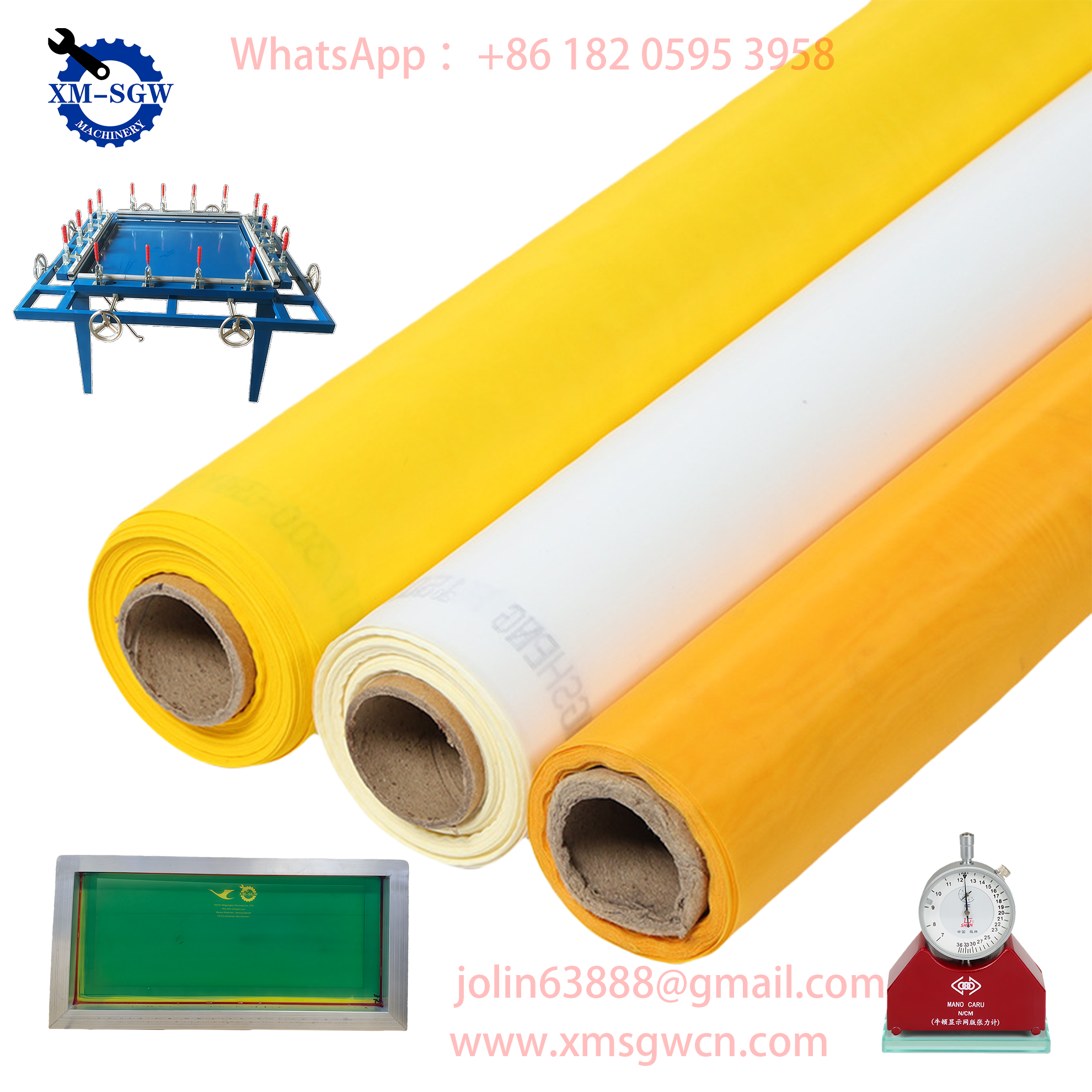

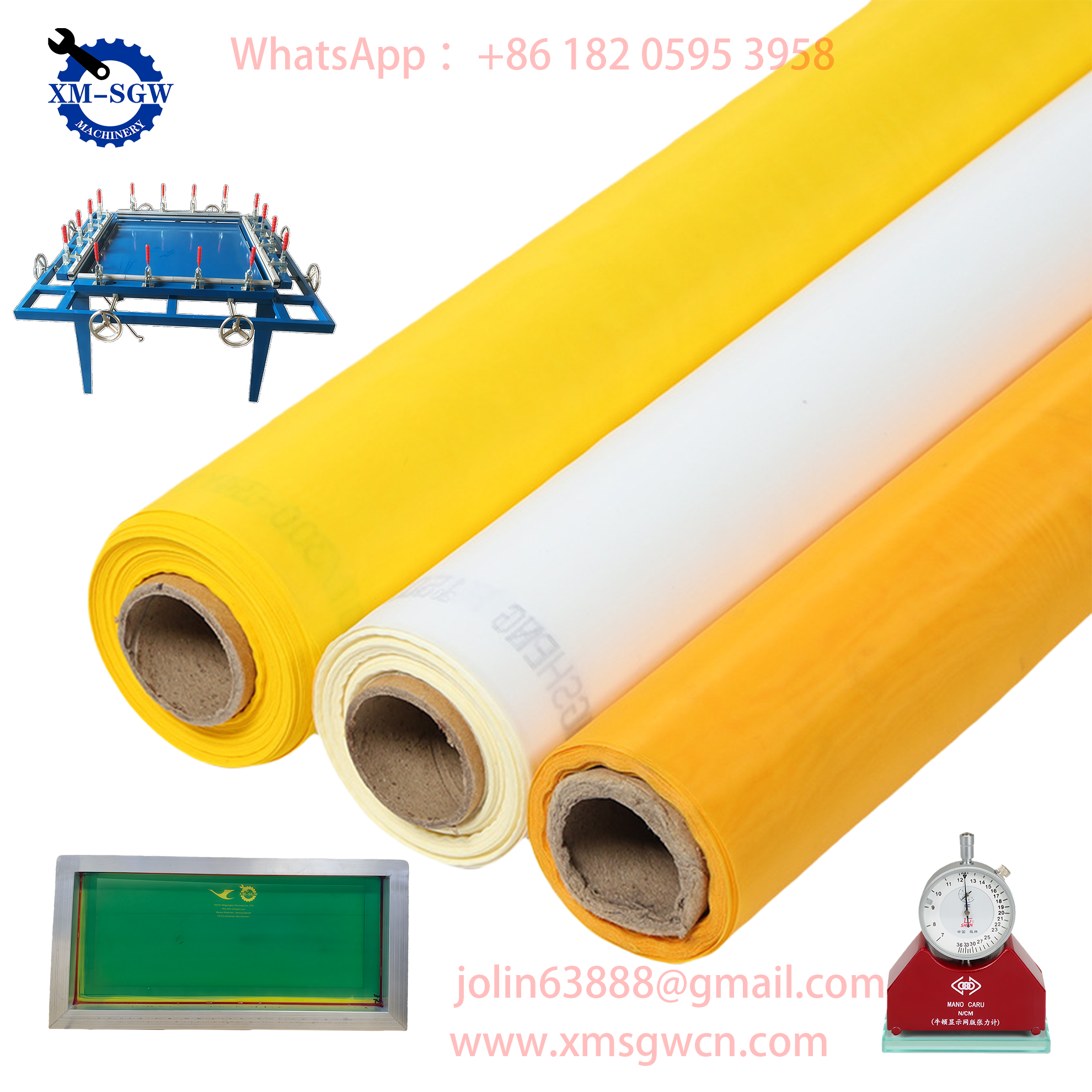

SGW Hot Sale High Precision Polyester Screen Printing Mesh 15-420 Mesh for Screen Printing

Products Categories

Get A Free Quote

High Precision Polyester Screen Printing Mesh Description

Mesh structure is uniform and the dot representation is excellent.

Using high-precision imported steel boxes ensures the consistency of the mesh holes and avoids the deformation of the screen during the printing process, which would cause incorrect alignment.

High tension, low attenuation

By adopting special post-processing techniques, we can meet everyone’s requirements for tension and avoid any damage during the net tensioning process.

Good scratch and print resistance

It is produced using specially imported core materials. The surface contains less soft polyester components, which reduces the wear caused by screen printing and extends the service life.

High Precision Polyester Screen Printing Mesh Detail Display

High Precision Polyester Screen Printing Mesh Data Sheet

How to choose the mesh size

24 and 38 mesh is used mainly for glitter inks that need a very open mesh for printing.

125 mesh is one of the most commonly mesh sizes in screen printing. It works great for printing white ink and other colored inks that have a thicker viscosity.

60 mesh is often used for printing smaller glitter and most shimmer inks.

86 mesh is also used for printing shimmer inks and for laying down thick layers of ink for high-density printing. It also works well for printing foil adhesive.

110 mesh makes printing white and other thick inks easy. It is ideal for spot color printing since it holds less detail than

156 mesh and lays down a thick layer of ink for maximum coverage.

125 mesh is one of the most commonly mesh sizes in screen printing. It works great for printing white ink and other colored inks that have a thicker viscosity.

156 mesh is great for general purpose textile printing with basic to semi-fine detail. It will hold a little finer detail than a 110 mesh while also working well with thinner inks.

200 mesh is great for printing more detailed prints that need a thinner layer of ink than a 156 mesh. It works very well with thinner inks and is a good middle-range mesh size.

230 mesh is great for high-end fine detail printing. A 230 mesh can hold halftones very well and also lets a little more ink

through then a 305 mesh. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

280 mesh screens are great for high-end fine detail printing. A 280 mesh can hold halftones very well and also lets

a little more ink through then a 305 mesh.

a little more ink through then a 305 mesh.

305 mesh holds extremely high detail, letting through only a thin layer of ink. This allows for a very soft hand on the garment and is great for use in printing halftones and process prints. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

High Precision Polyester Screen Printing Mesh Applications

High Precision Polyester Screen Printing Mesh Video