In the competitive world of product packaging and branding, standing out from the crowd is more important than ever. Consumers are drawn to details that convey quality, sophistication, and value—and one material that delivers on all these fronts is hot stamping foil. Whether you’re a manufacturer, a brand owner, or a designer, understanding the benefits, applications, and selection tips of hot stamping foil can help you elevate your products to new heights. Let’s dive into everything you need to know about this versatile and luxurious material.

What is Hot Stamping Foil?

What is Hot Stamping Foil?

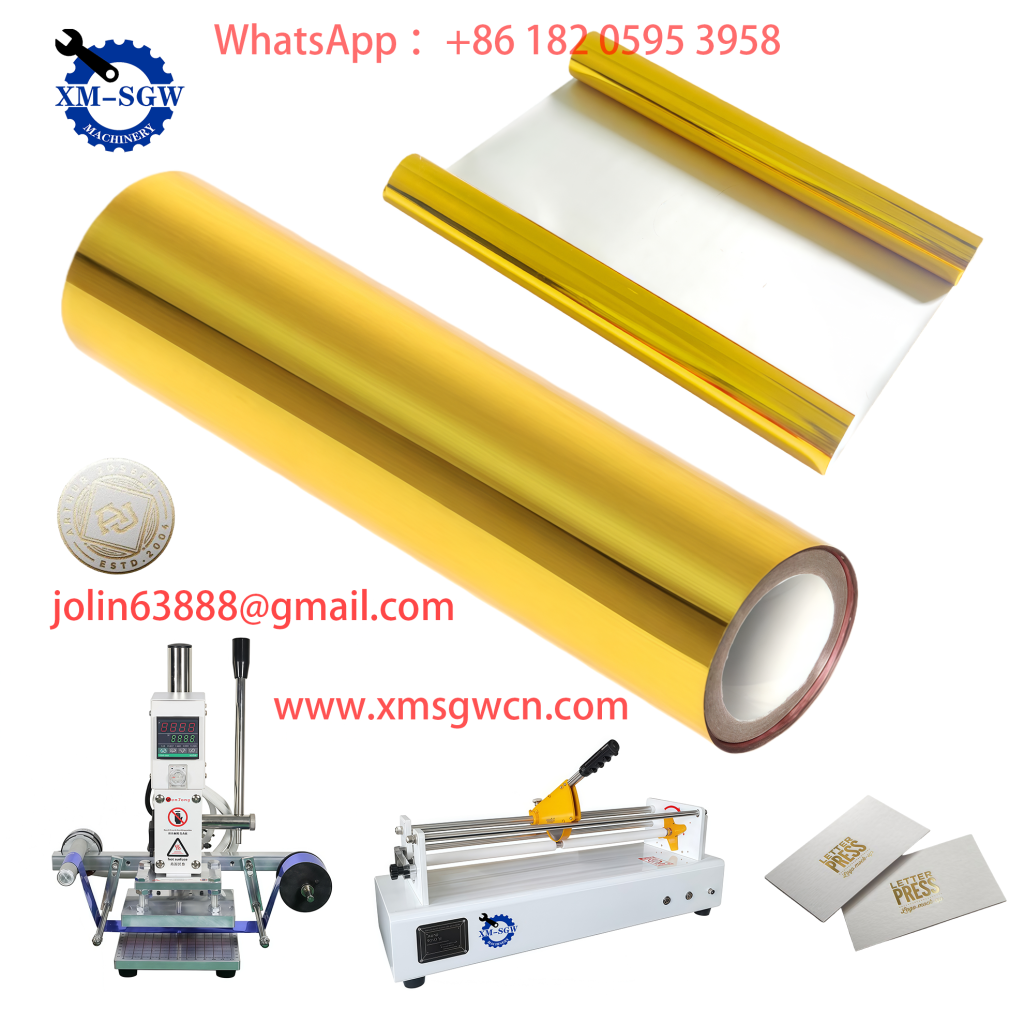

Hot stamping foil is a thin, multi-layered material used in the hot stamping process—a decorative technique that applies a metallic or colored finish to a variety of substrates. The foil itself typically consists of four key layers: a carrier film (usually polyester), a release layer (which allows the foil to separate from the carrier during stamping), a color or metallic layer (the visible decorative part), and an adhesive layer (that bonds the foil to the substrate).

The hot stamping process works by using a heated die to press the foil onto the target material. The heat activates the adhesive layer, and the pressure from the die transfers the color/metallic layer from the carrier film to the substrate, creating a crisp, permanent design. Unlike other decorative methods like printing, hot stamping foil creates a tactile, raised finish that adds depth and luxury to any product.

Key Benefits of Using Hot Stamping Foil

Key Benefits of Using Hot Stamping Foil

Hot stamping foil has become a popular choice for branding and decoration due to its unique advantages. Here are the top benefits that make it a worthwhile investment:

1. Luxurious Aesthetic Appeal

One of the most significant benefits of hot stamping foil is its ability to create a high-end, premium look. Metallic foils (such as gold, silver, copper, and rose gold) add a touch of elegance and sophistication, making products appear more valuable. Even non-metallic foils (like matte, glossy, or holographic finishes) can enhance the visual appeal of a product, helping it stand out on store shelves or in online listings.

2. Exceptional Durability

Unlike printed designs, which can fade, scratch, or smudge over time, hot stamped foil is highly durable. The bonded layer is resistant to water, abrasion, and UV rays, ensuring that the design remains intact even in harsh conditions. This durability makes hot stamping foil ideal for products that are handled frequently, exposed to the elements, or need a long shelf life (such as packaging, cosmetics, and electronics).

