Screen printing is a versatile and widely used printing technique, favored by businesses and hobbyists alike for its ability to produce high-quality prints on various substrates. However, the success of any screen printing project hinges on the quality of the supplies used—especially the core consumables: emulsion, film sheets, mesh, and frames. In this guide, we’ll break down each of these essential supplies, exploring their functions, key considerations when choosing them, and how they work together to deliver exceptional results.

1. Emulsion: The Foundation of Precise Stencils

Emulsion is a light-sensitive material that plays a critical role in creating the stencil (the pattern or design) on the screen. When exposed to light, it hardens, and the unexposed areas (the design) can be washed away, leaving a precise stencil that allows ink to pass through onto the substrate. Choosing the right emulsion is essential for achieving sharp, clean prints, and several factors should guide your selection.

First, consider the type of emulsion: dual-cure, photopolymer, or diazo. Dual-cure emulsions are the most versatile, combining the benefits of photopolymer (fast exposure times) and diazo (excellent durability), making them suitable for both water-based and solvent-based inks. Photopolymer emulsions are ideal for quick production runs and fine details, as they require no mixing and cure rapidly under UV light. Diazo emulsions, on the other hand, are more affordable and offer great resistance to harsh solvents, making them a popular choice for industrial applications.

Other key factors include emulsion viscosity (which affects how well it coats the mesh) and mesh compatibility. Thicker emulsions are better for creating stencils with higher ink deposits, while thinner emulsions are ideal for fine details. Always ensure the emulsion you choose is compatible with your mesh count and the type of ink you’ll be using to avoid issues like stencil breakdown or poor adhesion.

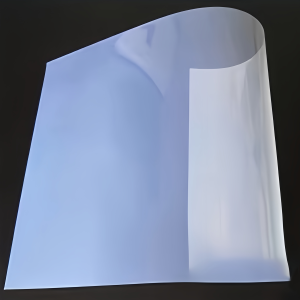

2. Film Sheets: Creating Clear, Accurate Designs

Film sheets (also known as transparency films) are used to create the negative of your design, which is then placed on top of the emulsion-coated screen during the exposure process. The quality of the film sheet directly impacts the clarity of the stencil—poor-quality films can result in blurry edges, missing details, or uneven exposure.

When selecting film sheets, look for options with high opacity. Opaque films block light effectively, ensuring that the emulsion under the design remains unhardened and can be washed away cleanly. Translucent films, by contrast, allow light to seep through, leading to distorted stencils. Additionally, consider the film’s thickness and durability: thicker films are less likely to tear or curl during handling, which is important for consistent results, especially in high-volume production.

For digital screen printing setups, choose film sheets that are compatible with your printer (inkjet or laser). Inkjet film sheets are coated to hold ink evenly, while laser film sheets are heat-resistant to withstand the laser printing process. Investing in high-quality film sheets will save you time and frustration by reducing the risk of misprints and rework.

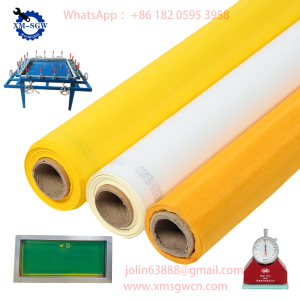

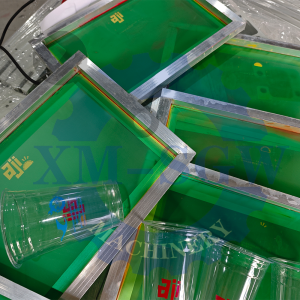

3. Mesh: Controlling Ink Deposit and Detail

The mesh is the porous material stretched across the frame, and it serves as the base for the stencil. The type and specifications of the mesh determine how much ink is deposited on the substrate and how fine the details of the print can be. Mesh is defined by its “mesh count”—the number of threads per inch (or centimeter). A higher mesh count means more threads per inch, resulting in a finer screen that produces sharp, detailed prints with less ink deposit. A lower mesh count has larger openings, allowing more ink to pass through, making it ideal for bold, opaque prints on dark substrates.

Mesh material is another important consideration. Polyester mesh is the most common choice due to its durability, resistance to chemicals (from inks and cleaners), and consistent tension. Nylon mesh, while more elastic, is less resistant to solvents and is typically used for specialty applications. Stainless steel mesh is extremely durable and heat-resistant, making it suitable for high-temperature printing processes or abrasive inks.

When choosing mesh, match the mesh count to your design and substrate. For example, a 110-156 mesh count is ideal for general-purpose printing (e.g., t-shirts, posters), while a 200-305 mesh count is better for fine details (e.g., logos, text). Always ensure the mesh is properly stretched and tensioned—loose mesh can lead to blurred prints and uneven ink coverage.

