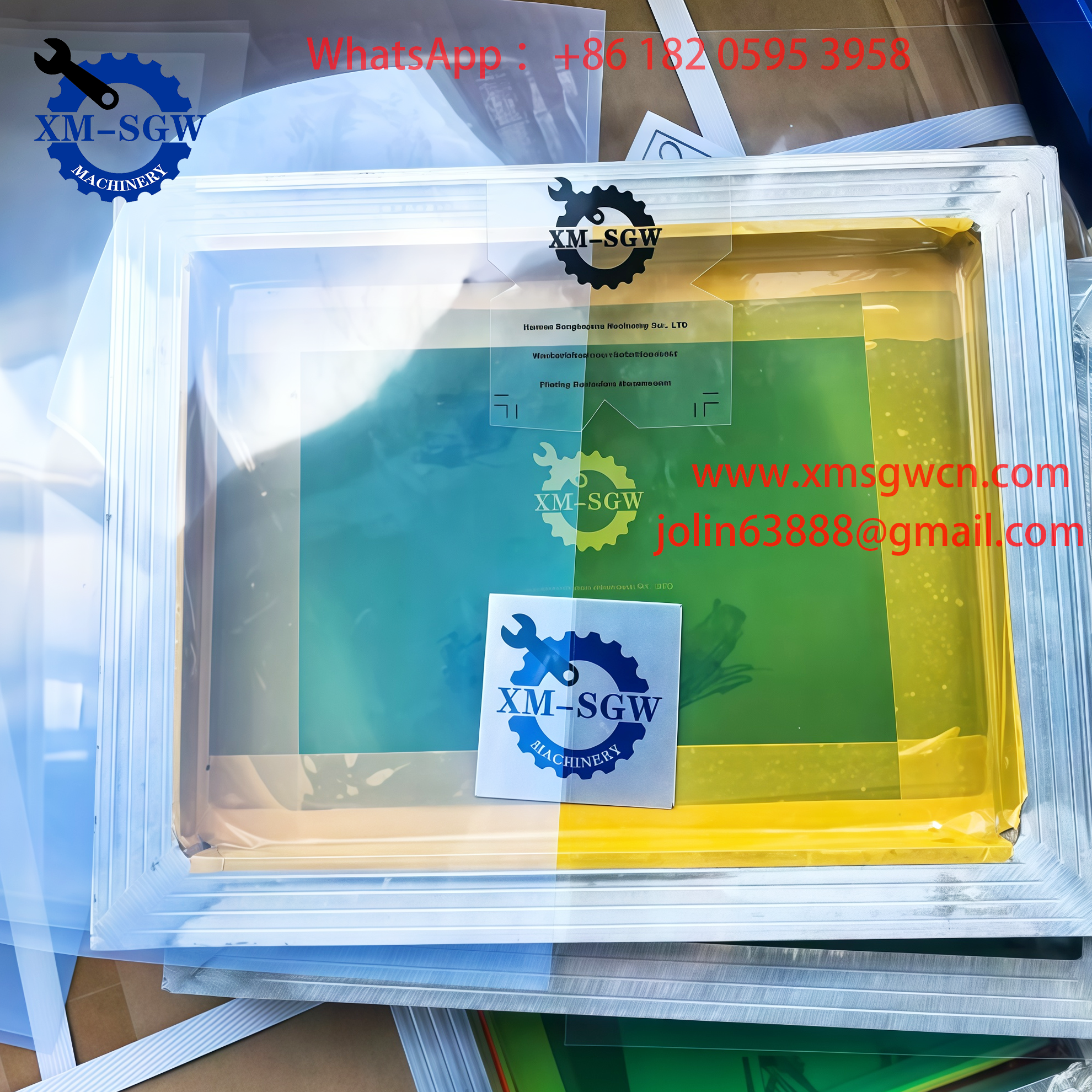

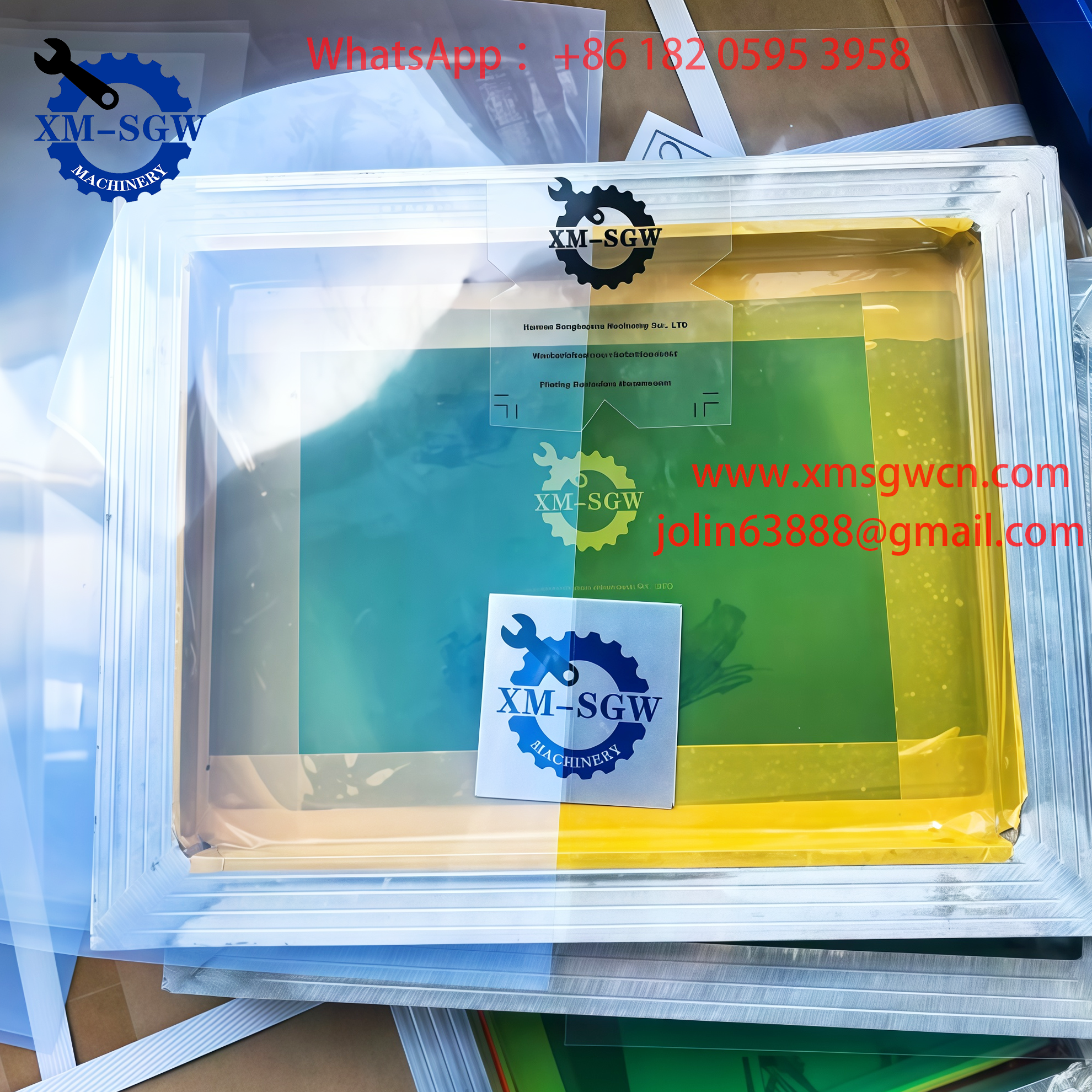

SGW High-Quality A3 A4 A3+ Waterproof Transparent Film Sheet for Screen Printing Plate Making

