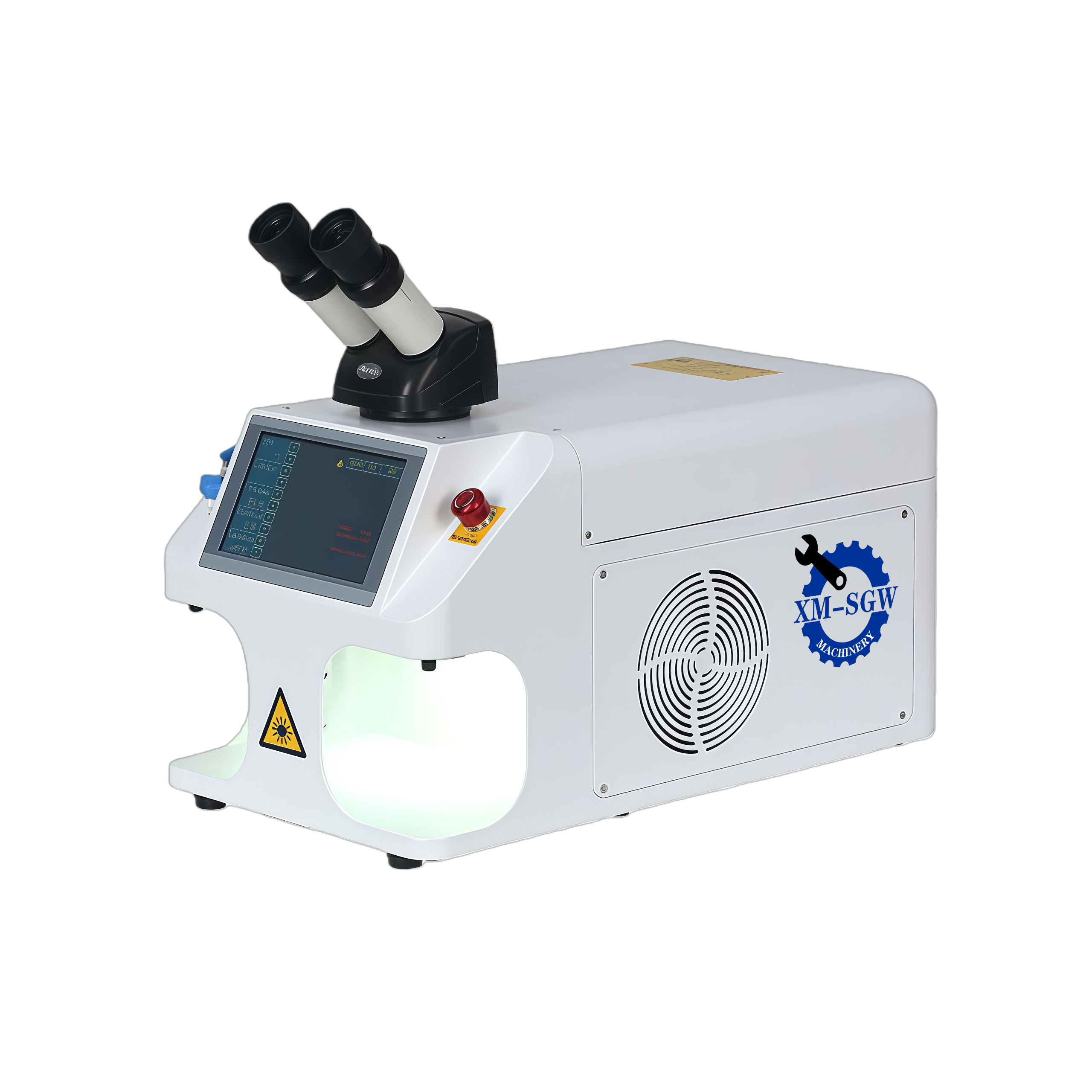

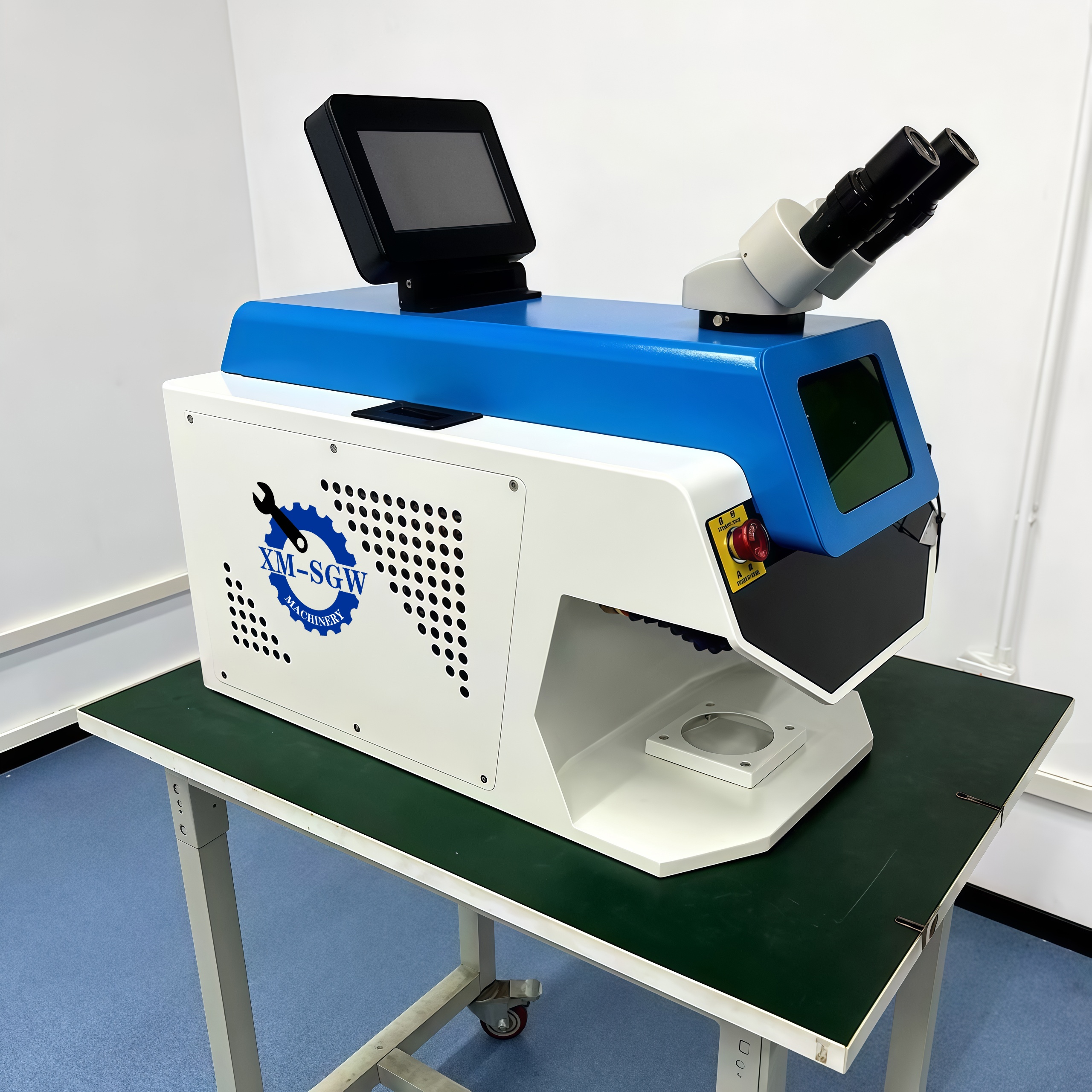

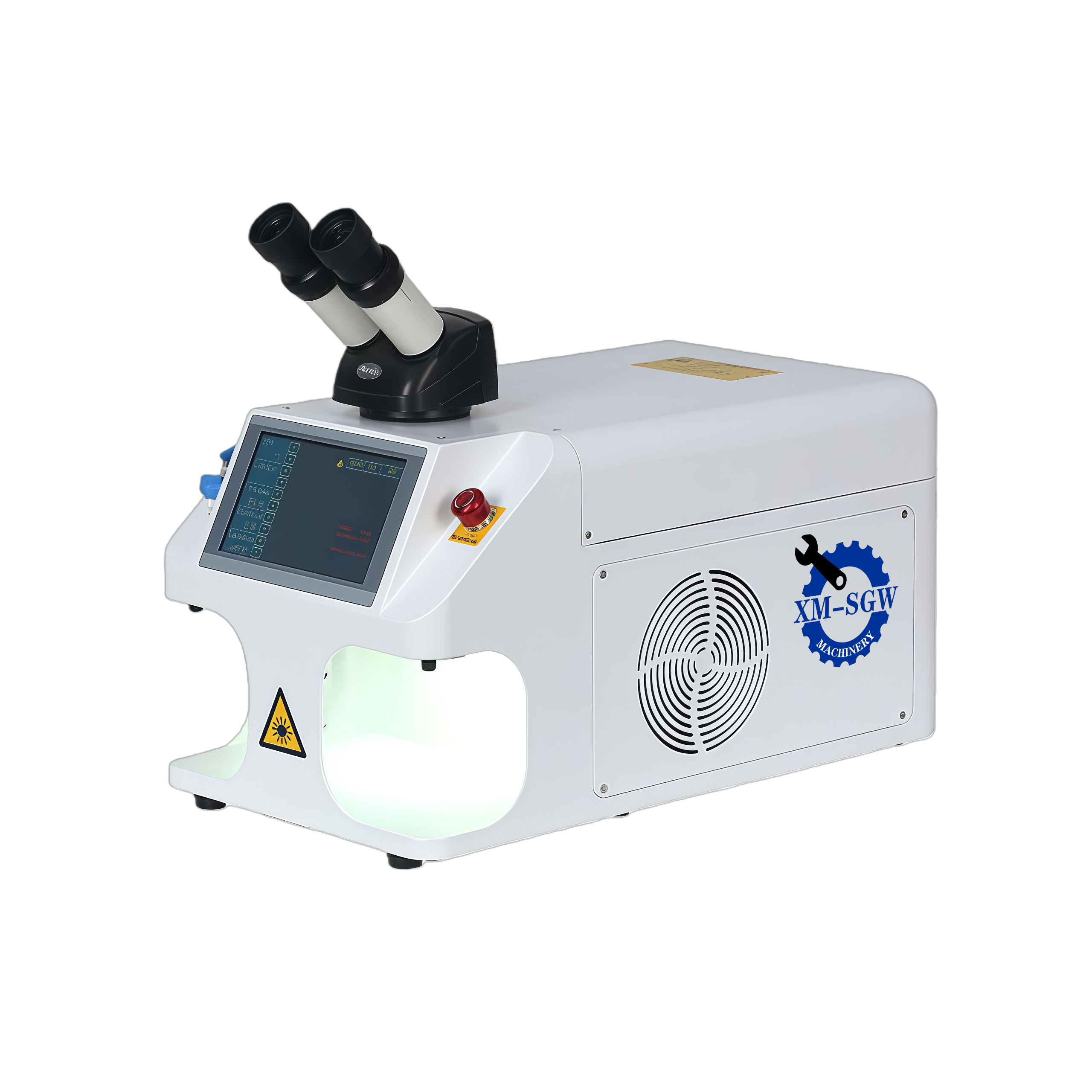

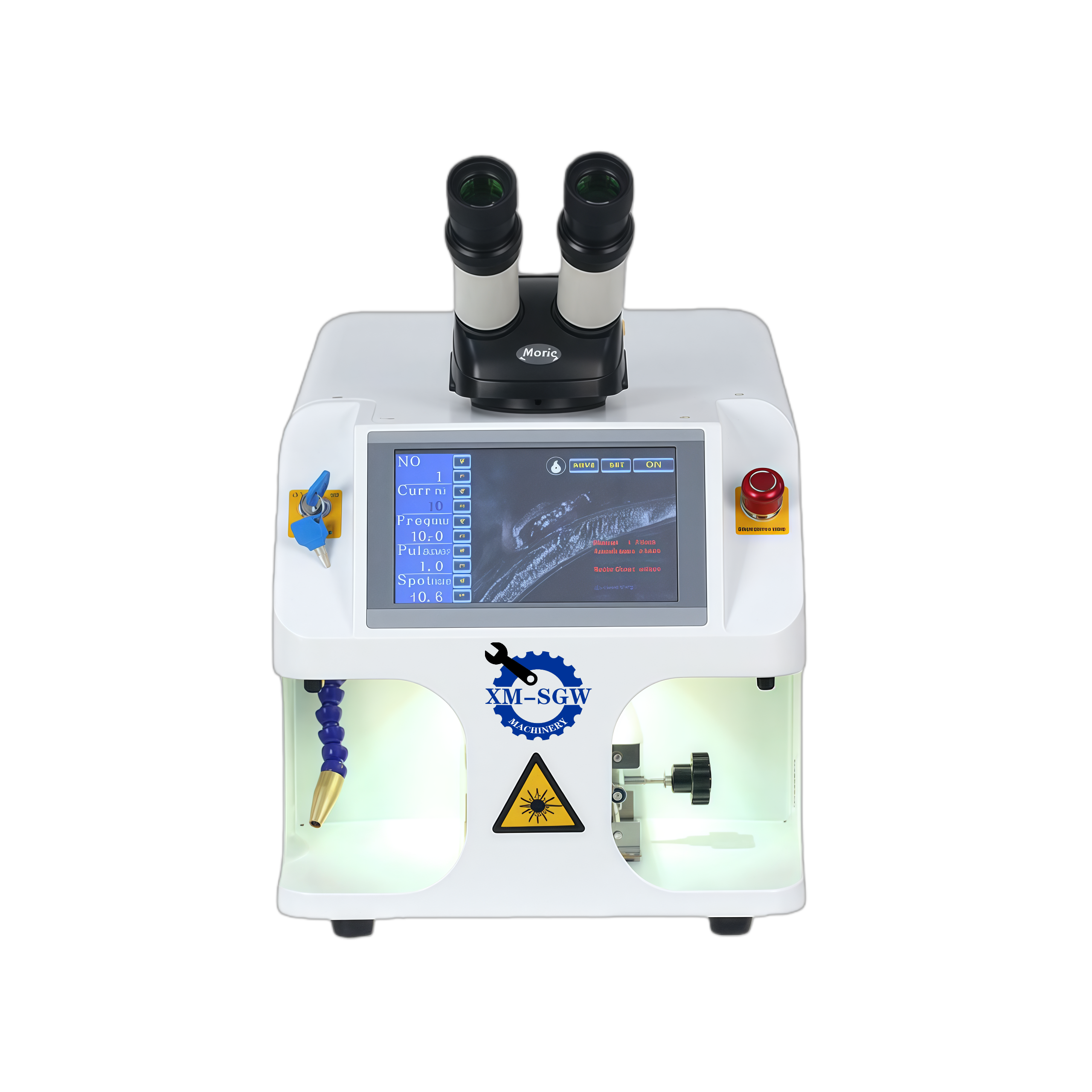

