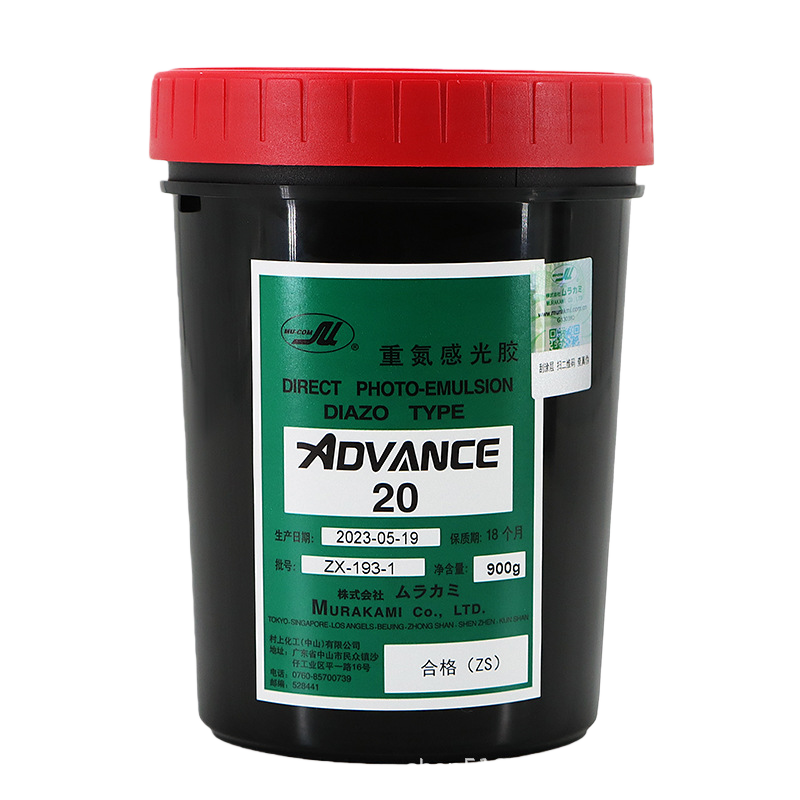

SGW Most Popular Water and Solvent Resistance Photo Emulsion for Silk Screen Printing

1. Ultra-high Resolution & Sharp Edges

Delivers crisp, precise stencil details down to 0.1mm line width, ideal for fine-line circuit boards, intricate logos and high-end packaging printing.

2. Fast & Uniform Exposure

Rapid curing speed (15-30s under UV light) with even light absorption, reducing production time and boosting batch consistency.

3. Strong Adhesion & Durability

Excellent bonding to polyester and stainless steel mesh; resists water, solvents and scraping during repeated printing (up to 10,000+ impressions per stencil).

Washes out quickly with tap water; fully removable with emulsion remover without leaving residues, enabling mesh reuse and cost savings.

Works perfectly with solvent-based, water-based and UV inks; suitable for screen printing on glass, plastic, metal, fabric and paper substrates.

12-month shelf life in sealed containers (stored at 5-25℃); maintains consistent sensitivity and viscosity without stratification.

7. Eco-friendly Formula

Low VOC content, non-toxic and odorless; compliant with RoHS and REACH standards, safe for operators and the environment.

Photo Emulsion for Silk Screen Printing Description

Step 1

Step 2

Step 3

Step 4

Photo Emulsion for Silk Screen Printing Data Sheet

The photosensitive emulsion must be stored and used within a temperature range of 18-25℃. Storage below 0℃ is prohibited. Instructions for Use:

1. The photosensitive emulsion must be properly prepared and stirred evenly;

2. The screen must be thoroughly cleaned;

3. It must be completely dried during the drying process;

4. Exposure time: 35-45 seconds. If the exposure effect is not satisfactory, extend the time by 10-15 seconds;

5. For increased durability, two exposures are recommended.

The photosensitive emulsion is the basic material for forming images on screen printing plates. It combines with the screen, and after exposure, development, rinsing, drying, screen sealing, and retouching, it forms the screen printing plate.

Photo Emulsion for Silk Screen Printing Applications

1. Electronic & Circuit Printing

Stencil making for PCB (Printed Circuit Boards), FPC (Flexible Printed Circuits), solar cell electrodes, and electronic

component markings.

2. Packaging & Label Printing

Ideal for food packaging (plastic films, paper bags), beverage labels, cosmetic containers, and anti-counterfeiting label

stencils.

3. Textile & Garment Printing

Screen stencils for cotton, polyester, and blended fabrics (t-shirts, hoodies, sportswear) with water-based or solvent-

Custom designs for glass bottles, jars, ceramic tiles, tableware, and decorative glass panels (home decor, building

materials).

5. Metal & Plastic Printing

Marking and branding on metal parts (automotive components, hardware), plastic products (toys, electronic casings,

Large-format screen printing for billboards, posters, acrylic signs, and LED display panels.

7. Specialty & Industrial Printing

Stencils for battery casings, semiconductor wafers, leather goods, and precision instrument markings.

Get Free Quote of Photo Emulsion for Silk Screen Printing

Related Products

Related News

Screen printing is a versatile and widely used printing technique, favored by businesses and hobbyists alike for its ability to […]

In the world of screen printing, every detail matters. From ink selection to machine calibration, each element plays […]