1. Ultra-high resolution for sharp, no-blur printing plates

2. Scratch-resistant coating

3. Fast-developing formula: cuts down your prep time

4. Compatible with screen/pad printing: one film for multiple needs

5. Consistent thickness: zero distortion for precise image transfer

6. Light-tight performance: preserves patterns without fading

Products Categories

Get A Free Quote

Film Sheet for Screen Printing Plate Making Description

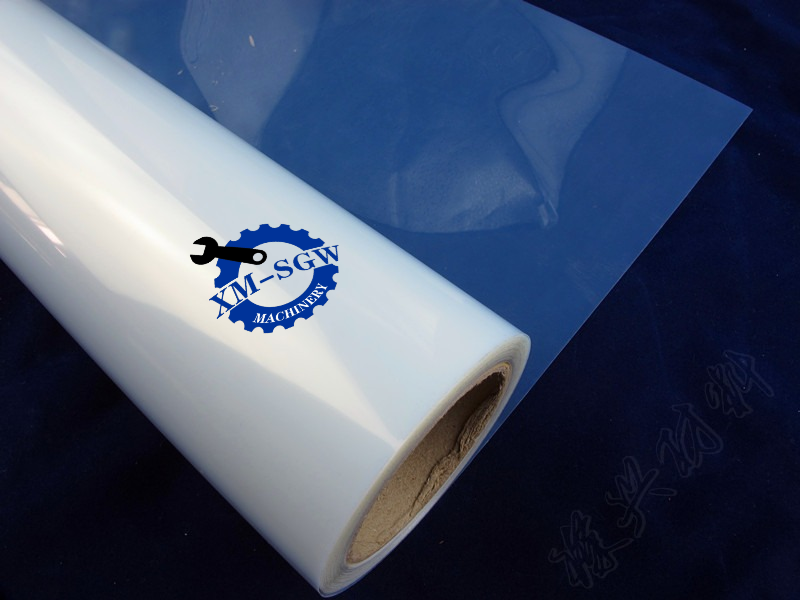

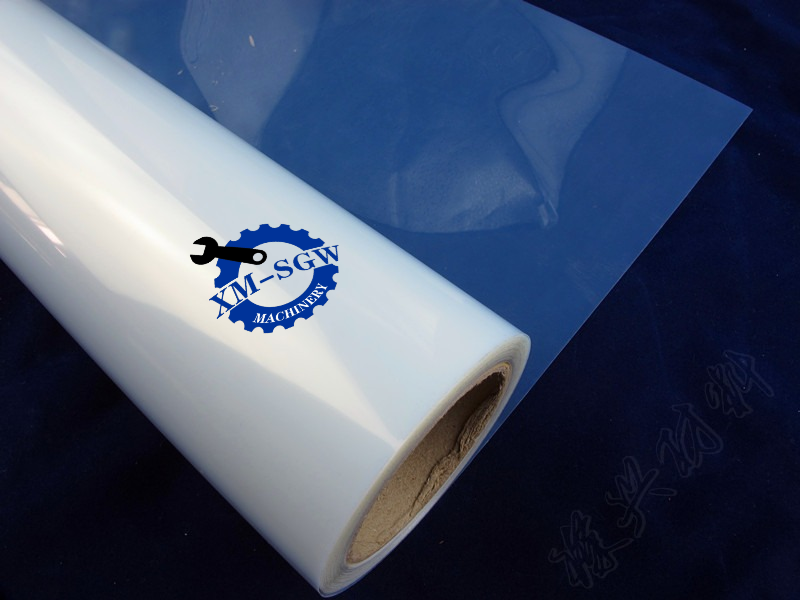

Transparent Film Sheet

Screen Printing Application Scenarios:Ideal for making positive plates; suitable for printing patterns with fine lines, small characters and gradient effects