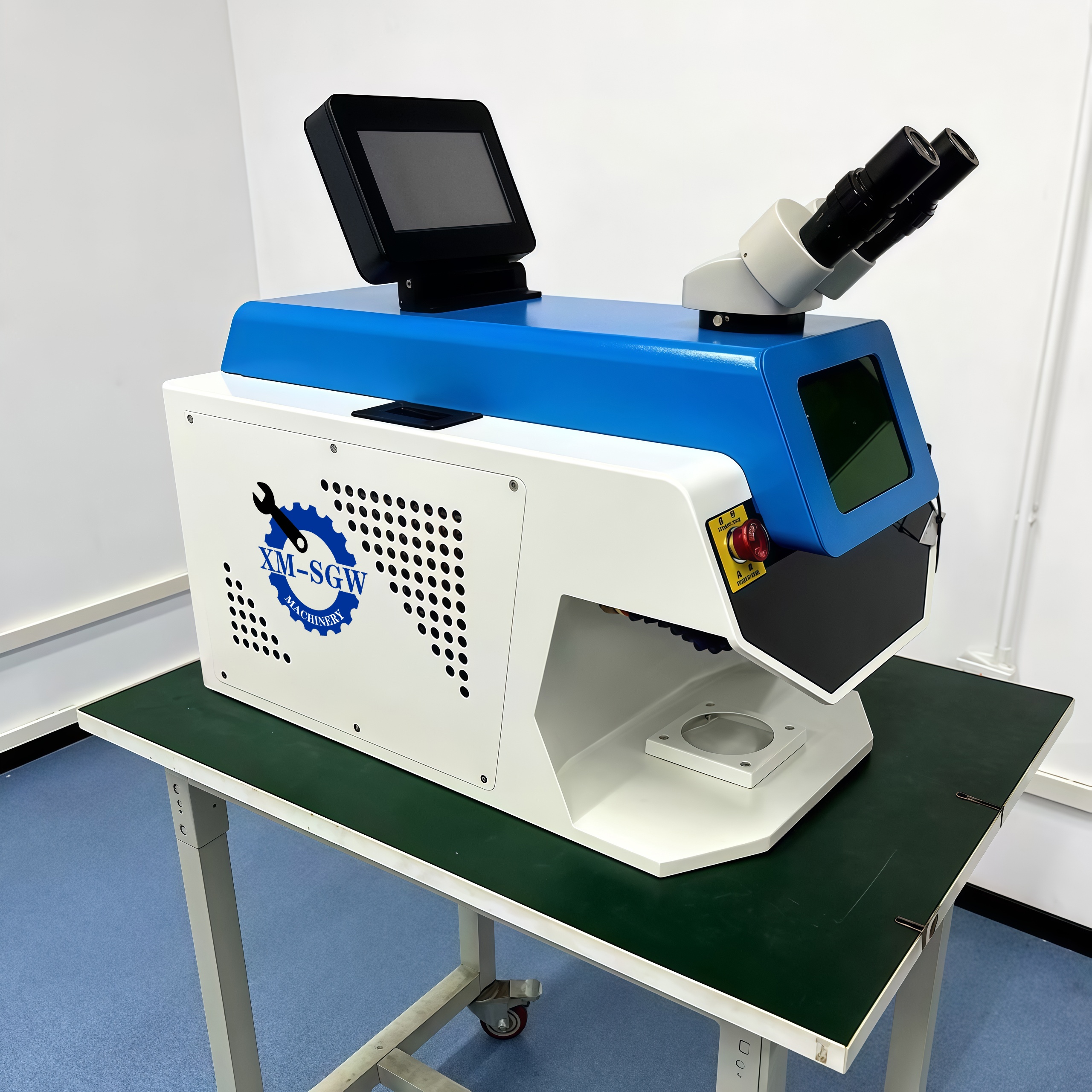

SGW High Precision Jewelry Laser Welding Machine Desktop Type for Ring Resizing and Chain Repair

-

High Efficiency: Fast welding speed, 3-5 times that of traditional welding, improving production efficiency significantly.

-

Superior Weld Quality: Smooth, firm and beautiful welds, no pores or cracks, reducing subsequent polishing workload.

-

Cost-Effective: Low energy consumption, simple maintenance, no need for filler metal, reducing production and maintenance costs.

-

Space-Saving: Desktop design fits small workshops and laboratories, solving the problem of insufficient space.

