SGW High Quality Flat Screen Printing Machine for Remote Control Keyboard Silicone Pad

1. Compile action programs using integrated circuits

2. An automatic four-digit counter for counting print quantities; The body is made of all-cast aluminum and the surface is powder-coated and baked.

3. The screen lifting adopts a structure driven by a Taiwan motor and linear guide rails, which is stable and highly accurate.

4. The left and right travel is adjustable, and it is limited by Taiwan photoelectric switches.

5. The Angle of the scraper/ink return knife can be adjusted freely.

6. Fine-tune the rotation Angle of the workbench to the right front and back, left and right, and then lock it.

7. The position of the mesh frame can be adjusted horizontally up and down. 8. Stainless steel suction platform.

Flat Keyboard Silicone Pad Screen Printing Machine Description

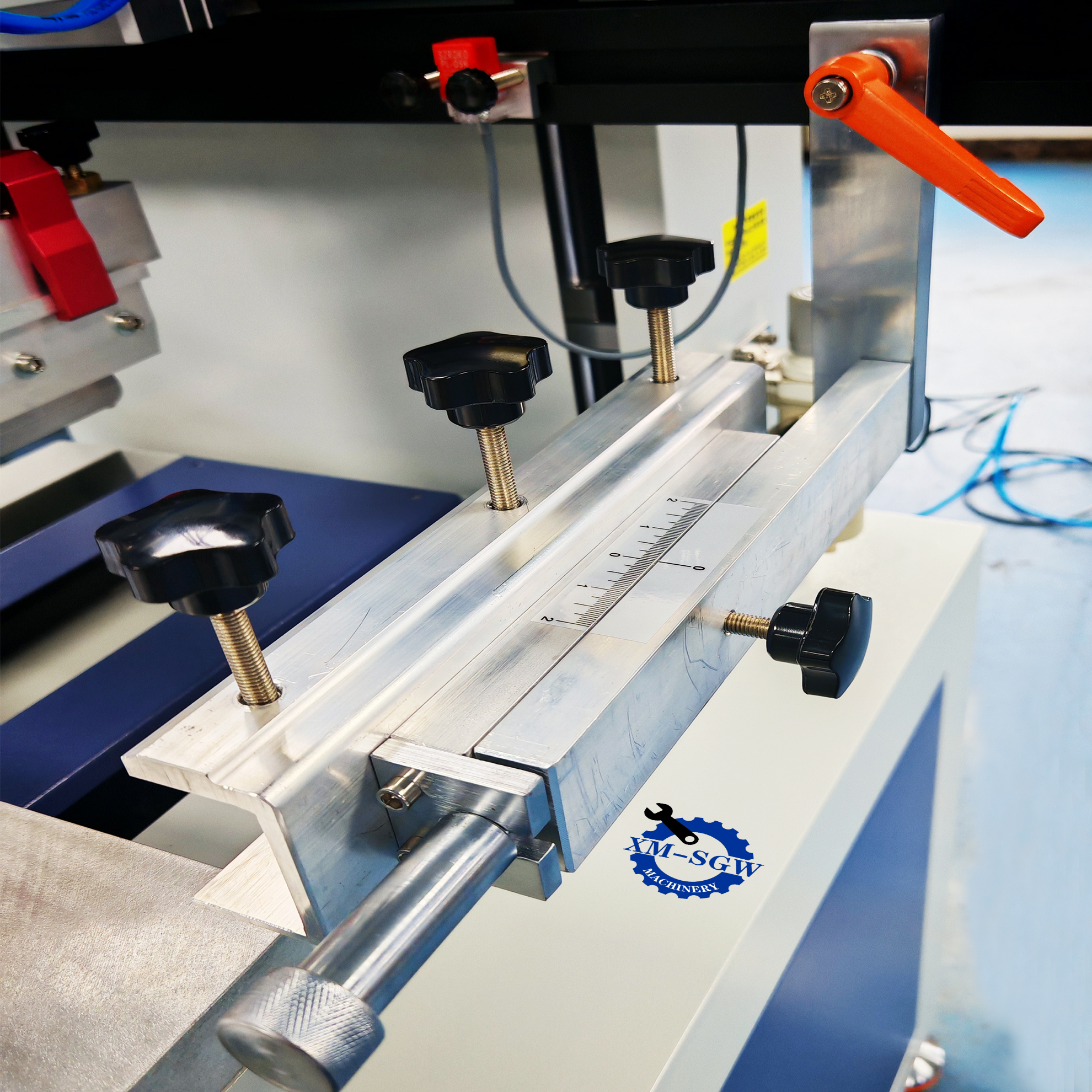

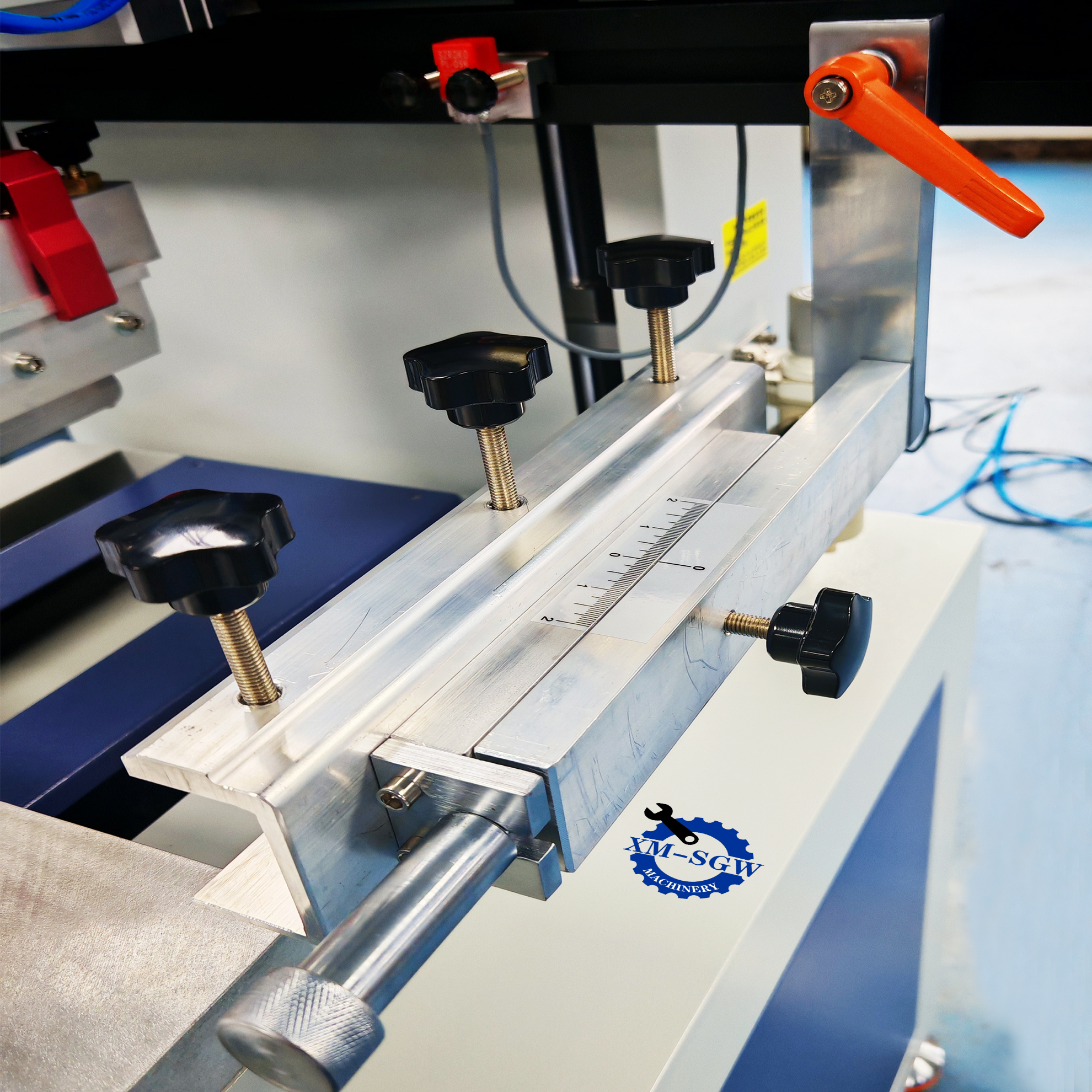

* Enable flexible adjustment (via the knobs) to adapt to different sizes of screen frames or printing materials.

* Maintain the stability of the print head, ensuring precise ink transfer and consistent print quality.

marked scale.

* Help operators calibrate the machine to match different printing materials or screen specifications.

* Maintain consistent operational accuracy, which supports stable print quality.