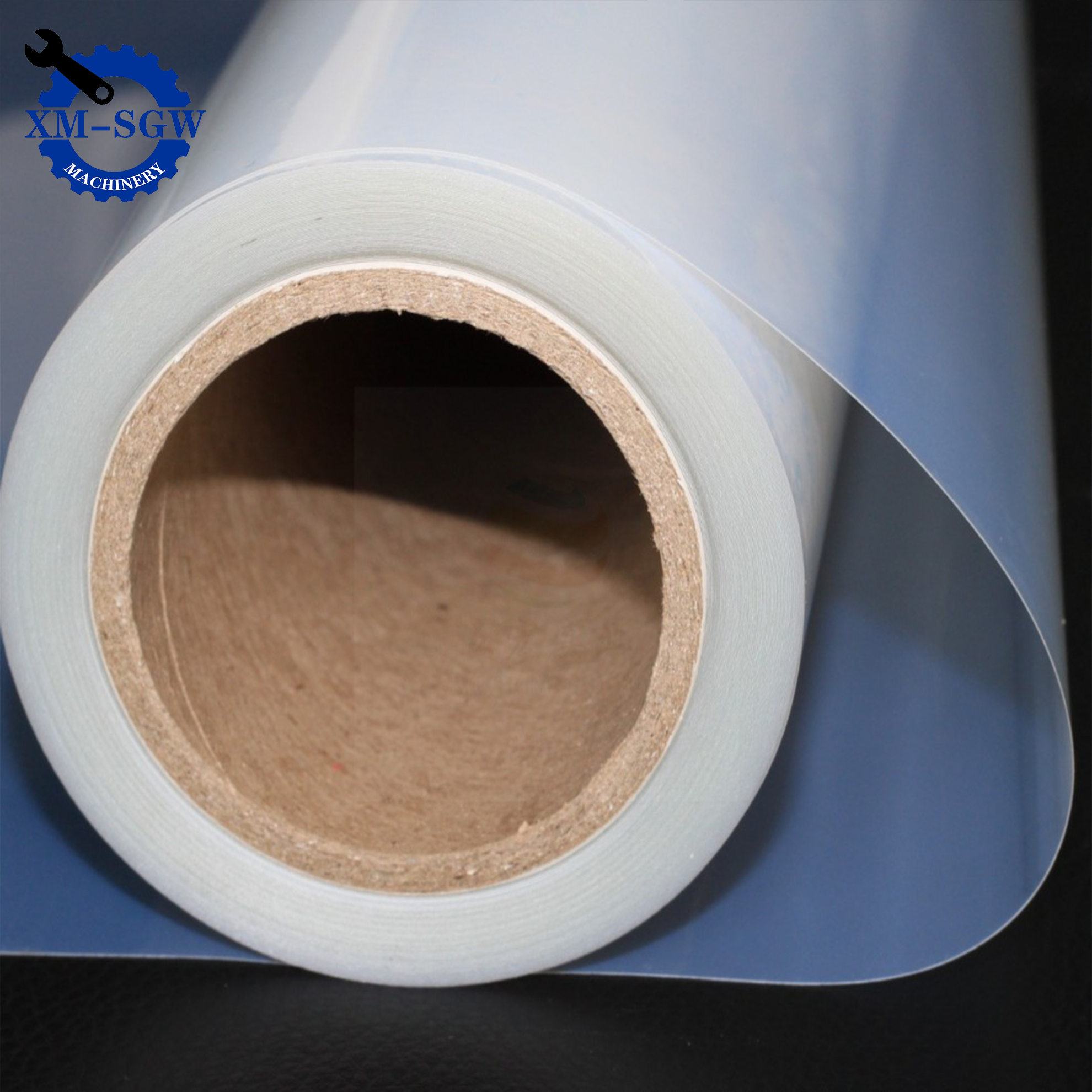

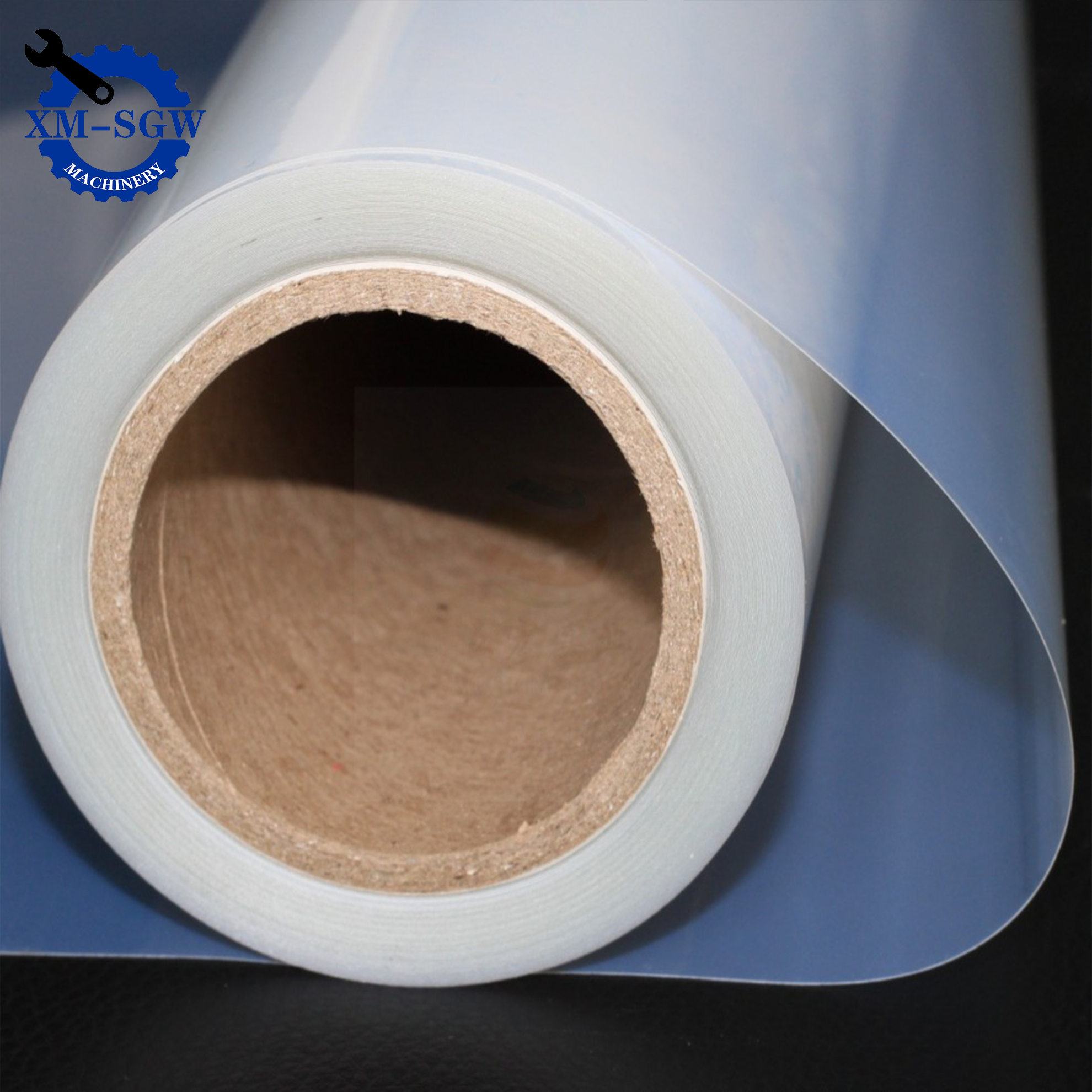

Milky White Film Sheet

Screen Printing Application Scenarios:Perfect for making negative plates or stencil plates; widely used in printing large-area solid patterns, such as logos, signs and packaging backgrounds

