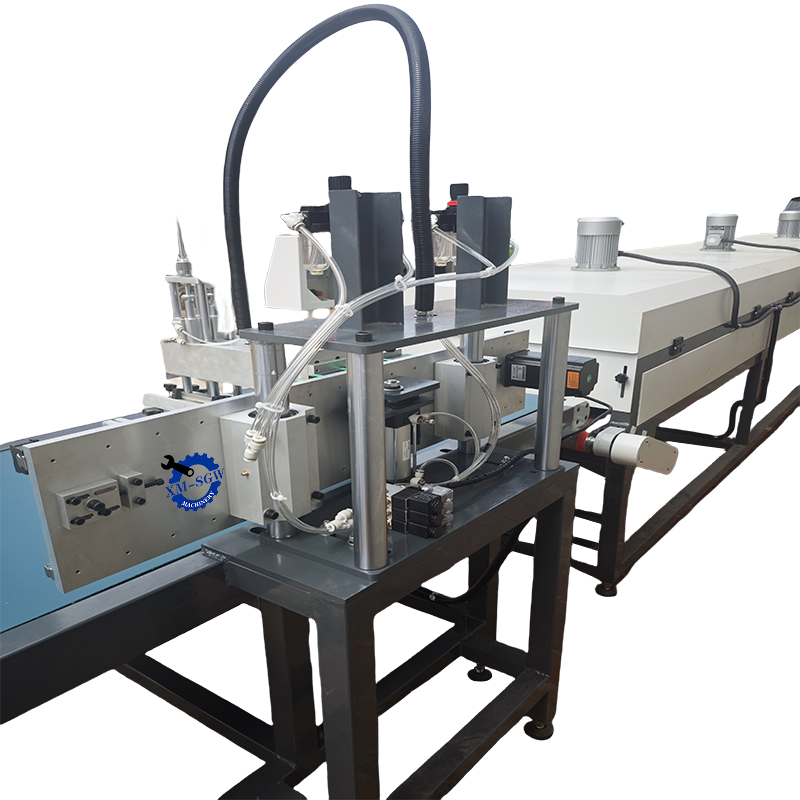

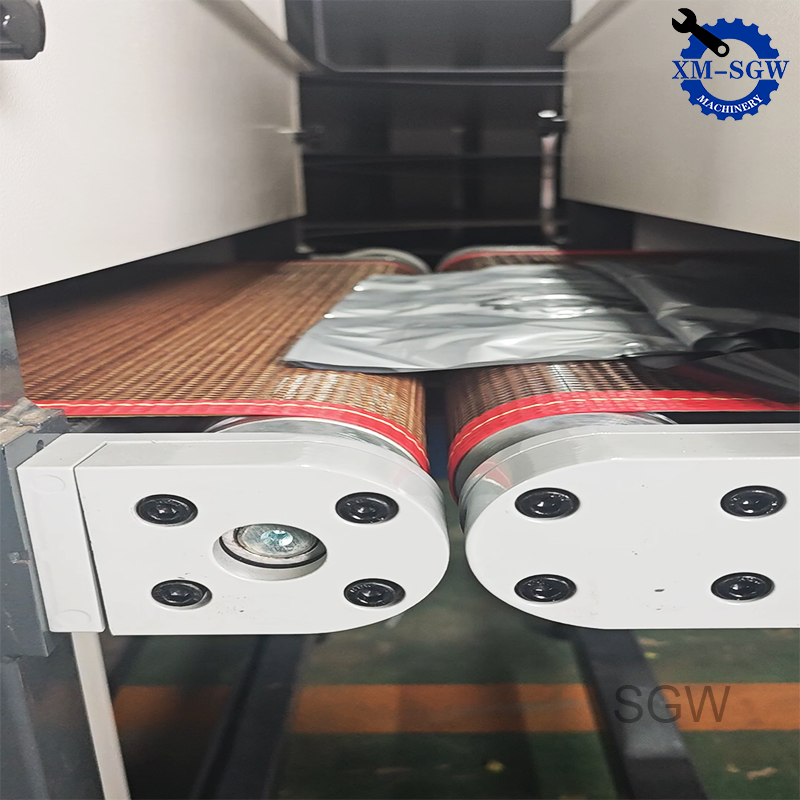

