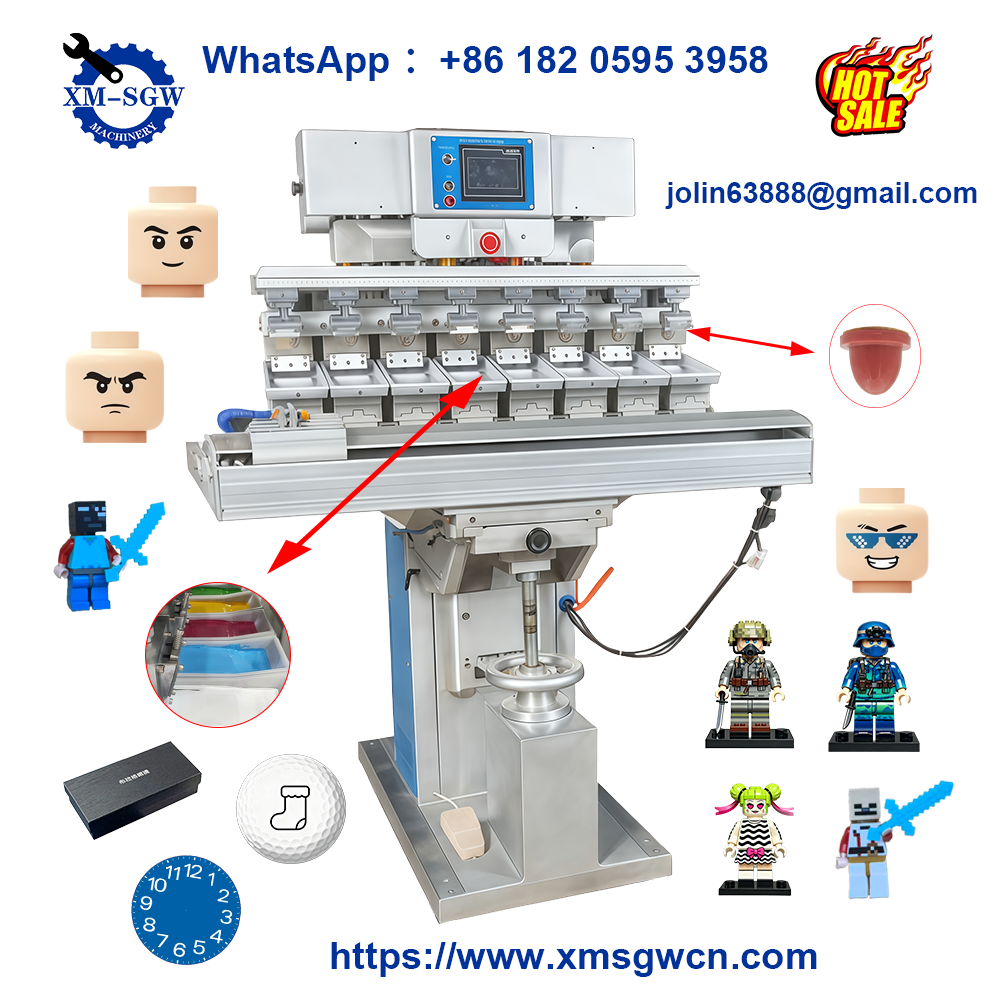

Best Selling 8 Color 360° Rotating Table Pad Printing Machine for Logo Customizable Abs Material Lego Toys