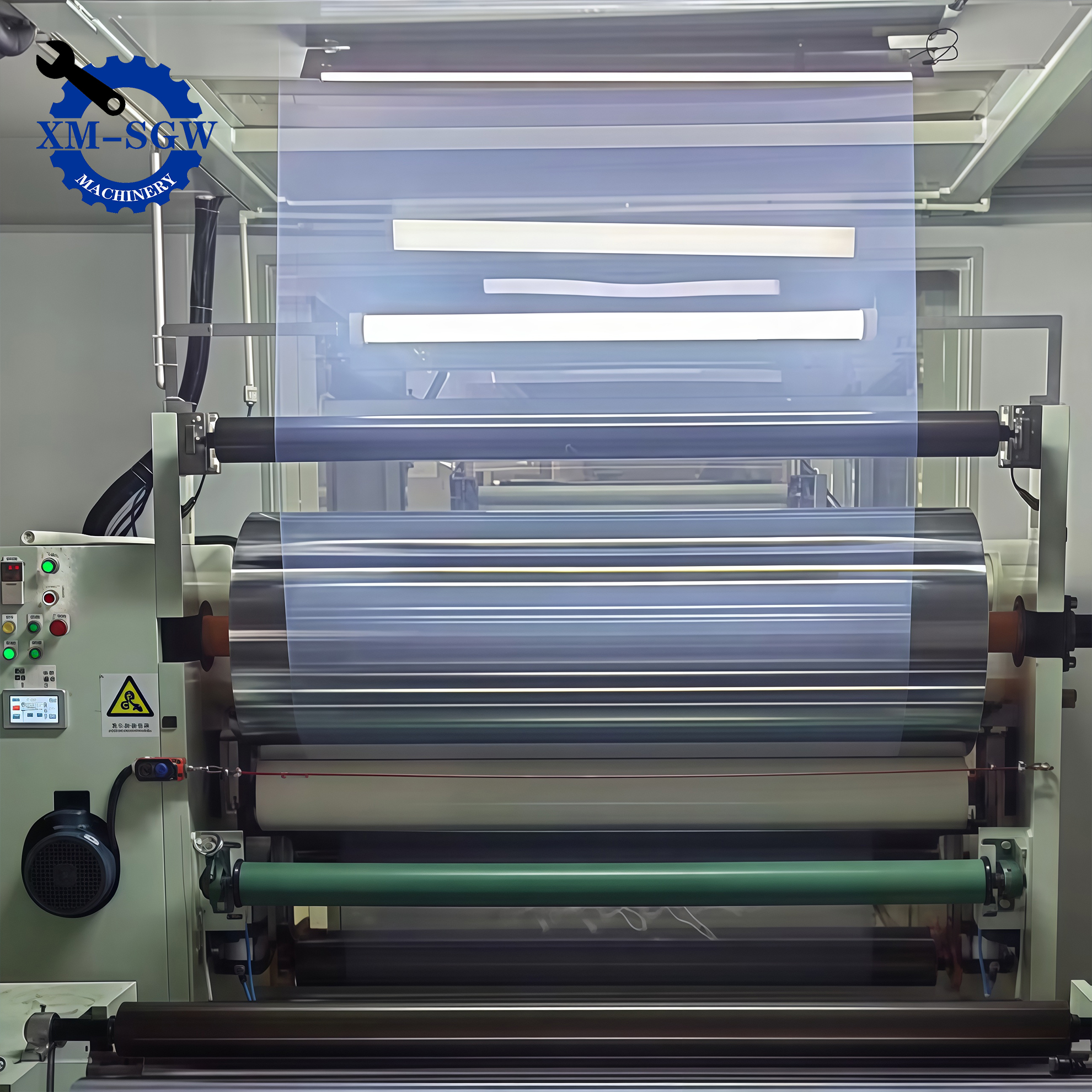

High-quality Materials

*Select high-quality PET materials *Smooth surface with no scratches *High toughness and does not turn yellow

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Film Sheet for Screen Printing Plate Making Detail Display

