In the realm of industrial marking and coding, precision, versatility, and efficiency are non-negotiable. CO2 laser marking machines have emerged as a cornerstone technology, trusted by manufacturers across industries to deliver high-quality, permanent marks on a wide range of materials. Unlike traditional marking methods such as inkjet printing or mechanical engraving, CO2 laser systems offer non-contact processing, minimal material waste, and exceptional consistency—making them an ideal solution for modern production lines. This guide delves into the working principles, key benefits, applications, and selection tips for CO2 laser marking machines, helping you determine if this technology aligns with your operational needs.

How Do CO2 Laser Marking Machines Work?

How Do CO2 Laser Marking Machines Work?

CO2 laser marking machines operate by generating a high-energy infrared laser beam (typically with a wavelength of 10.6 μm) using a carbon dioxide gas mixture as the lasing medium. The laser beam is amplified, collimated, and focused through a series of optical components to a tiny spot on the target material. When the laser interacts with the material, it causes a controlled thermal reaction—such as ablation (vaporization of the surface layer), discoloration, or carbonization—without physically contacting the material.

This non-contact process eliminates the risk of material damage, wear on tools, and contamination, which is particularly critical for delicate or sterile products. The laser’s intensity, speed, and focus can be precisely adjusted via software, allowing for customizable mark sizes, depths, and patterns—from fine text and barcodes to complex logos and serial numbers.

Key Advantages of CO2 Laser Marking Machines

Key Advantages of CO2 Laser Marking Machines

1. Versatility Across Materials

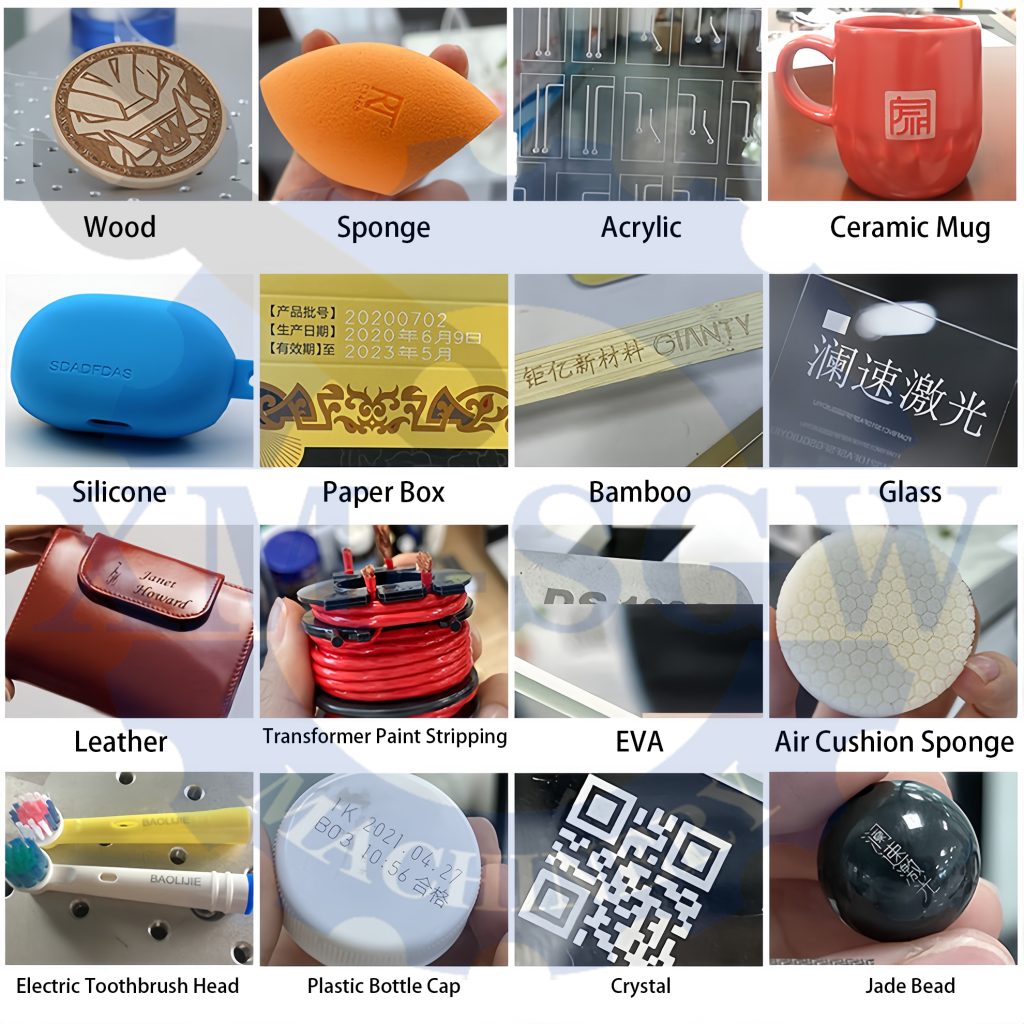

CO2 lasers excel at marking organic materials and some synthetic substrates, including wood, paper, cardboard, leather, fabric, acrylic, plastic (ABS, PVC, PP), glass, and even certain ceramics. This versatility makes them suitable for diverse industries, from packaging and textiles to electronics and medical devices.

