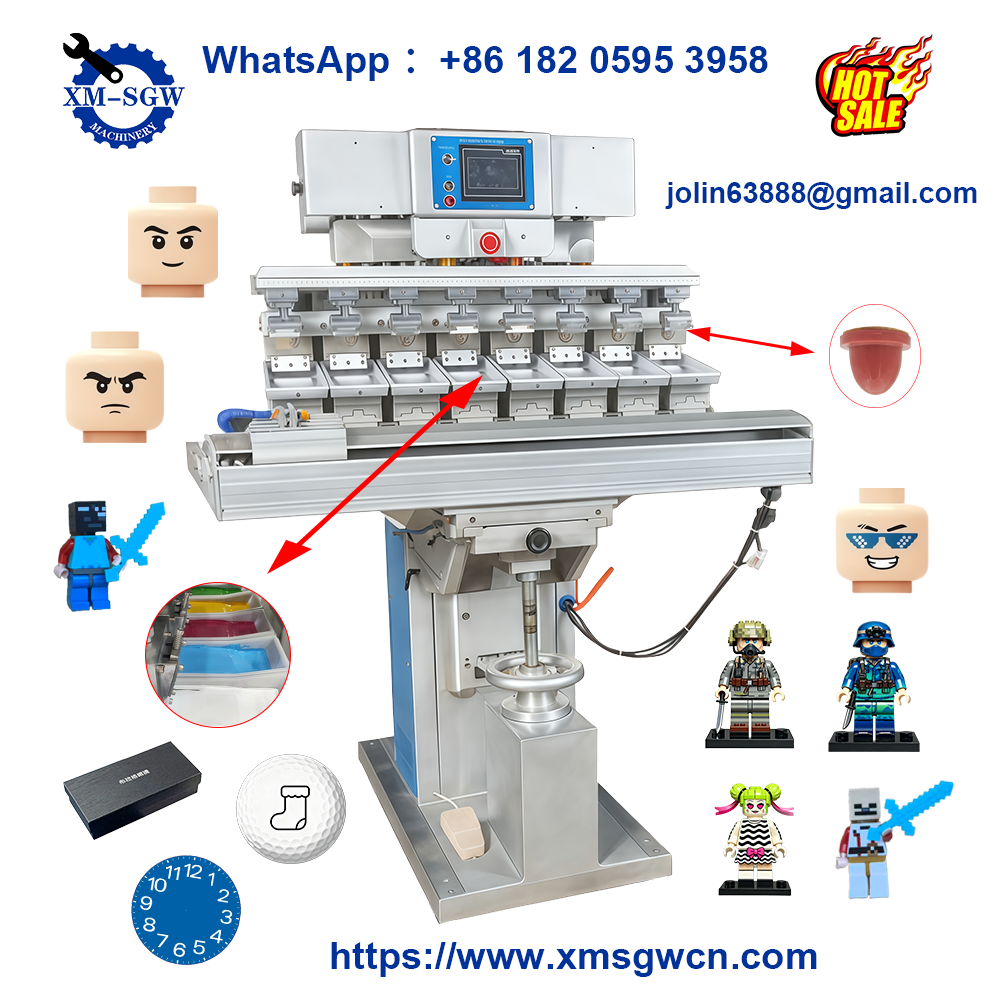

In the world of industrial printing, where intricate designs meet irregular surfaces—think curved plastic parts, small metal components, or even medical devices—pad printing reigns supreme. And at the heart of this versatile technique? The unsung hero: the pad printing steel plate.

Often overlooked but critical to achieving crisp, consistent results, these specialized plates are the bridge between your design and the final product. Let’s dive into what makes pad printing steel plates essential, how they work, and how to choose the right one for your project.

What Are Pad Printing Steel Plates?