Film Sheet for Screen Printing Plate Making

|

item

|

value

|

|

Place of Origin

|

China

|

|

Fujian

|

|

|

Industrial Use

|

Silk screen printing

|

|

Material

|

PET, PET Film

|

|

Brand Name

|

SGW

|

|

Logo printing

|

Customizable

|

|

Thickness

|

50/75/100/125/175/250mic or Customized

|

|

Features

|

High Density; High Ink Dots; High Ink Absorption

|

|

Surface

|

Smooth

|

|

Size

|

A3;A4;A3+;12”;17”18”;22”;24”;26”*30m/50m

|

|

Packing

|

For Sheet: 100 sheets/per bag

|

|

Certificate

|

CE Certificate

|

|

Usage

|

Inkjet Film for Screen Printing,

|

Film Sheet for Screen Printing Plate Making

Application Scenarios of Transparent/Milky White Film Sheet

* Screen Printing Positive Plate Making

Ideal for producing positive plates for fine pattern printing, such as electronic circuit boards, precision instrument labels,

and gradient pattern packaging. High light transmittance ensures accurate exposure transfer of fine lines, tiny characters

(≤0.1mm) and complex gradient effects, with no edge blurring of the plate pattern.

* Digital Proofing & Design Draft Transmission

Serves as a high-precision proofing medium for pre-printing design drafts. Designers can overlay it on substrates (paper,

plastic, metal) to check pattern matching, color positioning and size accuracy before mass plate making, reducing

Ideal for producing positive plates for fine pattern printing, such as electronic circuit boards, precision instrument labels,

and gradient pattern packaging. High light transmittance ensures accurate exposure transfer of fine lines, tiny characters

(≤0.1mm) and complex gradient effects, with no edge blurring of the plate pattern.

* Digital Proofing & Design Draft Transmission

Serves as a high-precision proofing medium for pre-printing design drafts. Designers can overlay it on substrates (paper,

plastic, metal) to check pattern matching, color positioning and size accuracy before mass plate making, reducing

revision costs.

* Offset Printing Plate Pre-production

Used in the pre-press stage of offset printing to make film originals. It can be directly used for plate copying after being

output by a laser imagesetter, suitable for high-end printing products like magazines, brochures and product manuals

* Offset Printing Plate Pre-production

Used in the pre-press stage of offset printing to make film originals. It can be directly used for plate copying after being

output by a laser imagesetter, suitable for high-end printing products like magazines, brochures and product manuals

with rich details.

* Screen Printing Negative Plate/Stencil Making

Perfect for making negative plates for large-area solid pattern printing, including billboard logos, textile printing (T-shirt

patterns, fabric labels), and packaging box background colors. Its strong light-blocking property prevents backlight

penetration during exposure, avoiding pattern distortion caused by light reflection and ensuring uniform solid color

Perfect for making negative plates for large-area solid pattern printing, including billboard logos, textile printing (T-shirt

patterns, fabric labels), and packaging box background colors. Its strong light-blocking property prevents backlight

penetration during exposure, avoiding pattern distortion caused by light reflection and ensuring uniform solid color

printing without color halos.

* Pad Printing Plate Production

Applied to pad printing plate making for irregular surface products (curved plastic parts, spherical objects, electronic

buttons). The matte surface reduces glare during plate making, and the opaque texture ensures that the pattern edge is

Applied to pad printing plate making for irregular surface products (curved plastic parts, spherical objects, electronic

buttons). The matte surface reduces glare during plate making, and the opaque texture ensures that the pattern edge is

neat,which is conducive to the transfer of small-area solid patterns.

* Screen Printing for Thick Film Circuits

Used in the production of thick film circuit plates for electronic components. It can block the scattering of ultraviolet light

during exposure, ensuring the thickness uniformity of the circuit pattern and improving the conductivity stability of the

finished circuit.

Used in the production of thick film circuit plates for electronic components. It can block the scattering of ultraviolet light

during exposure, ensuring the thickness uniformity of the circuit pattern and improving the conductivity stability of the

finished circuit.