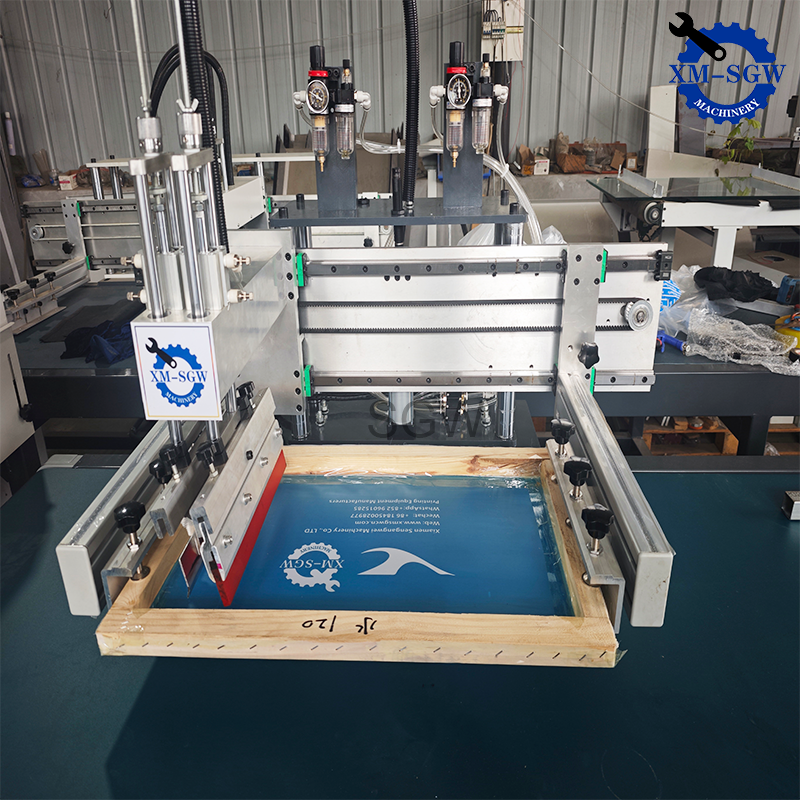

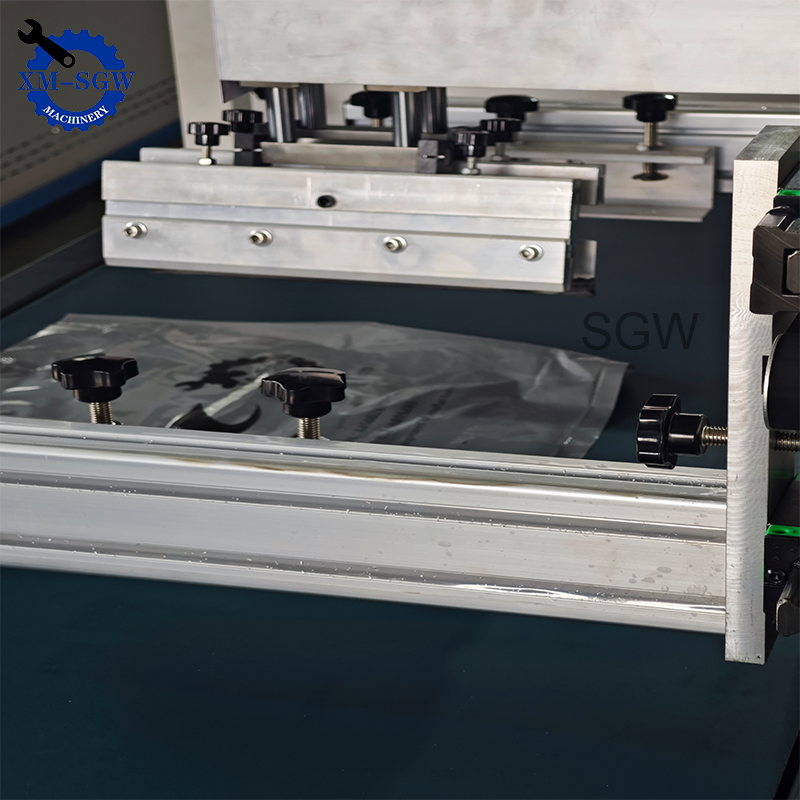