-

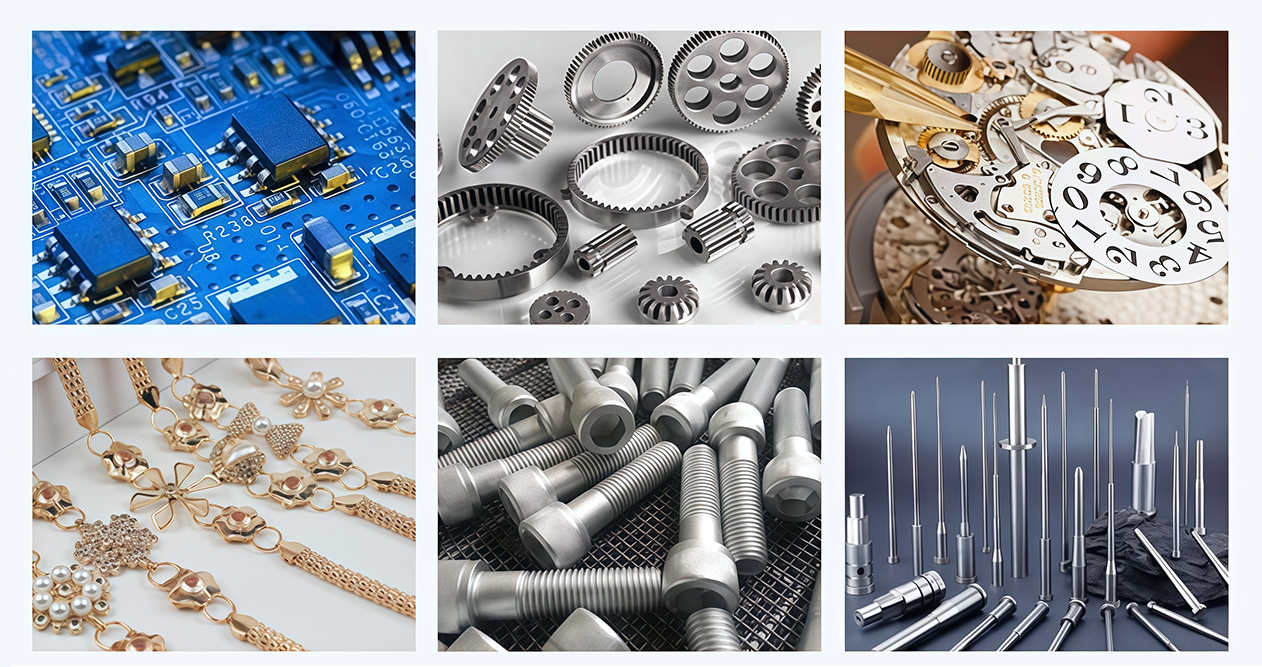

Versatile Application: Suitable for small and medium-sized workpieces, widely used in electronics, jewelry, hardware, auto parts and other industries.