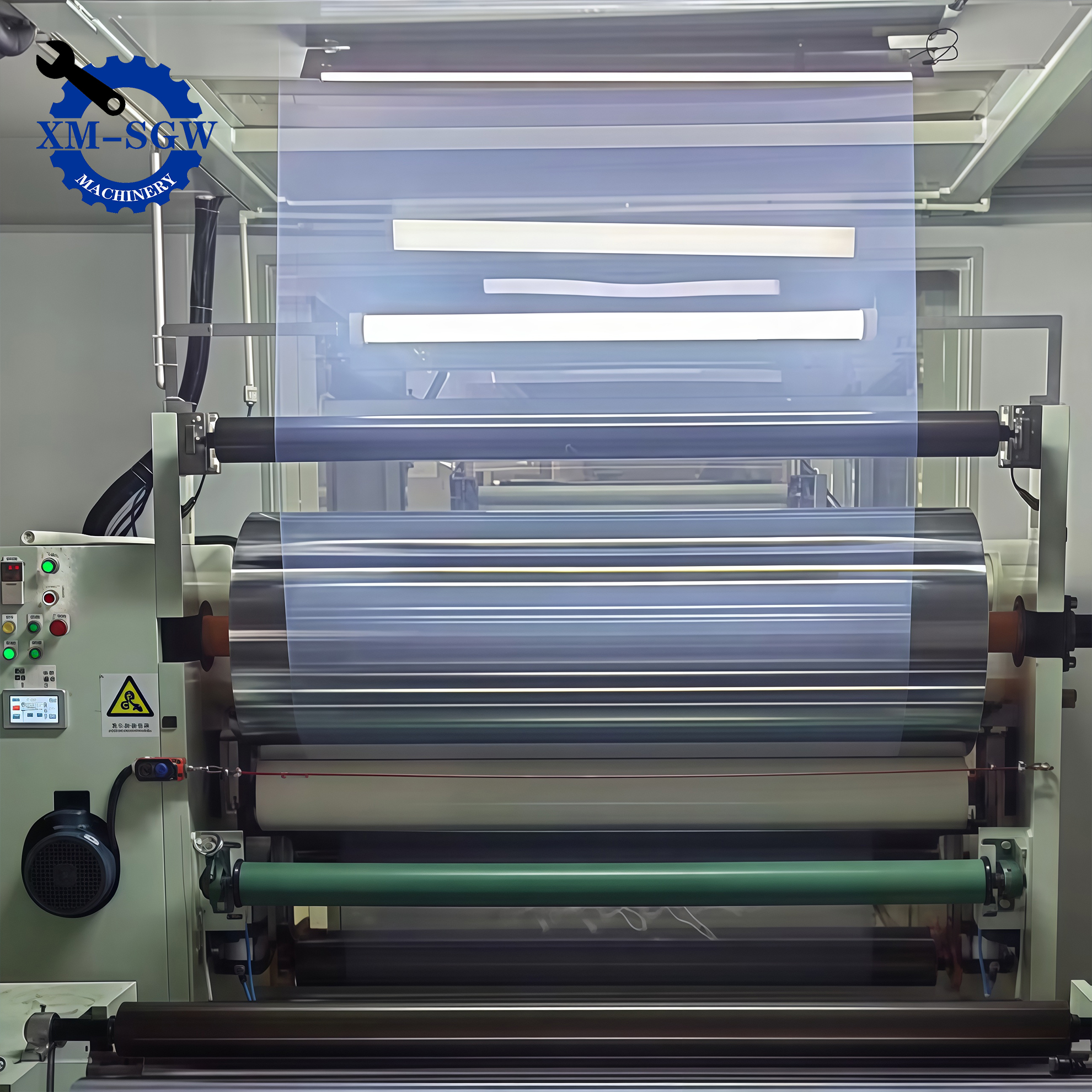

Film Sheet for Screen Printing Plate Making Video

Get Free Quote of Film Sheet for Screen Printing Plate Making

Related News

Screen printing is a versatile and widely used printing technique, favored by businesses and hobbyists alike for its ability to […]

In the world of screen printing, even the smallest inconsistency can ruin a batch of products. From misaligned graphics to […]

In the world of screen printing, every detail matters. From ink selection to machine calibration, each element plays […]