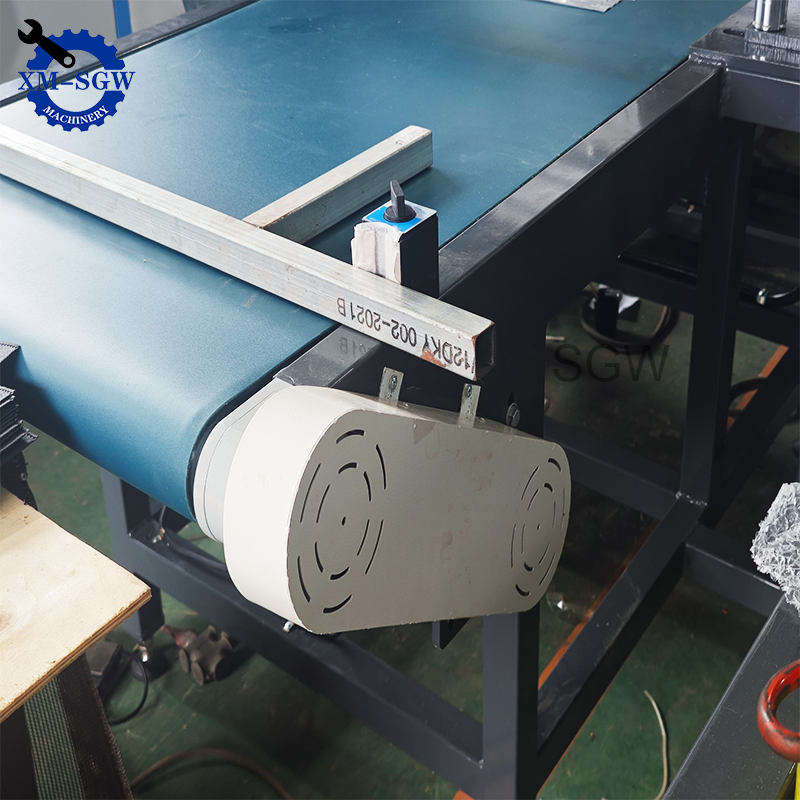

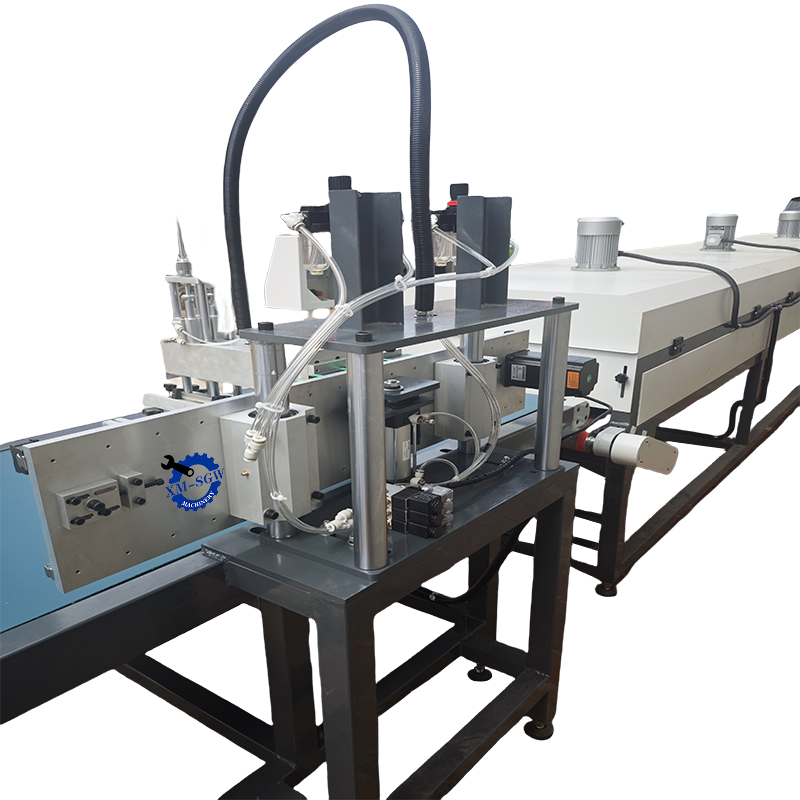

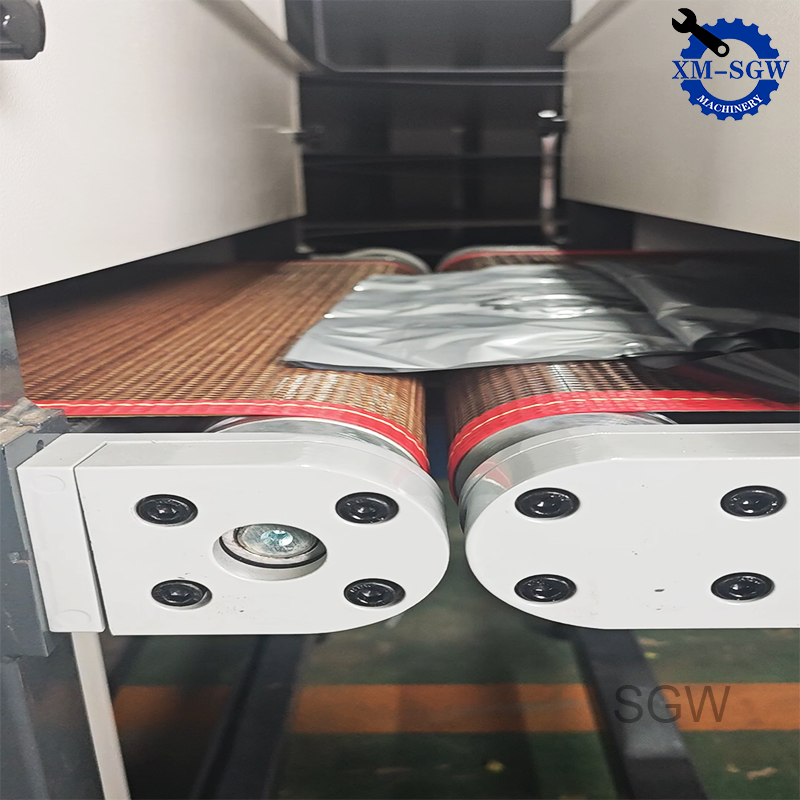

