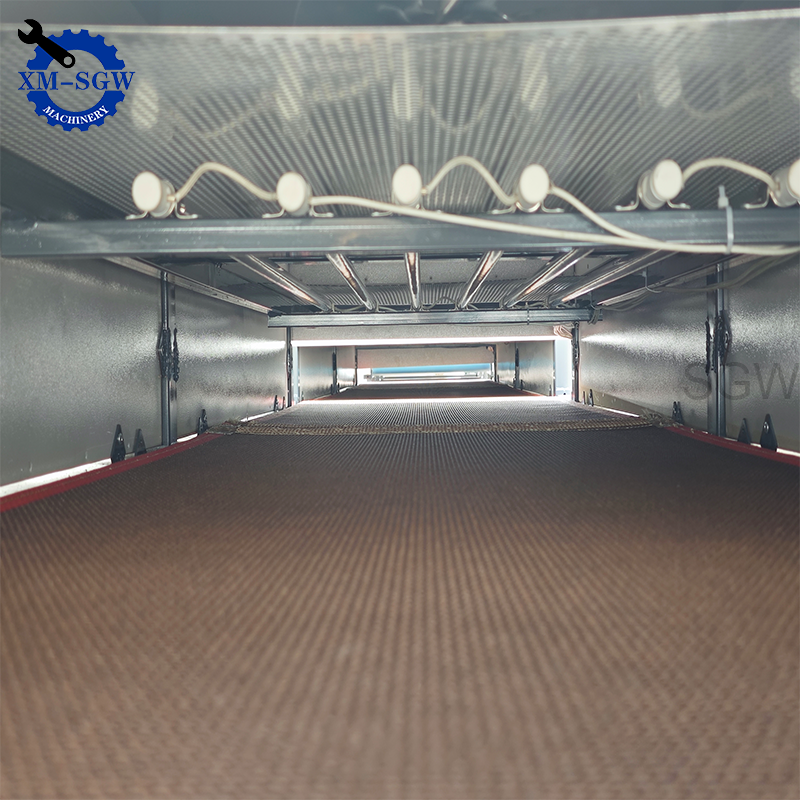

Tunnel IR Dryer High-Efficiency Industrial Drying Machine

- Continuous High-Efficiency Production Tunnel + conveyor belt design enables 24/7 non-stop operation. 35% faster drying speed than traditional hot-air dryers, supporting bulk processing (customizable capacity up to 800kg/h) and boosting throughput.

- Energy-Saving & Cost-Effective Targeted infrared heating reduces heat loss by 30%. No massive air circulation required, cutting long-term energy costs significantly for industrial production.

- Wide Industry Compatibility Perfect for screen printing (ink curing), hardware (coating drying), food (nuts/fruit crisps, GMP-compliant), electronics (PCB curing) and auto parts. Adjustable speed (0.5-5m/min) & temp (30-250℃) fits diverse materials.

- Smart Automation & Easy Operation: one-key start/stop, precise parameter setting. No professional operator needed, reducing labor costs by 20%.

- Customizable Solutions Tailor belt width (0.5-2m), drying zone length (2-10m), heat source (electric/gas) and exhaust system to match your production line.

