CE Certified Tunnel Type Infrared Dryer Durable Industrial Drying Tool

- Fast drying speed, cuts production cycle significantly

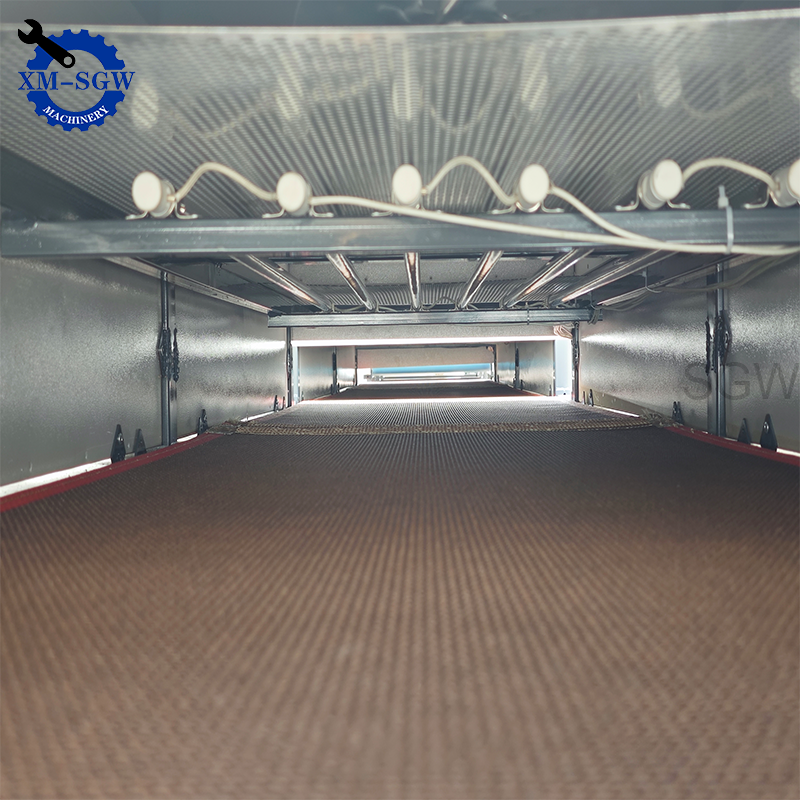

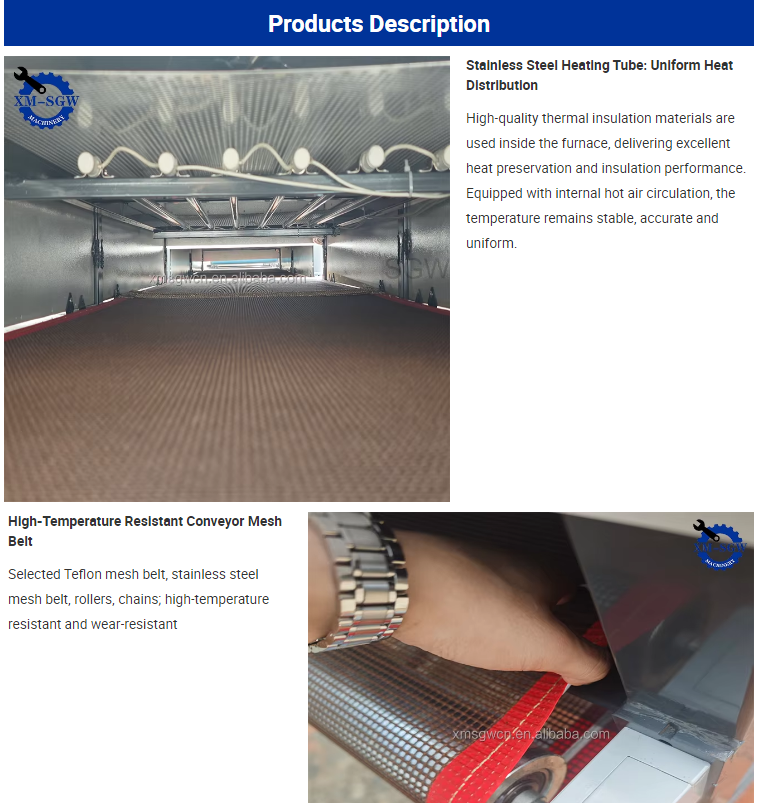

- Uniform heat distribution, prevents local overheating or incomplete drying

- Energy-efficient, lower power consumption than traditional drying equipment

- Versatile application (screen printing, electronics, coating, etc.), ideal for ink curing