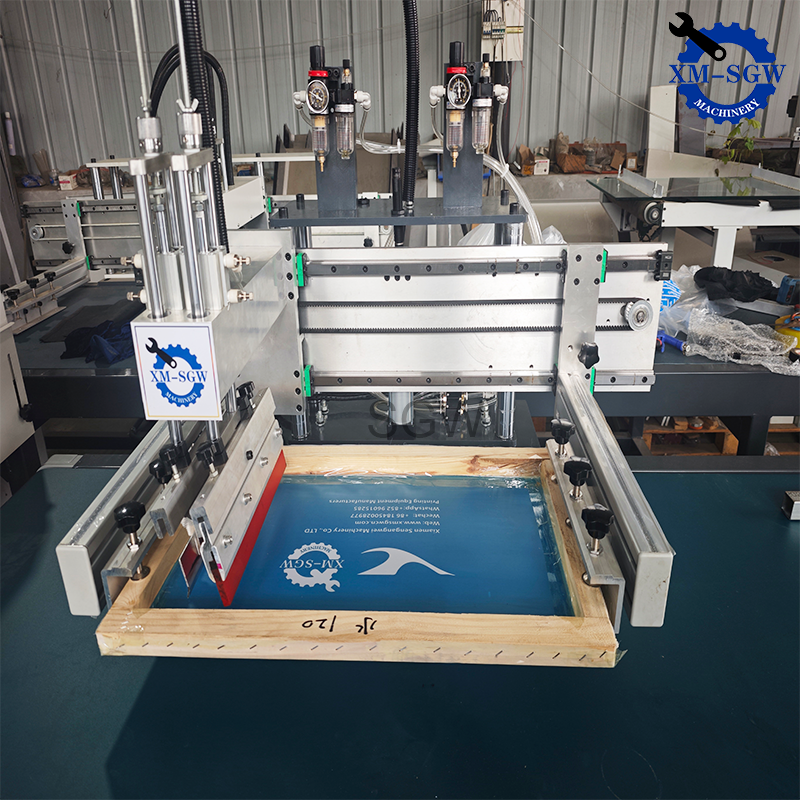

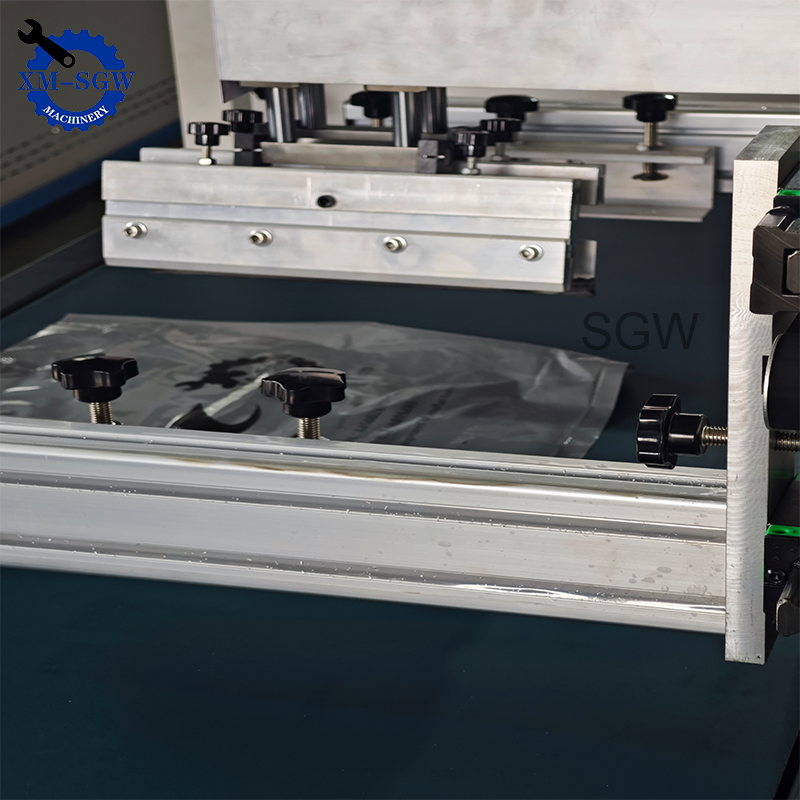

