In manufacturing and processing industries, the hot press machine stands as a pivotal piece of equipment, enabling the bonding, shaping, and curing of materials through controlled heat and pressure. From woodworking to composite materials, electronics to textiles, its versatility makes it indispensable for businesses aiming to achieve consistent, high-quality results. This guide breaks down everything you need to know about hot press machines—how they work, their key applications, factors to consider when buying one, and tips for long-term maintenance.

1. How Does a Hot Press Machine Work?

At its core, a hot press machine operates on the principle of applying regulated heat and uniform pressure to a workpiece over a set period. The process typically involves three key components:

- Heating System: Equipped with heating plates (usually made of aluminum or steel for efficient heat transfer), the system heats up to a preset temperature (ranging from 50°C to 400°C, depending on the material). Some advanced models use infrared heating or oil circulation for faster, more even heat distribution.

- Pressure System: Driven by hydraulic cylinders, pneumatic systems, or electric motors, this component applies pressure (measured in psi or bar) to the workpiece. Hydraulic systems are ideal for heavy-duty tasks requiring high pressure, while pneumatic options suit lighter applications.

- Control Panel: A digital interface allows operators to adjust temperature, pressure, and pressing time—critical for matching the machine’s settings to the material’s requirements (e.g., lower heat for delicate fabrics, higher pressure for wood veneering).

Once the settings are locked in, the workpiece (e.g., two wood panels with adhesive, a composite laminate) is placed between the heating plates. The machine then closes the plates, applies heat and pressure, and holds the settings for the specified duration. After pressing, the plates retract, and the finished product is removed—bonded, shaped, or cured to meet industry standards.

2. Key Applications of Hot Press Machines

Hot press machines are used across a wide range of industries, thanks to their ability to handle diverse materials. Here are the most common use cases:

a. Woodworking & Furniture Manufacturing

In woodworking, hot presses are essential for:

- Bonding plywood, MDF (medium-density fiberboard), and particleboard with veneers or laminates.

- Pressing solid wood panels to remove warping or shape them into curved designs.

- Curing wood adhesives (e.g., urea-formaldehyde, polyurethane) quickly, ensuring strong, durable joints.

b. Composite Materials Production

For industries working with composites (e.g., carbon fiber, fiberglass, or plastic composites), hot presses facilitate:

- Curing composite laminates to create lightweight, high-strength parts for aerospace, automotive, or sports equipment (e.g., bike frames, aircraft components).

- Bonding composite layers with resins, ensuring no air bubbles or gaps in the final product.

c. Electronics & PCB Manufacturing

In electronics, precision is key—hot presses are used for:

- Soldering components onto PCBs (printed circuit boards) with controlled heat to avoid damaging sensitive parts.

- Laminating flexible PCBs or bonding heat-sensitive electronic materials (e.g., insulation films).

d. Textiles & Apparel

Textile manufacturers rely on hot presses for:

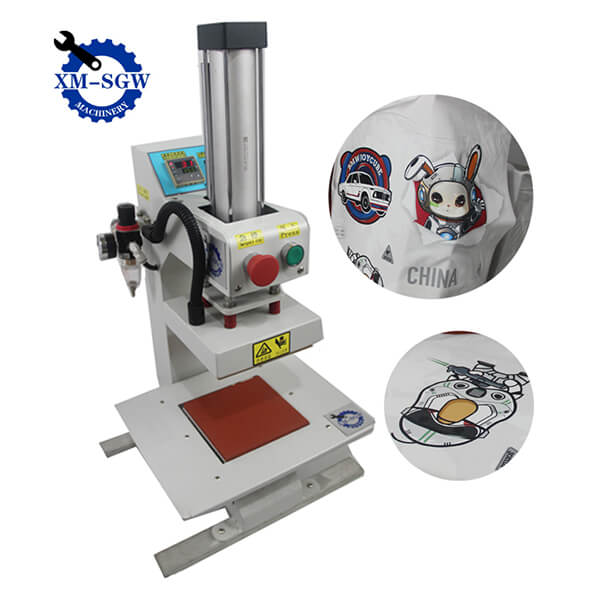

- Heat-transfer printing (applying designs to fabrics using heat and pressure).

- Bonding fabric layers (e.g., attaching interfacing to clothing for structure) or curing textile coatings (e.g., water-resistant finishes).

3. Factors to Consider When Choosing a Hot Press Machine

Not all hot press machines are created equal—selecting the right one depends on your specific needs. Here are the critical factors to evaluate:

a. Material & Application

- Material Type: Consider the material you’ll be working with (wood, composite, fabric, etc.). For example, a machine designed for wood veneering may not have the temperature range needed for composite curing.

