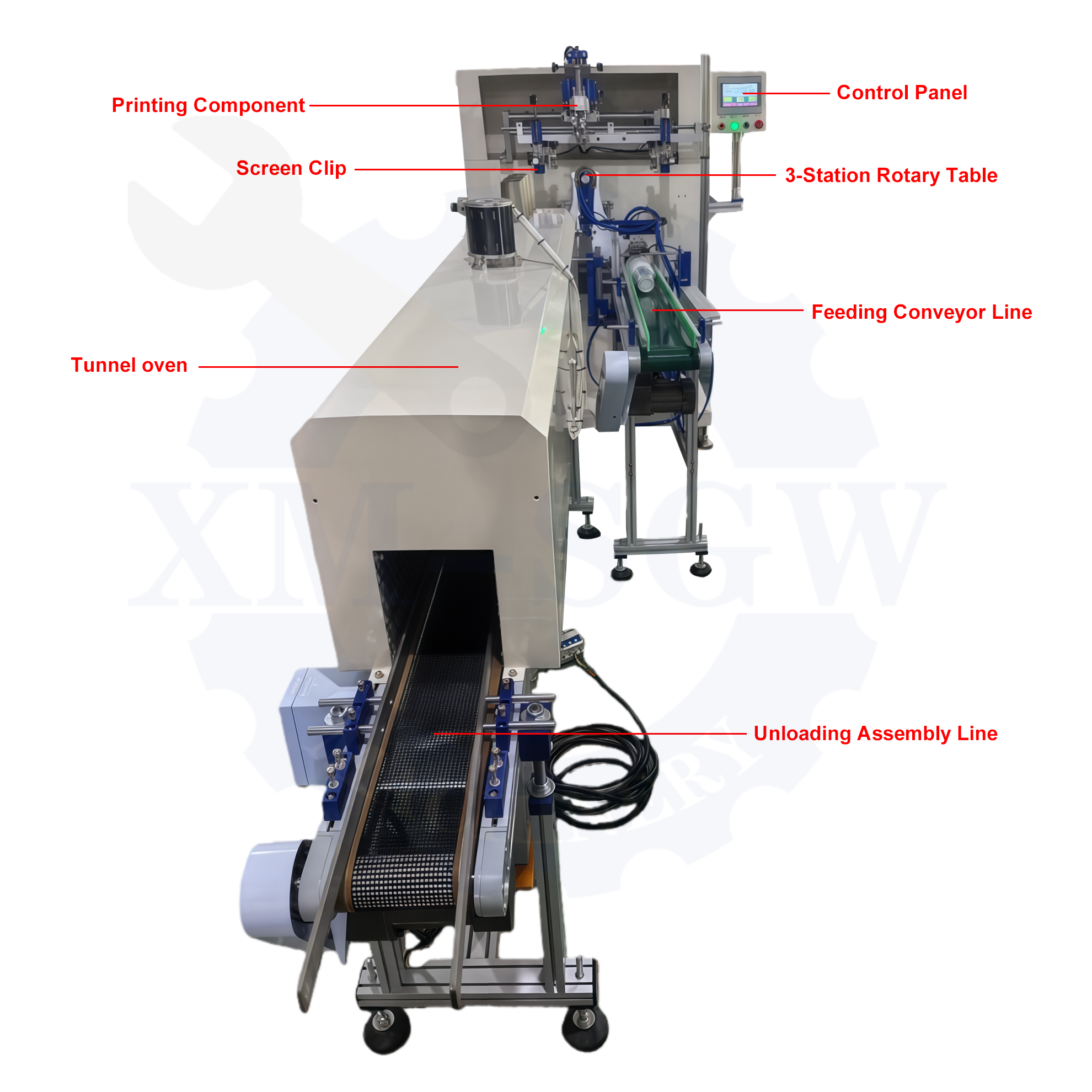

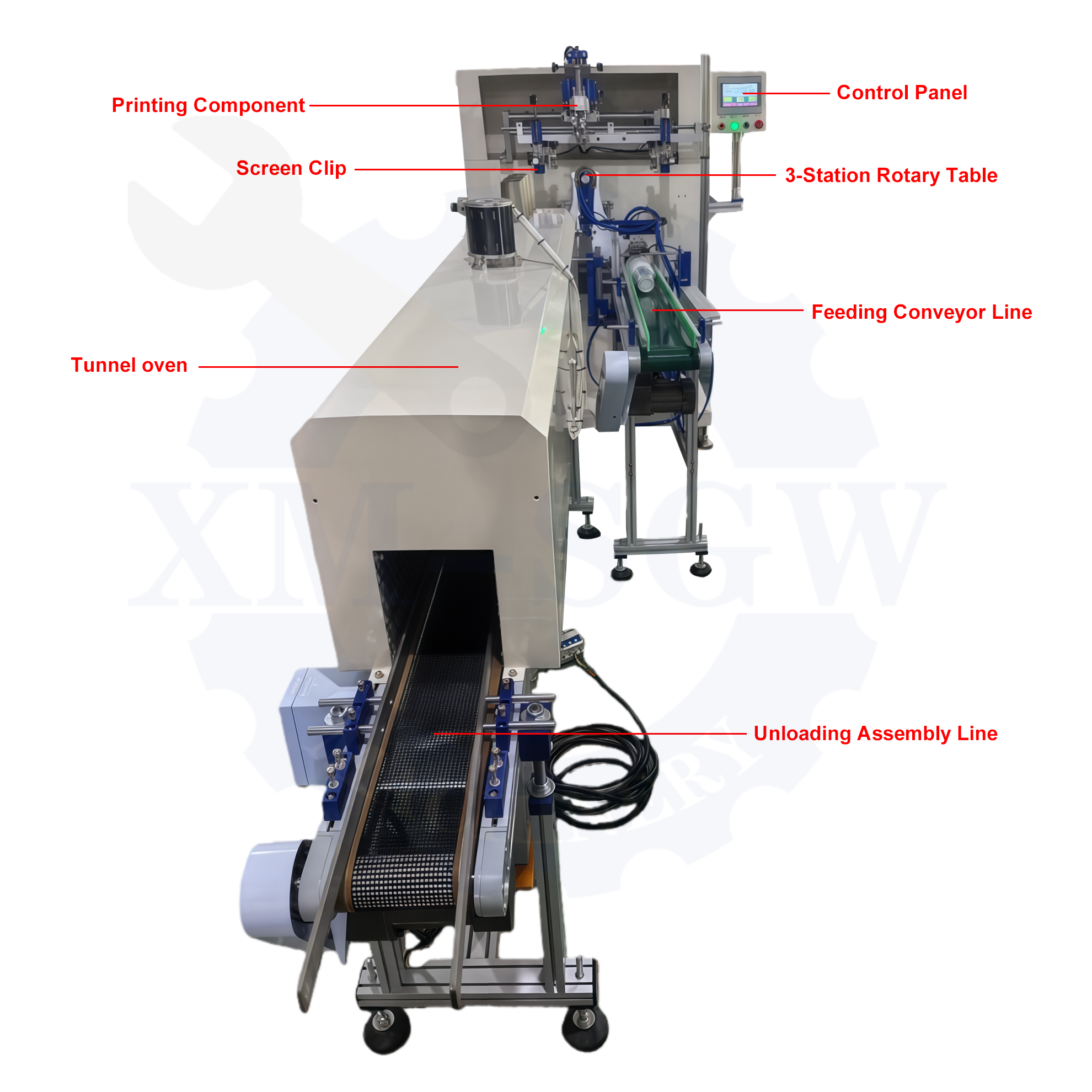

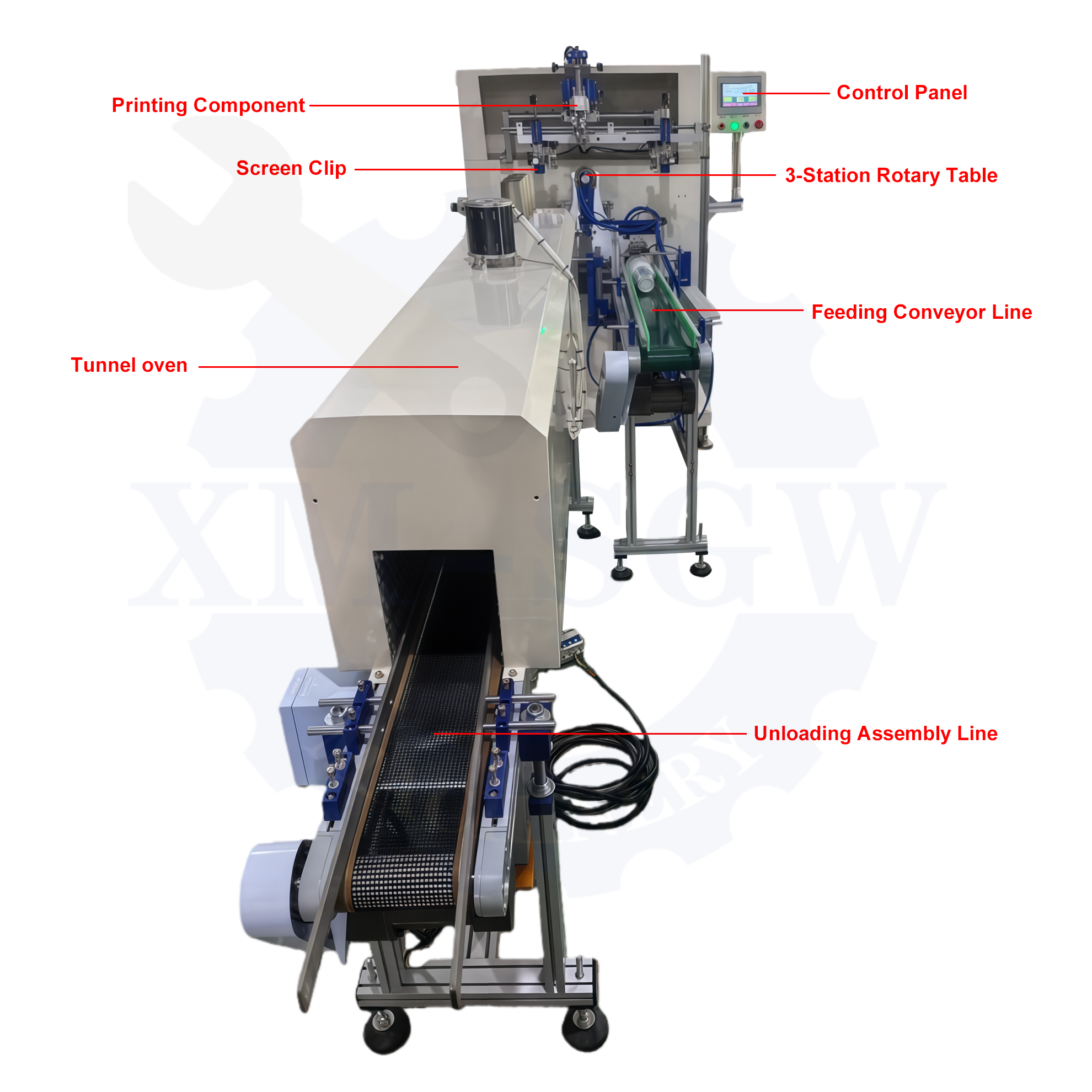

3 Station Fully Automatic Single