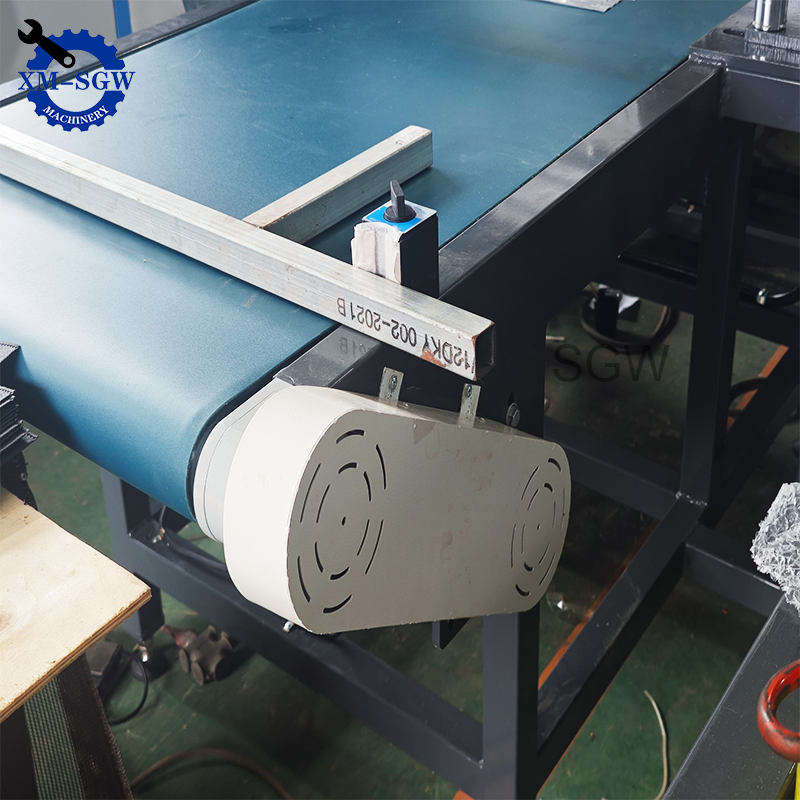

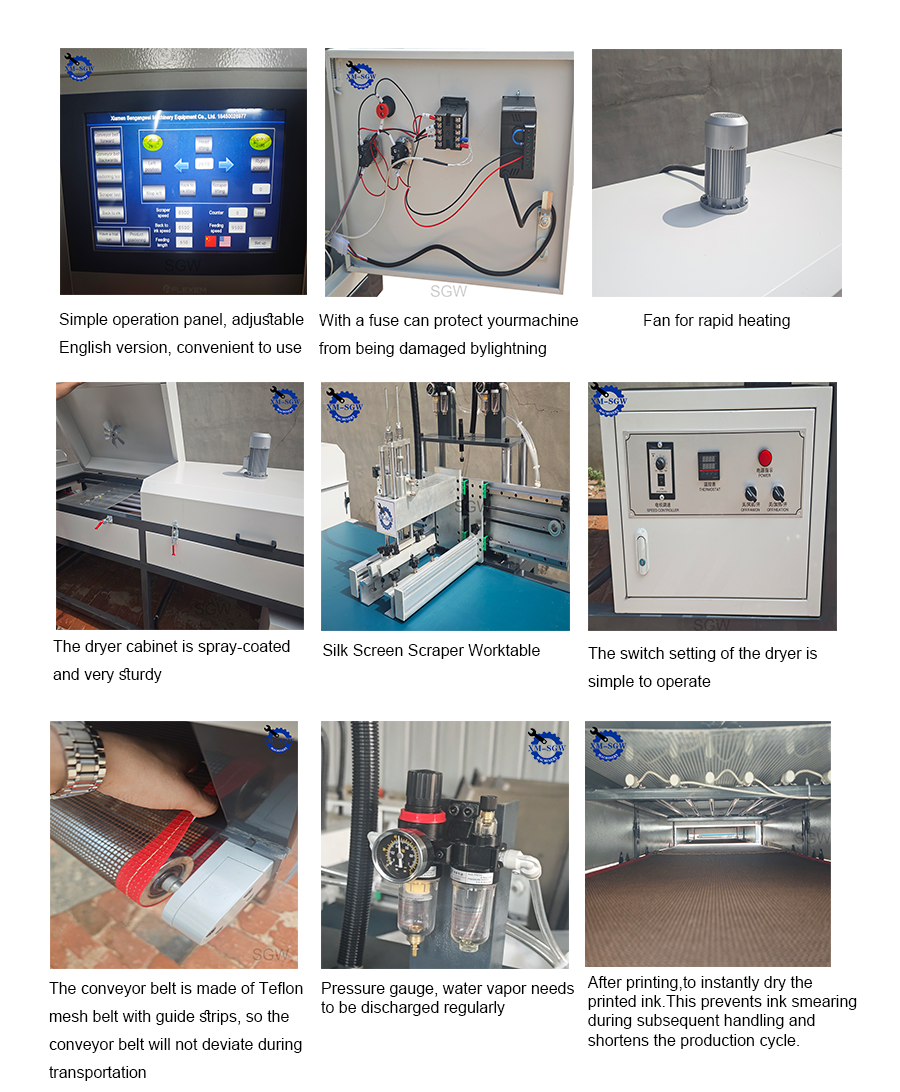

Automatic Bag Screen Printer With Conveyor Belt Drying Oven New Condition for Paper Bag Printing