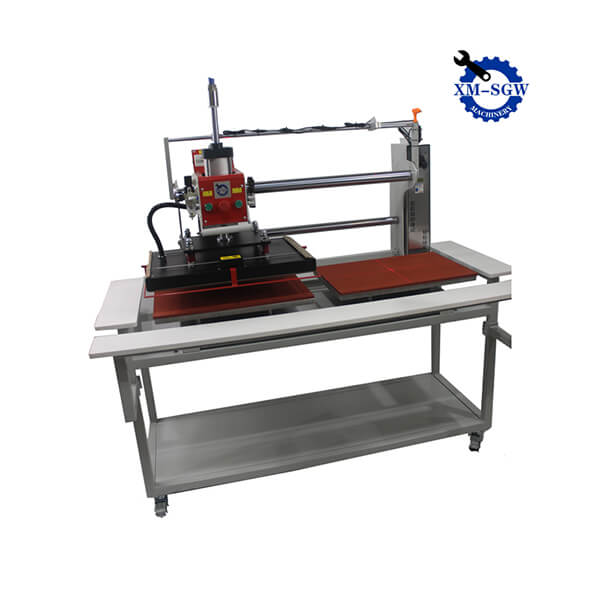

- Workpiece Size: Choose a machine with heating plates that match or slightly exceed the size of your typical workpiece. A machine with 600x900mm plates works for small to medium wood panels, while industrial-scale operations may need 1200x2400mm or larger.

b. Pressure & Temperature Range

- Pressure Capacity: For heavy-duty tasks (e.g., thick composite laminates), opt for a hydraulic machine with 50-200 bar pressure. Lighter tasks (e.g., textile printing) can use pneumatic machines with 5-50 bar pressure.

- Temperature Range: Ensure the machine’s maximum temperature covers your material’s requirements. For example, wood adhesives typically need 100-150°C, while carbon fiber composites may require 180-250°C.

c. Automation Level

- Manual/ Semi-Automatic: Suitable for small-batch production. Operators load/unload workpieces, and the machine controls heat/pressure.

- Fully Automatic: Ideal for high-volume manufacturing. Equipped with conveyors for loading/unloading, and PLC (Programmable Logic Controller) systems for presetting cycles—reducing labor and improving consistency.

d. Energy Efficiency & Safety

- Energy Efficiency: Look for machines with insulation on heating plates (to minimize heat loss) or energy-saving modes (e.g., automatic temperature reduction when idle) to lower operational costs.

- Safety Features: Essential features include emergency stop buttons, heat-resistant guards, and pressure relief valves to prevent accidents.

4. Maintenance Tips for Long-Lasting Performance

A well-maintained hot press machine can serve your business for years. Follow these tips:

- Daily Checks: Inspect heating plates for damage (e.g., scratches, warping) and clean them with a non-abrasive cloth to remove adhesive residue. Check hydraulic/pneumatic hoses for leaks.

- Weekly Maintenance: Lubricate moving parts (e.g., hinges, cylinders) to reduce friction. Calibrate temperature and pressure gauges using a professional tool to ensure accuracy.

- Monthly Servicing: Drain and replace hydraulic oil (if using a hydraulic system) to prevent contamination. Inspect electrical connections for loose wires or corrosion.

- Annual Overhaul: Hire a technician to disassemble key components (e.g., heating elements, pressure cylinders) for deep cleaning and replacement of worn parts (e.g., seals, gaskets).

5. Common FAQs About Hot Press Machines

Q1: Can a hot press machine be customized for specific tasks?

Yes, most manufacturers offer customization—e.g., adjusting plate size, adding extra heating zones, or integrating specialized controls for unique materials (e.g., heat-sensitive films).

Q2: What is the typical lifespan of a hot press machine?

With proper maintenance, a industrial-grade hot press machine can last 10-15 years. Smaller, semi-automatic models may last 5-8 years.

Q3: How much space does a hot press machine require?

Space varies by size: compact tabletop models (for small tasks) take up 1-2 sq. meters, while large industrial machines may need 5-10 sq. meters (including space for loading/unloading).

Final Thoughts

Investing in the right hot press machine can streamline your production process, improve product quality, and boost efficiency. By understanding your material needs, evaluating key features (pressure, temperature, automation), and following a regular maintenance schedule, you can ensure your machine delivers consistent results for years to come. Whether you’re a small woodworking shop or a large-scale composite manufacturer, a well-chosen hot press machine is a cornerstone of success in modern manufacturing.

If you’re unsure which hot press machine fits your business, reach out to a trusted supplier for a consultation—they can help tailor a solution to your specific requirements.