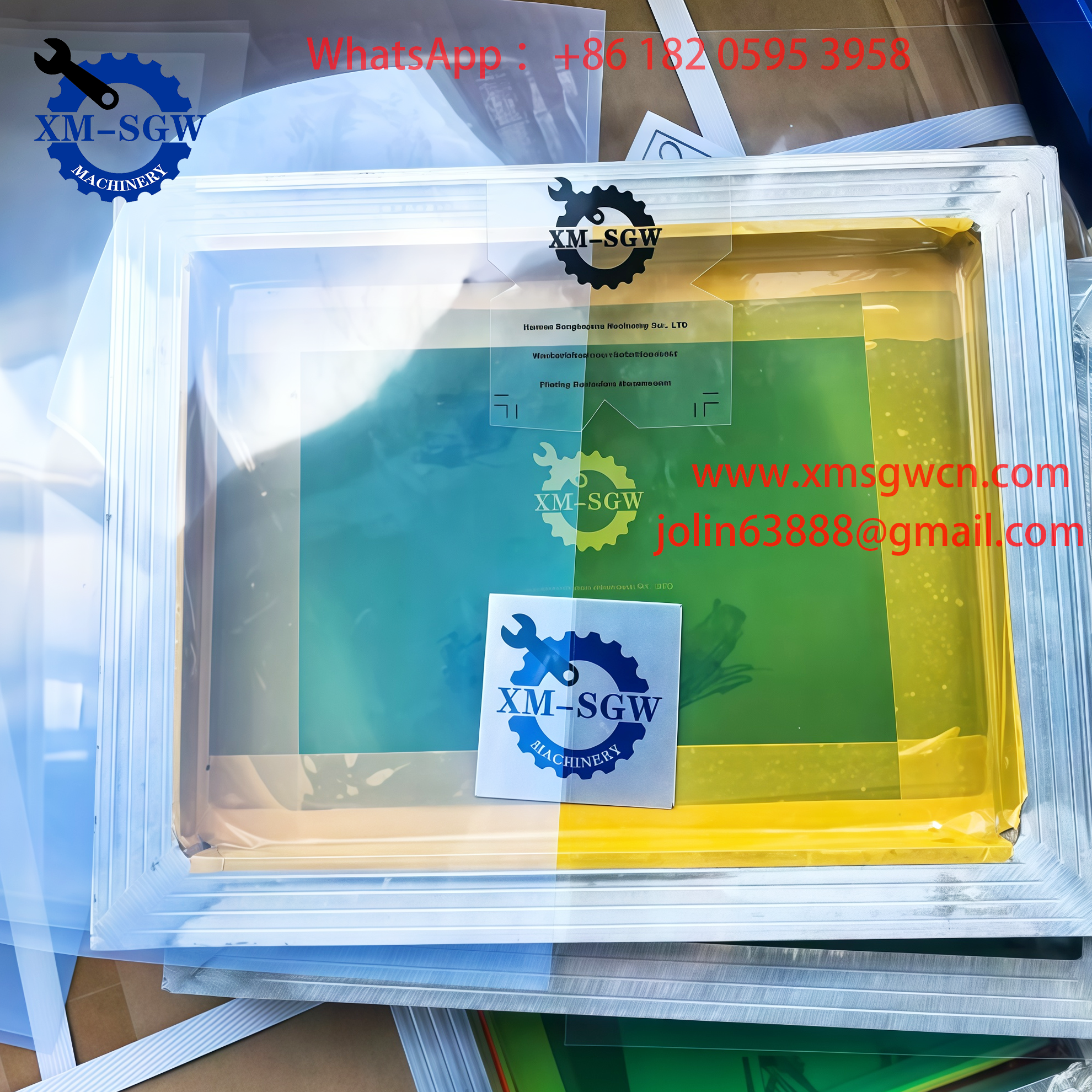

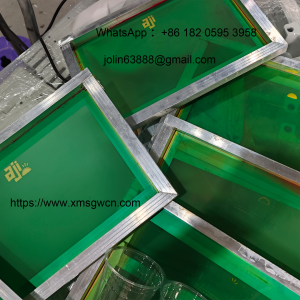

4. Frames: Providing Stability and Tension

Frames are the backbone of the screen printing setup, providing the structure that holds the mesh taut. A high-quality frame ensures consistent tension (critical for sharp prints) and durability, reducing the need for frequent replacements. Frames are available in various materials, each with its own advantages and applications.

Aluminum frames are the industry standard due to their lightweight, durability, and resistance to warping. They are easy to handle, making them ideal for both small-scale and large-scale production. Wooden frames are a more affordable option, suitable for hobbyists or low-volume printing. However, wooden frames are prone to warping and absorbing moisture, which can affect mesh tension over time. Steel frames are extremely durable and heavy-duty, making them suitable for industrial applications where strength is a priority, but they are less common due to their weight and cost.

When selecting a frame, consider the size of your prints and the type of printing press you’re using. Frames should be slightly larger than the design to allow for proper clamping and ink application. Additionally, ensure the frame is compatible with your mesh—some frames require specific mounting systems (e.g., adhesive, staples) to attach the mesh securely.

Conclusion: Invest in Quality for Exceptional Results

Emulsion, film sheets, mesh, and frames are the building blocks of successful screen printing. Each consumable plays a unique and vital role, and cutting corners on quality can lead to poor print results, wasted time, and increased costs. By understanding the functions and key considerations of each supply, you can make informed decisions that align with your printing needs—whether you’re a hobbyist creating custom t-shirts or a business producing high-volume promotional materials.

Remember, the best supplies are those that work together seamlessly. Choose emulsion, mesh, and film sheets that are compatible with each other and with your inks and substrates, and invest in durable frames that maintain consistent tension. With the right supplies and a little practice, you’ll be able to produce sharp, vibrant, and long-lasting screen prints every time.

Looking for high-quality screen printing supplies? Explore our range of emulsion, film sheets, mesh, and frames—designed to meet the needs of both beginners and professionals. Contact our team today for personalized recommendations!