Products Categories

Get A Free Quote

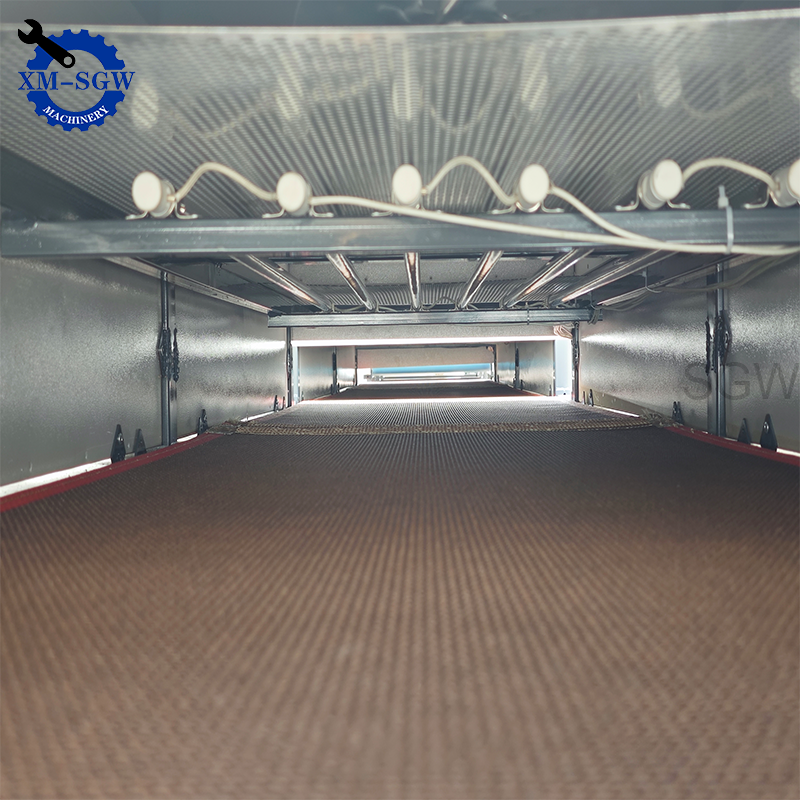

Tunnel IR Dryer Description

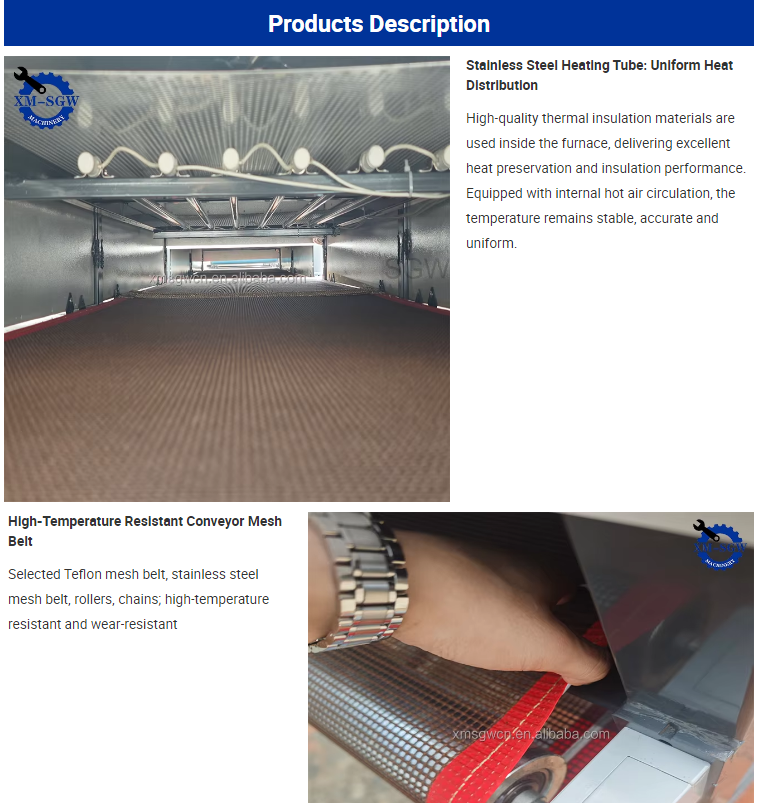

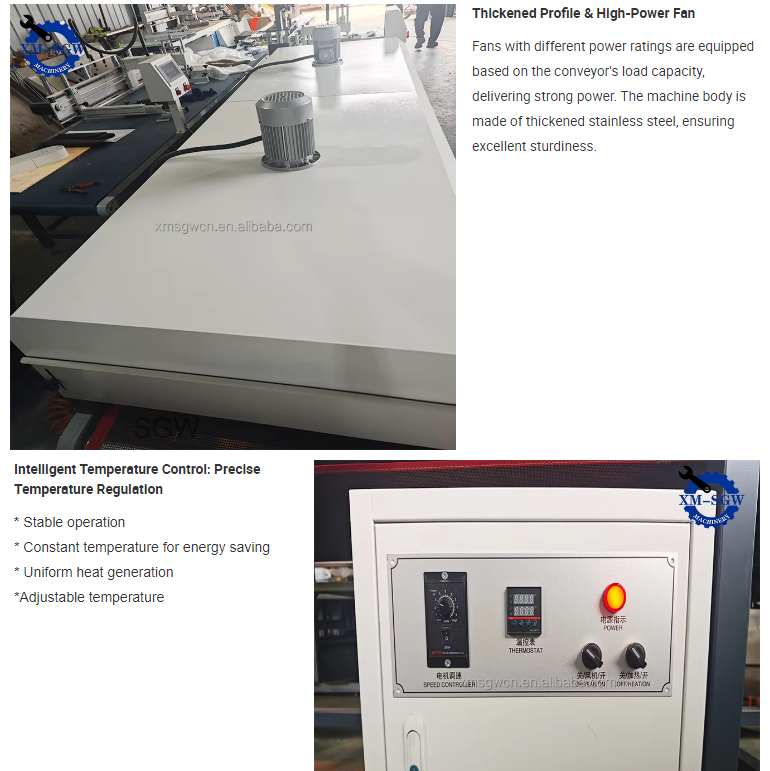

Tunnel IR Dryer Detail Display

Tunnel IR Dryer Data Sheet

Tunnel IR Dryer Applications

Tunnel IR Dryer Video

Get Free Quote of Tunnel IR Dryer

Related News

Tunnel Type Infrared Dryer: The Efficient, Energy-Saving Solution for Industrial Drying In the realm of industrial manufacturing and processing, […]

In today’s fast-paced manufacturing landscape—where speed, sustainability, and precision are non-negotiable—UV curing machines have emerged as a game-changer. Unlike traditional […]