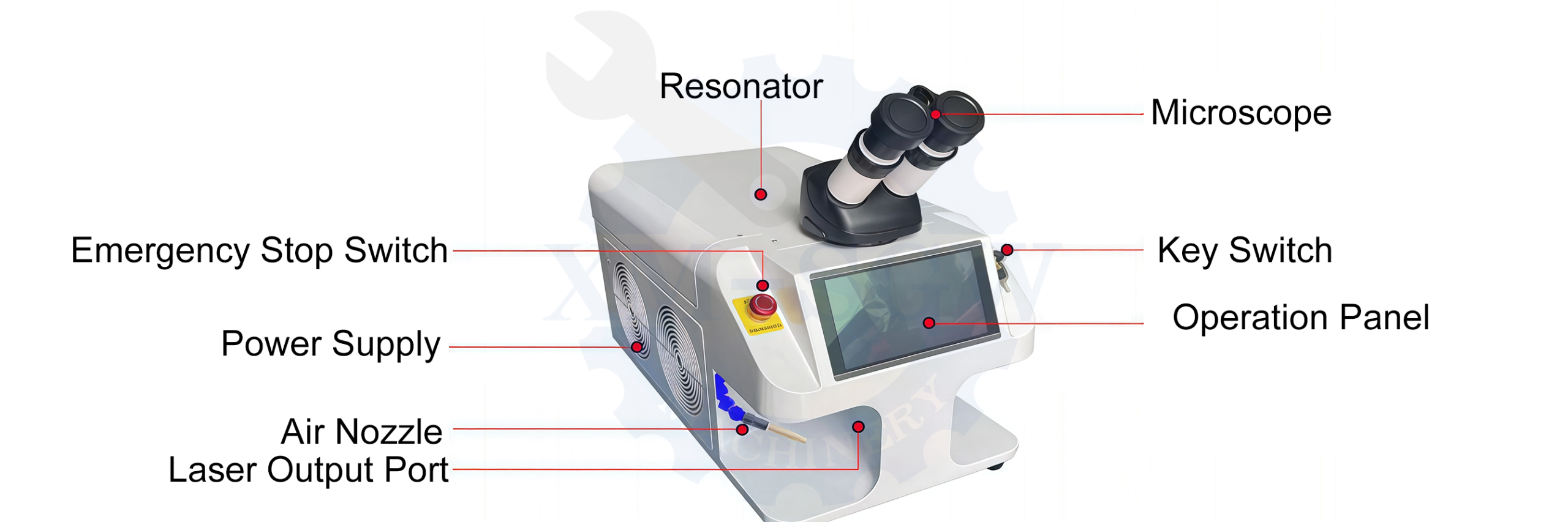

Jewelry Laser Welding Machine Description

Jewelry Laser Welding Machine Data Sheet

|

item

|

value

|

|

Laser Welding Depth

|

0.1-3.0mm

|

|

Pulse Width

|

0.1-20ms

|

|

Laser Wavelength

|

1064nm

|

|

Adjustable Spot Size Range

|

0.2-3mm

|

|

Total Power Consumption

|

≤6kW

|

|

Power Supply Requirement

|

AC220V±10%/50Hz 30A

|

|

Cooling Method

|

Water Cooling

|

|

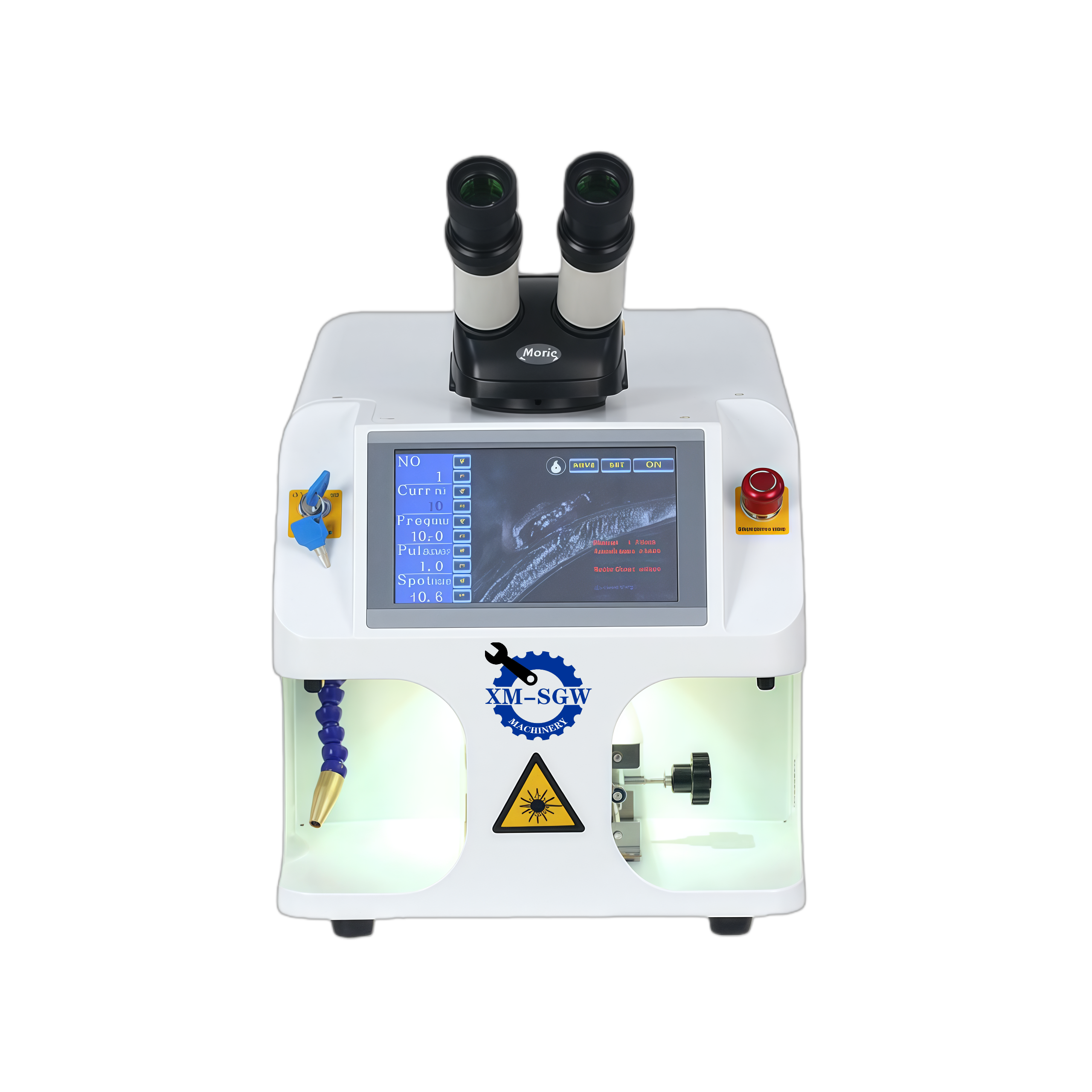

Observation System

|

10x Microscope or High-Definition CCD

|

|

Shielding Gas

|

Argon Gas

|

|

Laser Power

|

200W

|

Jewelry Laser Welding Machine Applications

1. Jewelry Repair Studios

* Application: Daily repair of broken chains, resizing rings, fixing loose gem settings, and reattaching clasps on gold, silver,

and platinum jewelry.

* Why It Fits: The built-in magnifying lens and 10x microscope ensure pinpoint precision for tiny repairs, while the intuitive

large screen lets technicians adjust parameters quickly to achieve invisible, seamless welds.

2. Custom Jewelry Ateliers

* Application: Creating intricate custom pieces, such as micro-pavé settings, delicate filigree details, and personalized

engravings, as well as assembling complex multi-part designs.

* Why It Fits: The high-power YAG laser delivers consistent energy for fine, repeatable welds, and the adjustable spot

size/frequency adapts to the delicate demands of high-end custom work.

3. Brand Jewelry After-Service Centers

