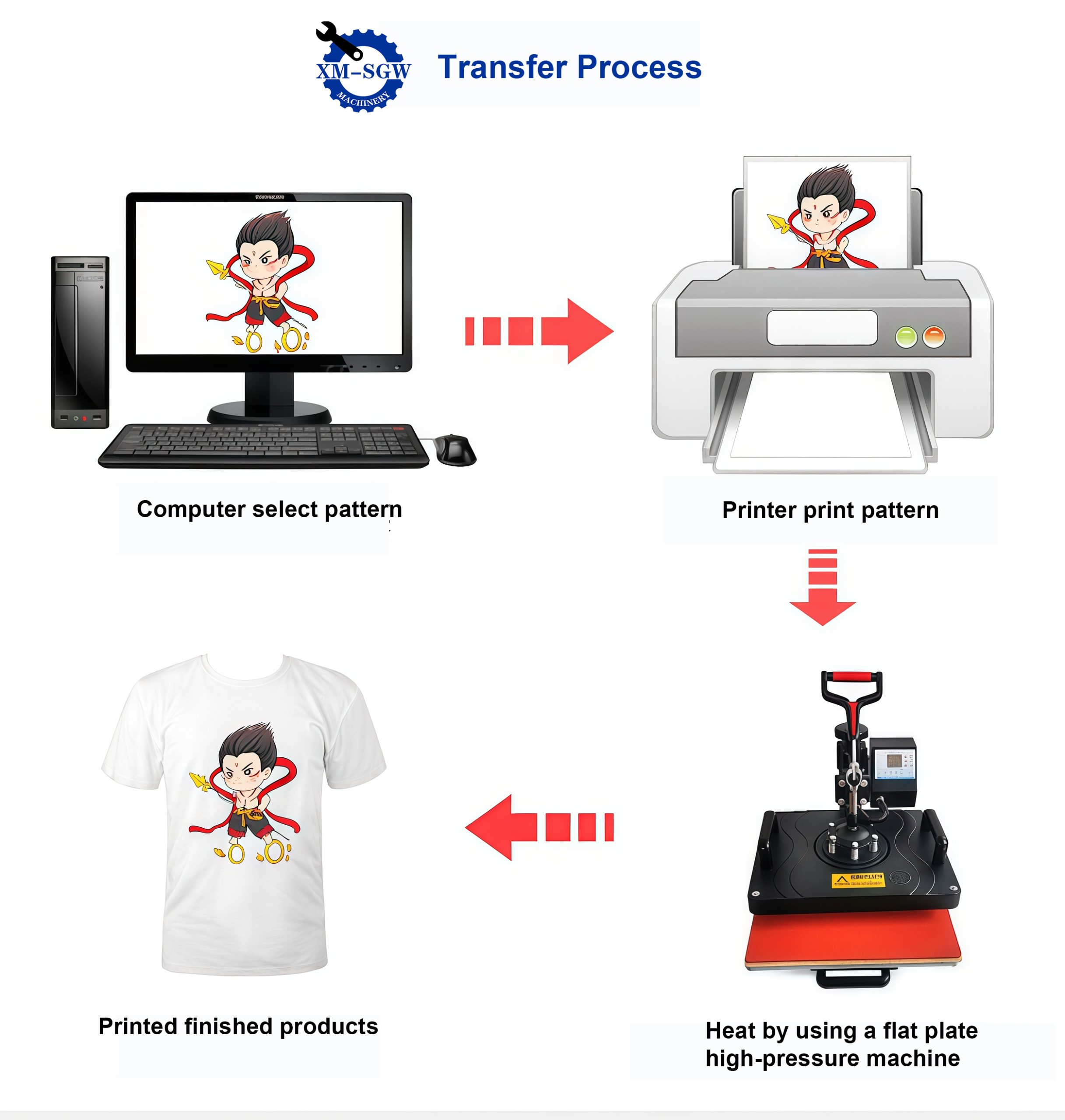

7. Wide Application Versatility

Suitable for multiple industries, including electronics (PCB bonding, component soldering),packaging (laminate sealing), automotive (small plastic part forming), and textiles (heat transfer printing).