3. Versatility Across Substrates

Hot stamping foil can be applied to a wide range of materials, including paper, cardboard, plastic, leather, fabric, wood, and even metal. This versatility makes it suitable for various industries, from packaging and printing to fashion, automotive, and electronics. Whether you’re stamping a logo on a paper box, a leather bag, or a plastic electronic device, there’s a hot stamping foil designed for the job.

4. Precise and Crisp Details

Hot stamping technology allows for precise reproduction of fine details, intricate patterns, and small text. The heated die ensures that the foil is transferred evenly, creating sharp, clean lines that are difficult to achieve with other decorative methods. This precision is essential for branding, as it ensures that logos, slogans, and other brand elements are reproduced accurately and consistently.

5. Eco-Friendly Options

As sustainability becomes a top priority for brands and consumers, many hot stamping foil manufacturers now offer eco-friendly options. These foils are made from recycled materials, use water-based adhesives, or are fully recyclable, allowing brands to enhance their products’ appeal without compromising their environmental values.

Common Applications of Hot Stamping Foil

Common Applications of Hot Stamping Foil

Hot stamping foil is used in a wide range of industries and applications. Here are some of the most common uses:

1. Packaging Industry

Packaging is one of the largest markets for hot stamping foil. It’s used to decorate boxes (for cosmetics, perfumes, wine, chocolates, and luxury goods), bags (paper and plastic), labels, and tags. The metallic or decorative finish helps packaging stand out, attract consumers, and convey the product’s premium quality.

2. Printing and Publishing

In the printing industry, hot stamping foil is used to enhance books (covers, spines, and dust jackets), magazines, brochures, business cards, and invitations. It adds a touch of luxury to printed materials, making them more memorable and professional.

3. Fashion and Accessories

Hot stamping foil is widely used in the fashion industry to decorate leather goods (bags, wallets, shoes, and belts), fabric (clothing, scarves, and hats), and accessories (jewelry boxes, watch bands, and sunglasses). It’s an effective way to add logos, patterns, or decorative elements to fashion items, enhancing their brand identity and aesthetic appeal.

4. Electronics and Appliances

Electronics manufacturers use hot stamping foil to decorate device casings (smartphones, laptops, and tablets), remote controls, and appliance panels. The durable finish resists scratches and wear, ensuring that the brand logo and other details remain visible for the life of the product.

5. Automotive Industry

In the automotive sector, hot stamping foil is used to decorate interior components such as dashboards, steering wheels, door panels, and gear shifts. It adds a premium look to the vehicle’s interior, enhancing the overall driving experience.

How to Choose the Right Hot Stamping Foil

How to Choose the Right Hot Stamping Foil

Choosing the right hot stamping foil for your project depends on several factors. Here are some key considerations to keep in mind:

1. Substrate Material

The first and most important factor is the substrate you’ll be stamping. Different foils are formulated to bond with different materials. For example, foils designed for paper may not work well with plastic, and vice versa. Be sure to select a foil that is compatible with your substrate (e.g., paper, plastic, leather, etc.).

2. Desired Finish

Next, consider the finish you want to achieve. Do you need a metallic finish (gold, silver, etc.), a matte finish, a glossy finish, or a holographic finish? Metallic foils are ideal for luxury products, while matte foils offer a more understated, sophisticated look. Holographic foils add a unique, eye-catching effect that’s perfect for promotional items.

3. Durability Requirements

Consider the environment your product will be exposed to. If the product will be handled frequently, exposed to water, or used outdoors, you’ll need a foil with high durability (e.g., UV-resistant, water-resistant, and scratch-resistant). For indoor products with minimal handling, a standard foil may be sufficient.

4. Stamping Process Parameters

The hot stamping process requires specific temperature, pressure, and speed settings. Different foils have different temperature and pressure requirements, so be sure to select a foil that is compatible with your stamping equipment and process parameters. Consult the foil manufacturer’s guidelines for recommended settings.

5. Sustainability Goals

If sustainability is a priority for your brand, look for eco-friendly hot stamping foils. These foils may be made from recycled materials, use non-toxic adhesives, or be fully recyclable. Be sure to ask the manufacturer about their sustainability credentials.

Tips for Successful Hot Stamping

Tips for Successful Hot Stamping

To ensure the best results with hot stamping foil, follow these tips:

- Test first: Always perform a test run on a sample of your substrate before stamping large quantities. This will help you adjust the temperature, pressure, and speed settings for optimal results.

- Use the right die: The die should be made from high-quality material (e.g., brass or steel) and be properly engraved to ensure crisp, clean details. A worn or poorly engraved die will result in a subpar finish.

- Keep the foil clean: Dust, dirt, or oil on the foil can affect the transfer process. Store the foil in a clean, dry environment and handle it with clean hands.

- Maintain consistent temperature: Fluctuations in temperature can cause the foil to transfer unevenly. Ensure that your stamping equipment maintains a consistent temperature throughout the process.

- Work with a reputable supplier: Choose a hot stamping foil supplier with a proven track record of quality and reliability. They can provide expert advice on selecting the right foil for your project and troubleshooting any issues that arise.

Conclusion

Conclusion

Hot stamping foil is a versatile, durable, and luxurious material that can elevate the look and feel of any product. Whether you’re looking to enhance your packaging, brand your fashion items, or decorate electronic devices, hot stamping foil offers a range of benefits that make it a smart investment. By understanding the key factors to consider when choosing a foil, following best practices for hot stamping, and working with a reputable supplier, you can achieve professional, eye-catching results that help your products stand out in the market.

Ready to take your products to the next level with hot stamping foil? Explore our range of high-quality hot stamping foils today, or contact our team of experts to find the perfect solution for your project.