- Easy operation and maintenance, reduces long-term operational costs

- Targeted infrared heating with strong penetration

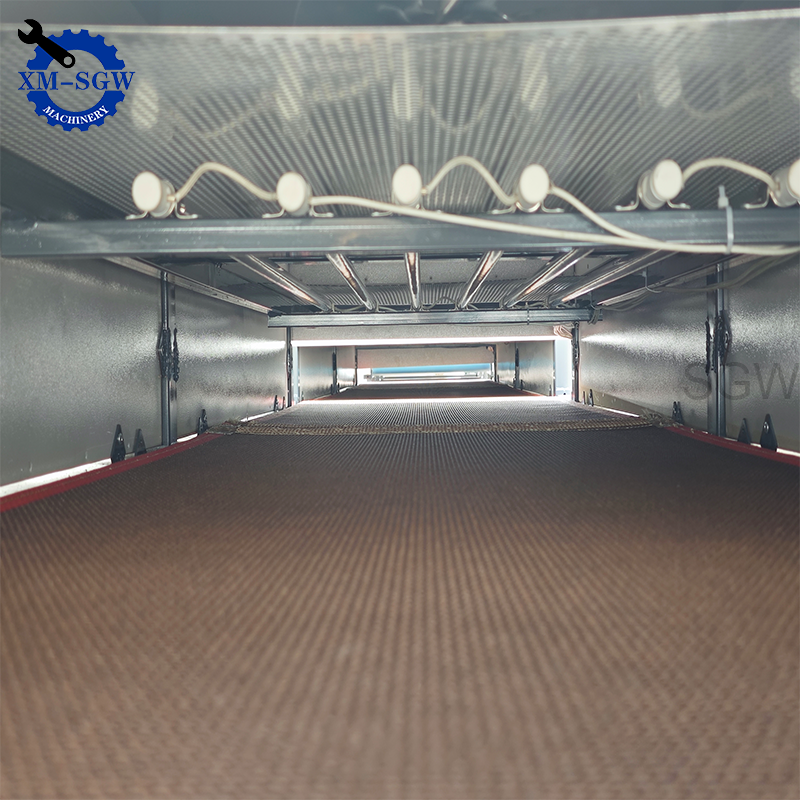

- Continuous tunnel conveyor design for assembly line integration

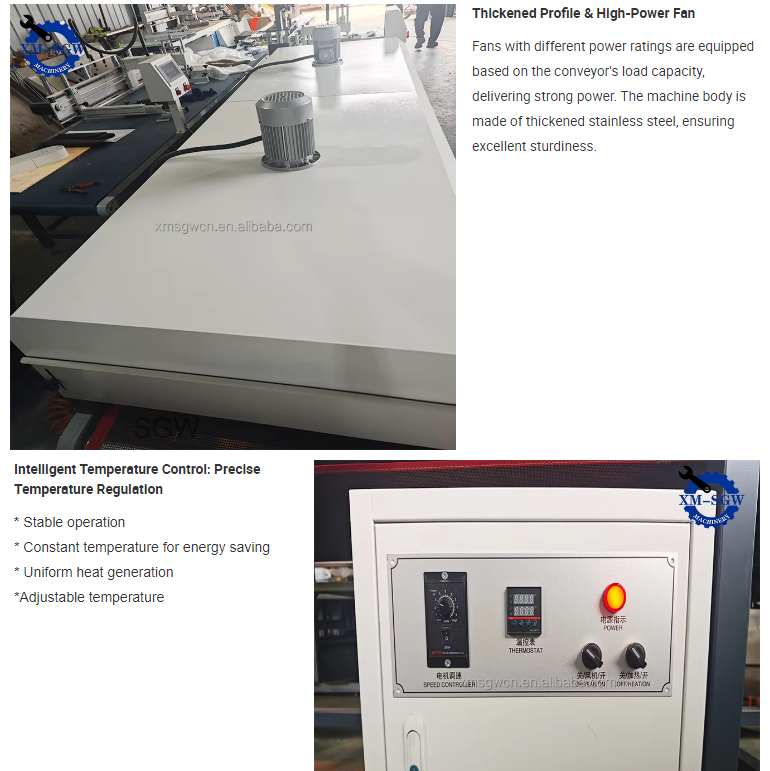

- Intelligent precise temperature control system with adjustable range

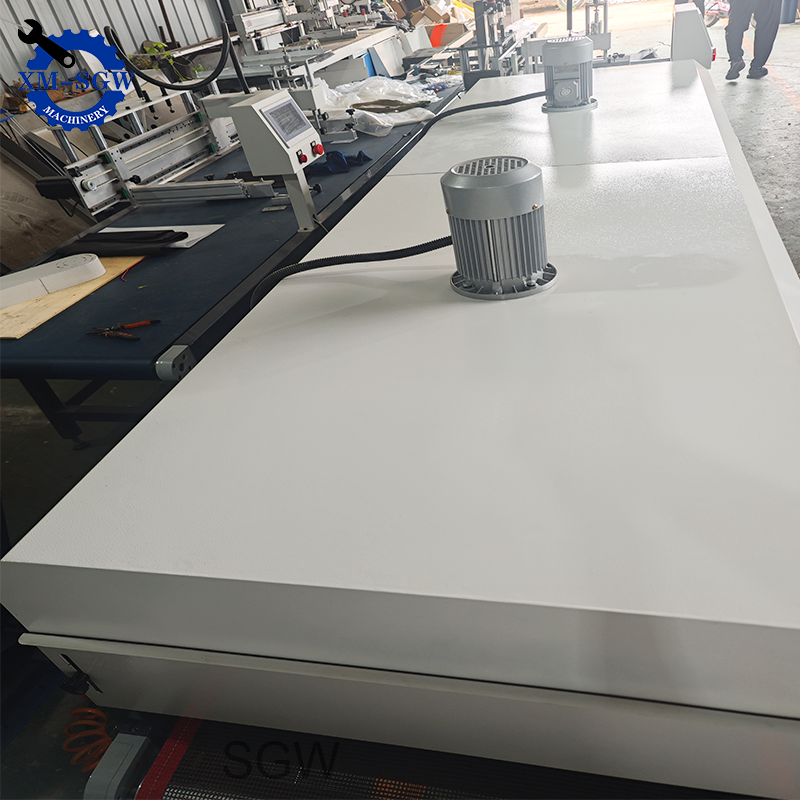

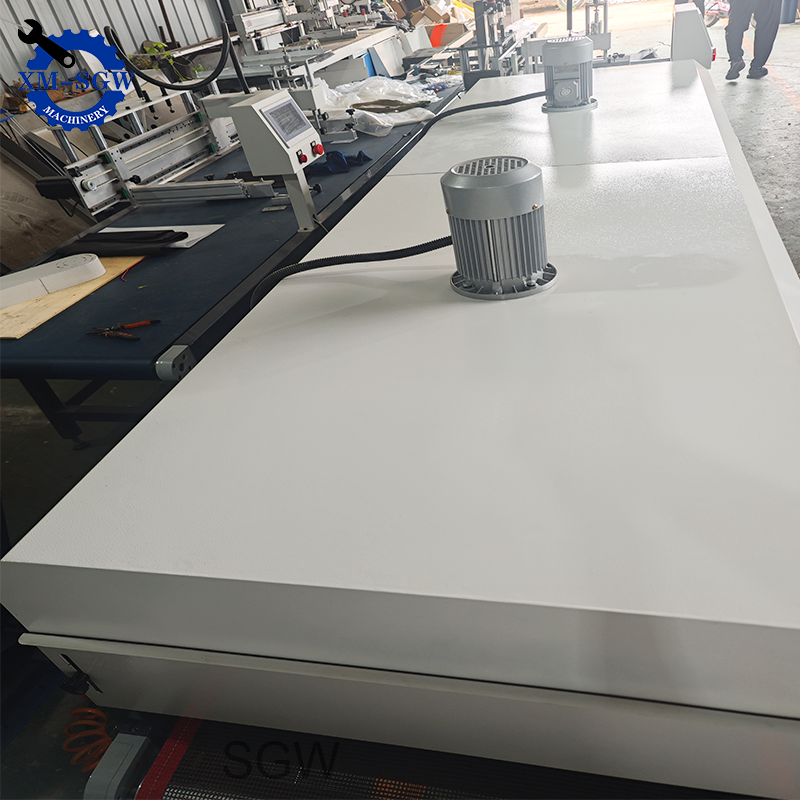

- Compact structure, space-saving for workshop layout

- Durable stainless steel construction, corrosion-resistant

Products Categories

Get A Free Quote

Tunnel Type Infrared Dryer Description

Tunnel Type Infrared Dryer Detail Display

Tunnel Type Infrared Dryer Data Sheet

Tunnel Type Infrared Dryer Applications

- Screen Printing: Rapid ink curing for textiles, plastics, paper and metal substrates, ensuring no damage to materials.

- Electronics: Drying and curing PCBs, capacitors and sensors with precise temperature control to protect heat-sensitive components.

- Coating & Painting: Uniform curing of metal, plastic and wood surface coatings, enhancing adhesion and avoiding defects.

- Packaging Printing: Quick drying of ink and glue on flexible films, cartons and paper cups to prevent smudging.

- Textiles: Fabric drying and shaping after dyeing, maintaining color fastness and shape stability.

Tunnel Type Infrared Dryer Video

Get Free Quote of Tunnel Type Infrared Dryer

Related News

Tunnel Type Infrared Dryer: The Efficient, Energy-Saving Solution for Industrial Drying In the realm of industrial manufacturing and processing, […]

In today’s fast-paced manufacturing landscape—where speed, sustainability, and precision are non-negotiable—UV curing machines have emerged as a game-changer. Unlike traditional […]