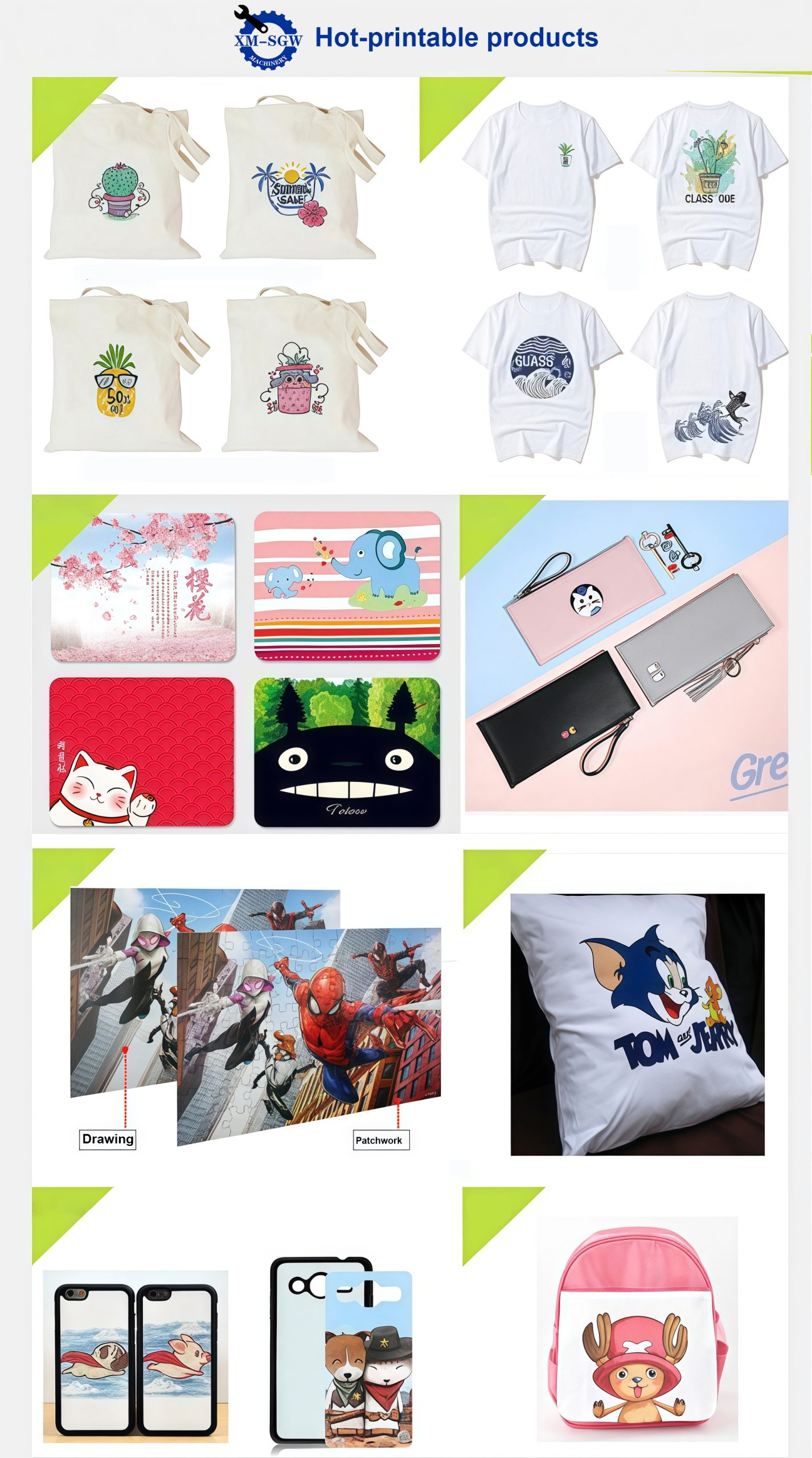

Hot Pressing Machine Applications

Double-station Hot Pressing Machine for T-shirt Video

Get Free Quote of Double-station Laser Positioning 20*20cm Hot Pressing Machine for T-shirt

Related Products

Related News

In manufacturing and processing industries, the hot press machine stands as a pivotal piece of equipment, enabling the bonding, shaping, […]

In a world where first impressions matter, the way your products look can make or break a sale. Whether you’re […]

In the world of manufacturing, packaging, and printing, hot stamping machines have revolutionized how businesses add elegance, brand recognition, and […]