Automatic Bag Screen Printer Description

Automatic Bag Screen Printer Data Sheet

| Key Selling Points | High-accuracy |

| Printing speed | 1500pcs/hr |

| Countertop area | 550*400MM |

| Adjustable Screen Frame Elevation | 80 mm |

| Stroke of Squeegee & oil Blade(Up/Down) | 32 mm |

| Weight | 300KG |

| Main body size | 2000*850*1600 mm |

| Print taper | ±7-15 |

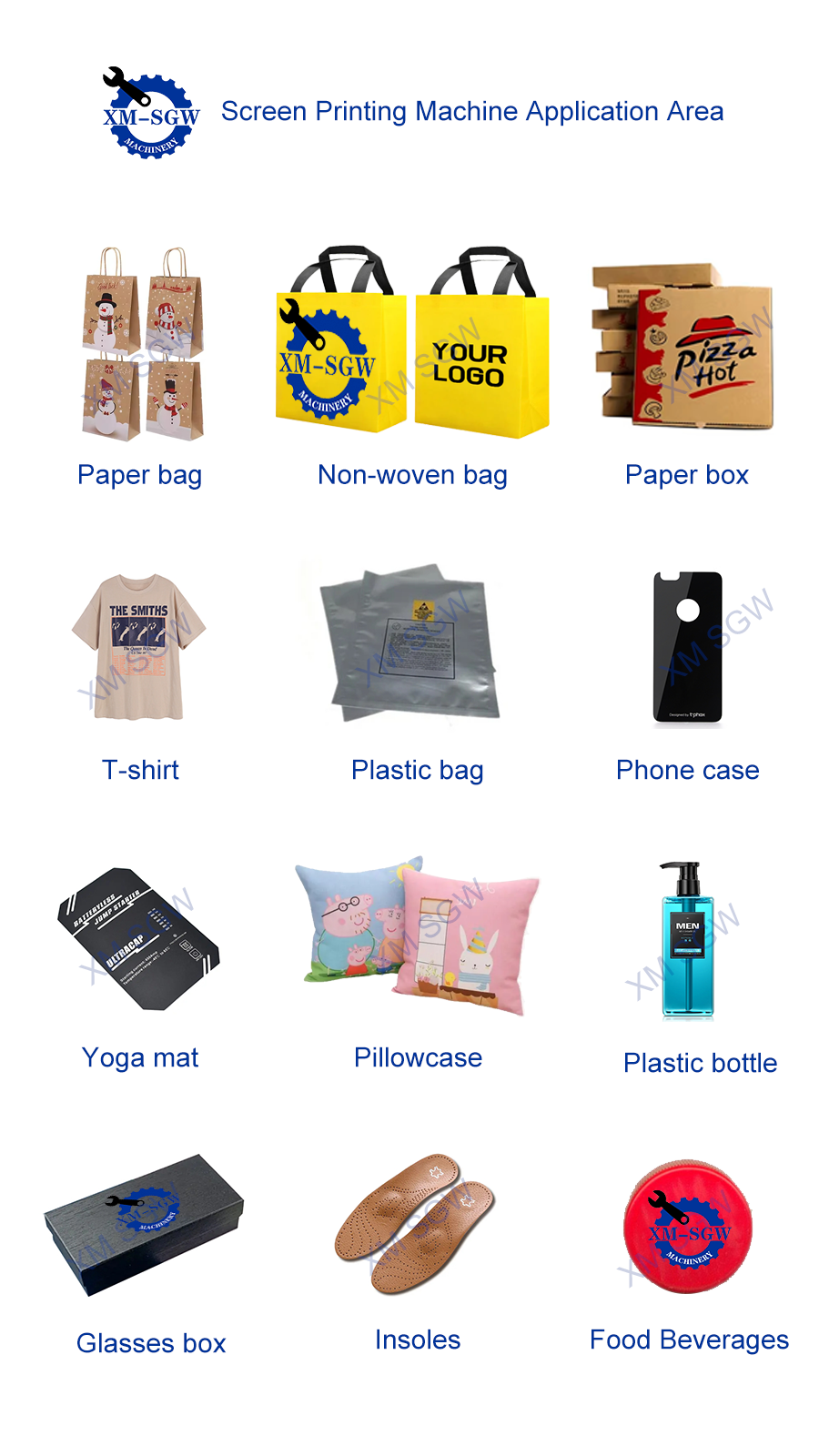

Automatic Bag Screen Printer Applications

Flat Silk Screen Printing Machine Printing Products

Such as Products for businesscard, lense, lens, Silicone Keypad gift item, T-shirt, baby cloth, bra, toys, umbrella, underwear,insole, garment, face mask, shopping bag, industry fabric, Electronic Products, Battery, Powerbank, Package Box, Color Box Circuit boards, Textile transfers, Paper , Stickers, Membrane switch,Signage, Glass, Wooden board, PVC film.cigarette case, wine case, gift box, card paper, trademark, wall Calendary, painting, computer keyboard, transfer paper, adhesive paper, credit card etc.

Q1: What types of silk screen printers are available in your product line?

A1: We offer a comprehensive range of Silk Screen Printer (also referred to as Screen Printers) to meet diverse production needs. Our lineup includes three core types: Manual silk screen printers (ideal for small-batch customization and low-volume production), Semi-Automatic models (balancing efficiency and flexibility for medium-scale operations), and Automatic / Fully Automatic screen printers (designed for high-speed, large-volume production with minimal human intervention). Whether you’re printing on cups, bottles, glassware, or other substrates, we have the right equipment to match your workflow.

Q2: Are your screen printers certified to comply with international market regulations?