Color Cup Screen Printing Machine Inline Tunnel Drying All in One Machine

-

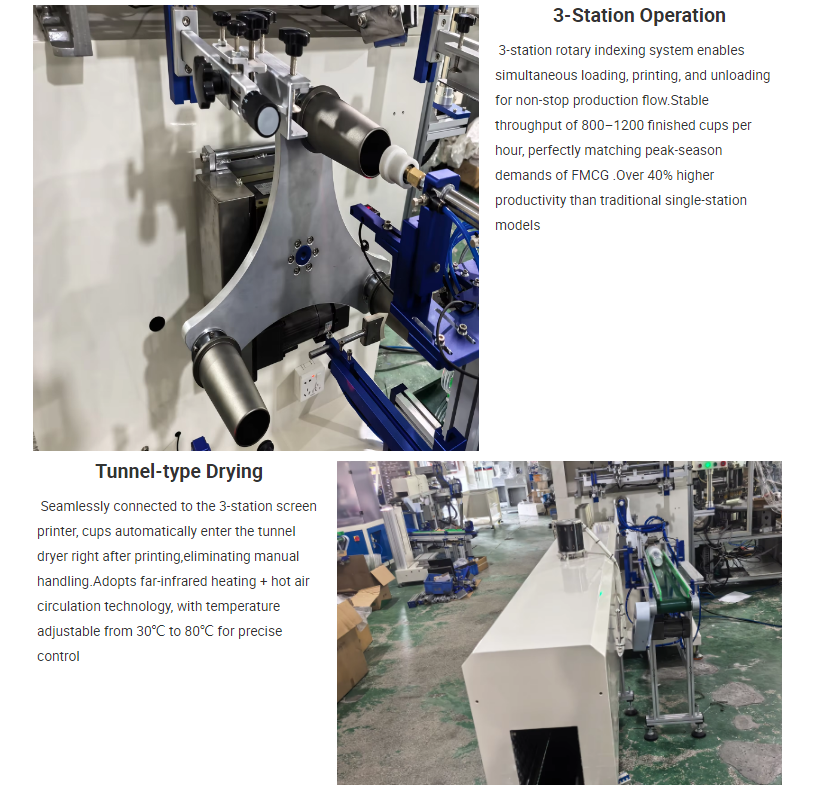

Three-Station Synchronous Operation: Feeding, printing and discharging work simultaneously for continuous production, shortening cycles and avoiding idleness.

-

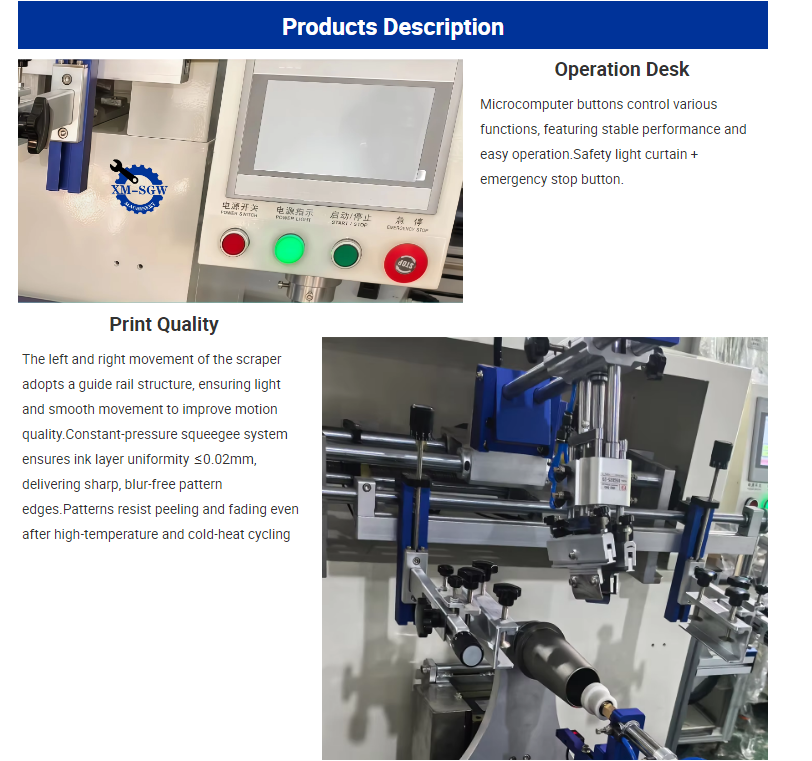

High-Precision Printing: Equipped with precision guide rail and positioning system, printing accuracy up to ±0.1mm, with uniform ink and clear patterns.