* Application: Fast, high-quality repairs for luxury jewelry brands, ensuring repairs meet the brand’s strict quality standards

without damaging precious materials.

* Why It Fits: The stable water-cooling system supports continuous all-day operation, and the argon gas shielding prevents oxidation, keeping the jewelry’s original finish intact.

* Application: Training students in jewelry fabrication, repair techniques, and laser welding fundamentals, with a focus on

safety and ease of use.

* Why It Fits: The user-friendly touchscreen and clear safety features (emergency stop, laser warnings) make it ideal for

teaching, while the compact desktop design saves space in classrooms.

5. Retail Jewelry Stores (In-Store Repair)

* Application: On-site, same-day repairs for customers, such as fixing a broken necklace or tightening a ring setting, to

* Why It Fits: The space-saving desktop design fits neatly behind counters, and the quick setup allows technicians to

Jewelry Laser Welding Machine

Related News

Elevate Your Welding Precision with Compact, Desktop-Ready Power For artisans, jewelers, and small-scale manufacturers, precision and efficiency are non-negotiable. Traditional […]

In the fast-paced world of manufacturing, warehousing, and customization, precision marking is no longer a luxury—it’s a necessity. From serial […]

In the realm of industrial marking and coding, precision, versatility, and efficiency are non-negotiable. CO₂ laser marking machines have emerged […]