A2: Yes, all our Screen Printers (including manual, semi-automatic, and fully automatic variants) are CE Certified, ensuring they meet strict European safety, health, and environmental protection standards. Additionally, for customers targeting the French and German markets, our equipment is fully compliant with EPR France (Packaging) and EPR Germany – Packaging requirements. This compliance eliminates regulatory barriers, allowing you to export and market your printed products seamlessly across these regions.

Q3: What’s the difference between your Automatic and Fully Automatic silk screen printers?

A3: Both our Automatic and Fully Automatic Silk Screen Printer models deliver enhanced efficiency compared to manual or semi-automatic options. The key distinction lies in automation depth: our Automatic models handle core printing processes (e.g., substrate feeding, printing, and curing) but may require occasional manual oversight for setup adjustments. In contrast, the Fully Automatic variants integrate end-to-end automation—including automatic substrate loading/unloading, precise registration control, defect detection, and batch sorting—enabling 24/7 unattended operation. Both are CE Certified and compliant with EPR France (Packaging) and EPR Germany – Packaging standards, making them suitable for high-volume production of printed cups, bottles, glassware, and other items.

Get Free Quote of Automatic Bag Screen Printer

Related Products

Related News

In a world where brand visibility matters more than ever, custom-printed bags have become a powerful marketing tool. From retail […]

In today’s fast-paced manufacturing landscape, efficiency and consistency are non-negotiable. For businesses requiring large-scale printing on flat or slightly curved […]

In the world of screen printing, every detail matters. From ink selection to machine calibration, each element plays […]