-

Sturdy & Durable: Made of high-quality aluminum alloy and steel, treated with anti-rust processes, stable and vibration-reducing for long service life.

-

User-Friendly: Simple PLC control and touch screen, easy to set parameters, no professional skills required, saving training costs.

-

Wide Compatibility: Suitable for flat workpieces of plastic, metal, glass, etc., matching different screens to meet diverse needs.

-

Adjustable Parameters: Stepless adjustment of scraper pressure, speed and stroke for consistent printing effect.

-

Safe Design: With safety cover and emergency stop button, complying with international safety standards.

3 Station Fully Automatic Single Color Cup Screen Printing Machine Description

Cup Screen Printing Machine Data Sheet

Cup Screen Printing Machine Applications

1. Central Kitchen Production for Chain Milk Tea & Coffee Brands

* Ideal for large-scale, unified printing of branded milk tea/coffee cups for regional or national chain catering brands.

* The integrated 3-station printing + tunnel drying workflow ensures consistent print quality across thousands of cups,supporting peak-season demand for new product launches or promotional campaigns.

* Food safety compliance (GB 4806.9) meets the strict hygiene standards of chain catering central kitchens.

2.Disposable Packaging Contract Manufacturing

* Perfect for packaging factories that serve multiple FMCG clients, enabling quick switching between different cup sizes, logos,and single-color designs.

* The 15-minute quick changeover and high throughput (800–1200 cups/hour) efficiently handle mixed small-to-medium batch orders, reducing idle time between jobs.

* The tunnel dryer eliminates post-printing manual handling, cutting labor costs and lowering defect rates for contract manufacturers.

3.E-Commerce Custom Cup Order Fulfillment

* Tailored for small-batch, high-mix custom cup orders from e-commerce platforms (e.g., branded cups for small cafes, event giveaways, or personalized gifts).

* The 3-station design and quick plate-changing mechanism allow rapid pattern switching, ensuring fast delivery of custom printed cups with precise logo/text reproduction.

4.Catering Exhibition & Promotional Material Production

* Ideal for short-turnaround production of promotional cups for food expos, seasonal marketing campaigns, or limited-time offers.

* The all-in-one printing + drying system delivers fully cured, smudge-free cups in hours, supporting urgent promotional deadlines.

* Enables printing of QR codes, discount information, or event logos to drive customer engagement.

5. Cold Beverage & Ice Cream Brand Cup Production

* Optimized for printing on PP/PET cups used for iced drinks, smoothies, and ice cream, where ink adhesion and resistance to cold-heat cycling are critical.

* The far-infrared tunnel dryer ensures deep ink curing, preventing pattern peeling or fading when cups are filled with cold beverages or stored in freezers.

* Food-grade ink compatibility meets safety standards for direct food contact packaging.

6.Large-Scale Food Packaging Production

* Suitable for manufacturers producing disposable cups for food packaging (e.g., yogurt cups, dessert cups) that require single-color branding or nutritional information printing.

* The heavy-duty industrial structure and low monthly failure rate (<2%) support 24/7 continuous production for high-volume food packaging orders.

Get Free Quote of 3 Station Fully Automatic Single Color Cup Screen Printing Machine

Related News

For packaging factories and F&B brand buyers, delivering consistent, high-quality printed cups on time isn’t just a goal—it’s a make-or-break […]

In the fast-paced world of electronics manufacturing, Printed Circuit Boards (PCBs) serve as the backbone of nearly every electronic device—from […]

In a world where brand visibility matters more than ever, custom-printed bags have become a powerful marketing tool. From retail […]

In screen printing, even the most high-quality mesh, ink, and stencil can fall short if your substrate isn’t held securely. […]

In the world of screen printing, every detail matters. From ink selection to machine calibration, each element plays […]

Screen printing (also known as silk screening) is a versatile printing technique that brings designs to life on nearly any […]