substrates of different sizes.

* Lock the adjusted position with the knobs, ensuring the station stays stable during printing (to avoid offset that harms print accuracy).

* Work with other machine parts to quickly calibrate the printing station, boosting efficiency when changing materials or screen plates.

* Filter out impurities (dust, moisture) from the compressed air, protecting downstream pneumatic parts from wear or blockage to extend their service life.

* Display the current working pressure in real-time via the built-in gauge, enabling operators to monitor and fine-tune pressure quickly.

Flat Screen Printing Machine Data Sheet

|

Plate size

|

500*700mm

|

|

Maximum printing area

|

450*600mm

|

|

Maximum mesh frame size

|

600*950mm

|

|

Two-way adjustment size of the tabletop

|

±10mm

|

|

Adjustment angle of the scrape

|

0-45°

|

|

Maximum printing height

|

0-250mm

|

|

Printing speed

|

800 units/hour

|

|

Power supply

|

220V 50-60MHZ | 300W

|

Flat Screen Printing Machine Applications

Get Free Quote of Silicone Pad Flat Screen Printing Machine

Related News

Screen printing is a versatile and widely used printing technique, favored by businesses and hobbyists alike for its ability to […]

In a world where brand visibility matters more than ever, custom-printed bags have become a powerful marketing tool. From retail […]