2. Permanent and High-Contrast Marks

The marks created by CO2 lasers are resistant to fading, smudging, and abrasion, ensuring long-term readability and traceability. This is essential for compliance with industry regulations (e.g., FDA requirements for medical devices, ISO standards for product labeling) and anti-counterfeiting efforts.

3. Precision and Speed

CO2 laser systems can achieve marking resolutions as high as 1200 DPI, enabling crisp, detailed marks even on small components. Additionally, their fast processing speed (up to several meters per second) integrates seamlessly into high-volume production lines, reducing bottlenecks and improving overall efficiency.

4. Low Operational Costs

Unlike inkjet printers that require frequent ink replacements or mechanical engravers that need tool maintenance, CO2 lasers have minimal consumables. The laser tube (the core component) has a lifespan of 8,000–20,000 operating hours, and routine maintenance is simple—translating to lower long-term operational costs.

5. Eco-Friendly Operation

CO2 laser marking produces no ink waste, volatile organic compounds (VOCs), or harmful emissions, making it an environmentally sustainable alternative to traditional marking methods. This aligns with the growing demand for green manufacturing practices.

Top Applications of CO2 Laser Marking Machines

Top Applications of CO2 Laser Marking Machines

The flexibility of CO2 laser technology makes it indispensable in numerous industries:

- Packaging Industry: Marking expiration dates, batch codes, barcodes, and logos on food packaging (cardboard, plastic films), beverage bottles (glass, PET), and cosmetic containers.

- Electronics Industry: Engraving part numbers, serial numbers, and QR codes on circuit boards, plastic casings, and cables.

- Textile and Apparel Industry: Cutting and marking fabric, leather, and synthetic materials for clothing, footwear, and accessories—enabling custom designs and brand labeling.

- Medical Industry: Marking sterile medical devices (syringes, surgical tools, implants) with unique identifiers for traceability, adhering to strict hygiene standards.

- Woodworking and Crafts: Creating intricate designs, personalized messages, and decorative patterns on wood, plywood, and MDF for furniture, toys, and artisanal products.

- Automotive Industry: Marking rubber components (hoses, gaskets), plastic parts, and interior trim with part numbers and safety information.

How to Choose the Right CO2 Laser Marking Machine

How to Choose the Right CO2 Laser Marking Machine

Selecting the optimal CO2 laser marking machine depends on your specific application requirements. Consider the following factors:

1. Laser Power

Power ranges from 10W to 100W+. For thin materials (paper, fabric, thin plastic), 10–30W is sufficient. For thicker materials (wood, acrylic, glass) or deeper engraving, opt for 50W+ models.

2. Marking Area

Choose a marking area that matches the size of your workpieces. Standard areas range from 100x100mm to 300x300mm, but custom sizes are available for large-scale applications.

3. Software Compatibility

Ensure the machine’s software supports common file formats (AI, DXF, PNG, JPG) and integrates with your existing production management systems. User-friendly software with auto-marking and batch processing features will streamline operations.

4. Cooling System

Smaller machines (≤30W) use air cooling, which is compact and low-maintenance. Larger, high-power machines require water cooling to prevent overheating and ensure stable performance.

5. After-Sales Support

Opt for a supplier that offers reliable after-sales service, including technical support, spare parts, and maintenance training. A reputable manufacturer will also provide a warranty (typically 1–2 years) for core components.

Conclusion

Conclusion

CO2 laser marking machines combine precision, versatility, and cost-effectiveness to meet the evolving demands of modern manufacturing. Whether you need to enhance product traceability, comply with industry regulations, or create custom designs, this technology delivers consistent, high-quality results across a wide range of materials. By understanding your application needs and evaluating key factors such as power, marking area, and software compatibility, you can select a CO2 laser system that boosts efficiency, reduces costs, and gives your business a competitive edge.

Ready to integrate CO₂ laser marking into your production line? Contact our team of experts to discuss custom solutions tailored to your industry and workflow.