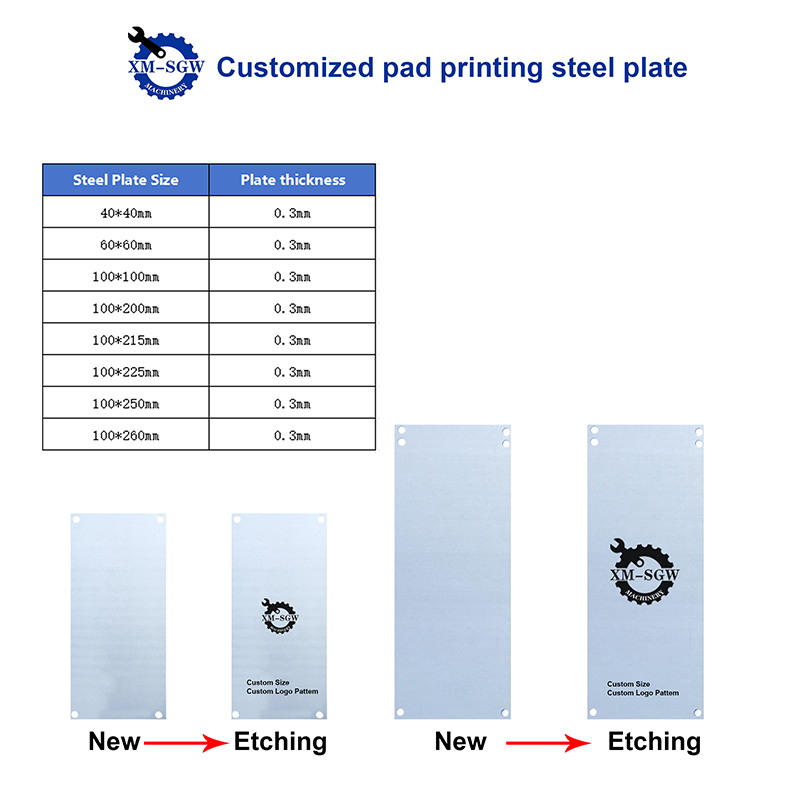

Pad printing steel plates (also called “cliches”) are thin, durable sheets of stainless steel (typically 0.2mm to 0.3mm thick) engineered to carry your design. Their defining feature? A precision-etched recess that holds ink, which is then transferred to a silicone pad and finally onto the target surface.

Unlike other printing methods that rely on flat surfaces, pad printing thrives on complexity—and the steel plate is what makes that precision possible. The etching depth, pattern accuracy, and material quality of the plate directly impact ink transfer, design clarity, and overall print quality.

How Do They Work?

The process is elegant in its simplicity:

- Etching: The design is etched into the steel plate, creating tiny recesses that hold ink.

- Inking: A doctor blade wipes excess ink from the plate’s surface, leaving ink only in the etched recesses.

- Transfer: A flexible silicone pad presses onto the plate, picking up the ink from the recesses.

- Printing: The pad then presses onto the target object, transferring the ink with high fidelity—even onto curved, textured, or small surfaces.

Without a high-quality steel plate, this chain breaks: blurred edges, uneven ink coverage, or failed transfers become inevitable.

Types of Pad Printing Steel Plates: Chemical vs. Laser Etching

Not all steel plates are created equal. The etching method determines their suitability for specific projects:

-

Chemically Etched Plates: Created using acid to dissolve the steel and form the design. Ideal for:

- Large, bold designs (e.g., logos on toys or tools).

- High-volume production (cost-effective for bulk runs).

- Projects where moderate detail (100-200 dpi) is sufficient.

-

Laser Etched Plates: Uses a high-precision laser to vaporize the steel, creating ultra-fine recesses. Perfect for:

- Intricate details (e.g., small text, barcodes, or medical device markings).

- High-definition designs (up to 500 dpi).

- Low to medium production runs where precision is non-negotiable.

How to Choose the Right Steel Plate for Your Project

Selecting the best plate depends on three key factors:

- Design Complexity: Fine text or detailed graphics demand laser etching. Bold, simple designs work well with chemical etching.

- Production Volume: For large batches, chemical etching offers better cost efficiency. Laser plates shine in smaller runs where precision justifies the investment.

- Substrate & Ink Type: Porous substrates (e.g., wood) or thick inks may require deeper etchings (up to 50μm), while smooth surfaces (e.g., plastic) need shallower depths (10-30μm) to avoid smearing.

Maintaining Your Steel Plates: Tips for Longevity

A well-maintained steel plate can last for thousands of prints. Follow these steps to extend its life:

- Clean Gently: Use a soft cloth and mild solvent to remove ink residue—avoid abrasive tools that scratch the surface.

- Store Properly: Keep plates in a dry, dust-free container to prevent corrosion.

- Inspect Regularly: Check for wear, especially around high-stress areas (e.g., sharp design edges). Replace plates at the first sign of blurred transfers.

Final Thoughts: Invest in Quality, Reap the Rewards

Pad printing steel plates are more than just tools—they’re the foundation of consistent, professional results. Whether you’re printing on electronics, automotive parts, or promotional items, choosing the right plate (and caring for it) ensures your designs stand out, even on the trickiest surfaces.

Ready to elevate your pad printing game? Contact us today to discuss custom steel plates tailored to your project’s unique needs. Precision starts here.

Need help selecting the perfect pad printing steel plate? Our experts are standing by. Reach out for a free consultation!