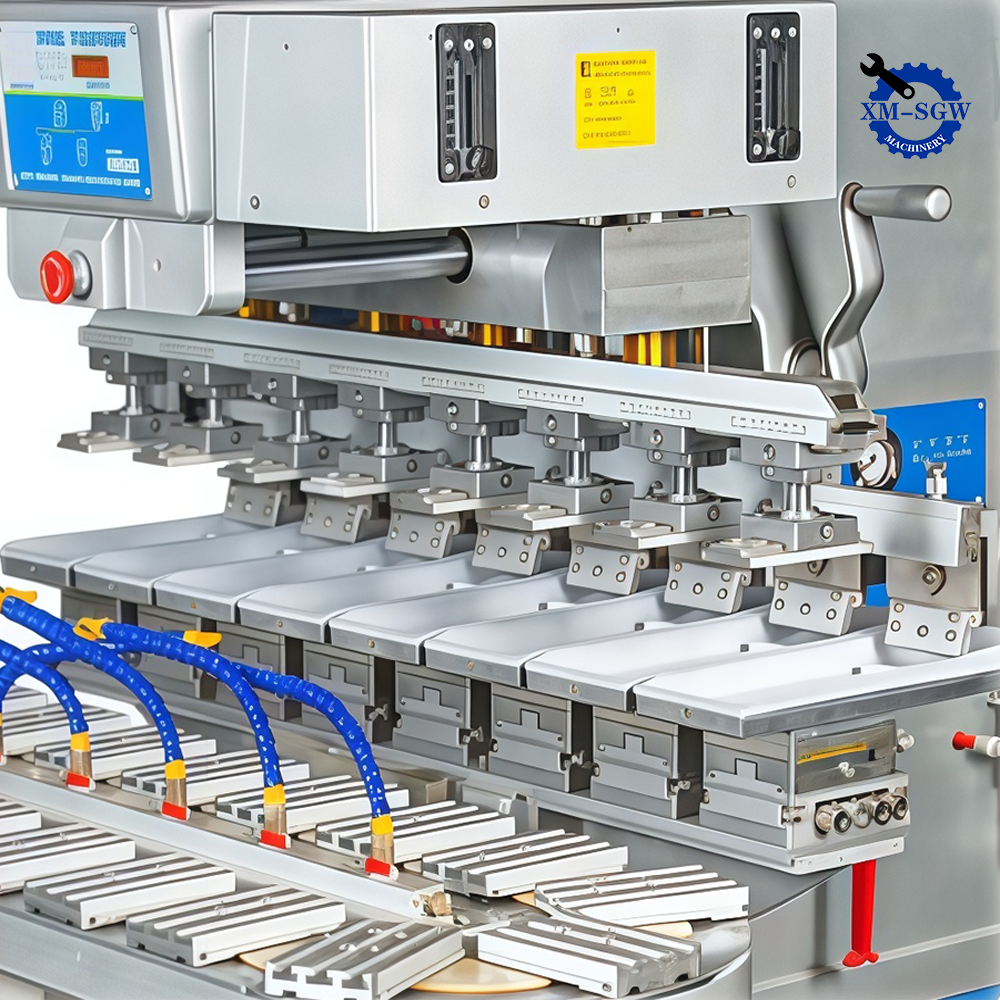

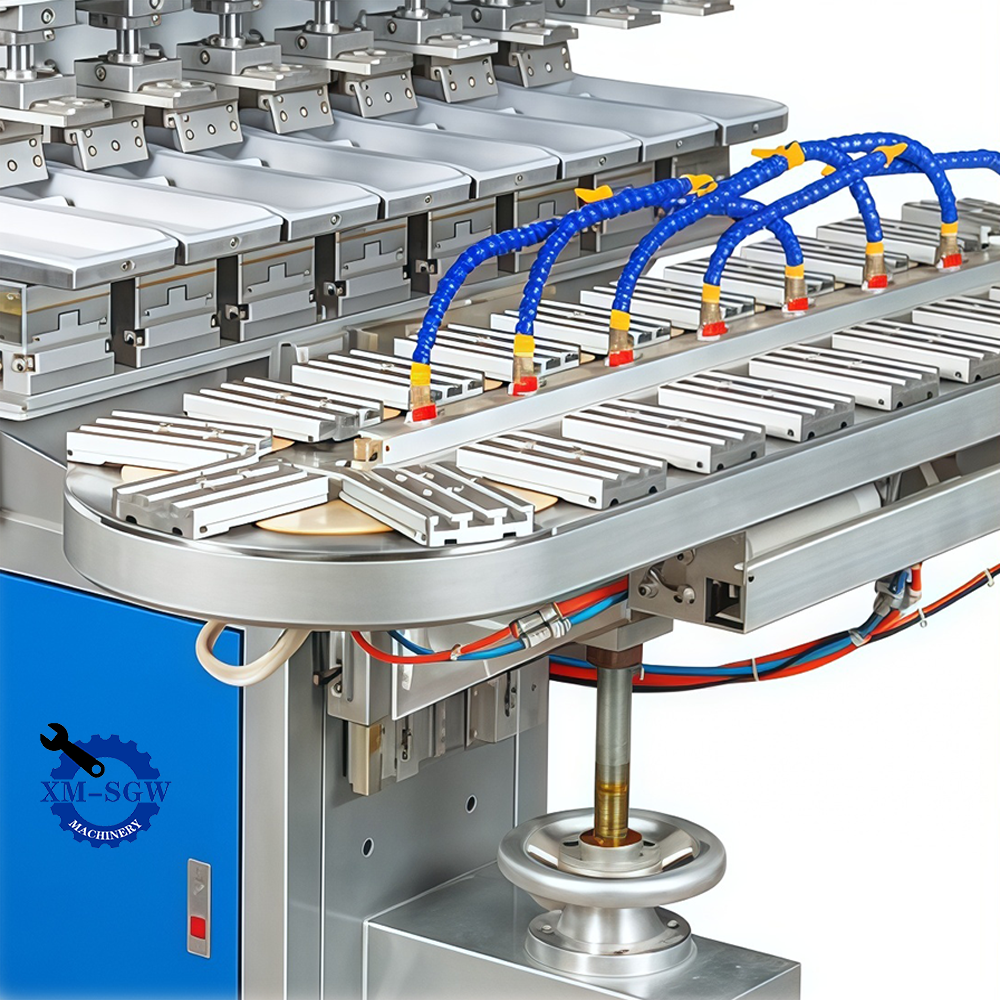

2. Turntable Automation Boosts High Efficiency

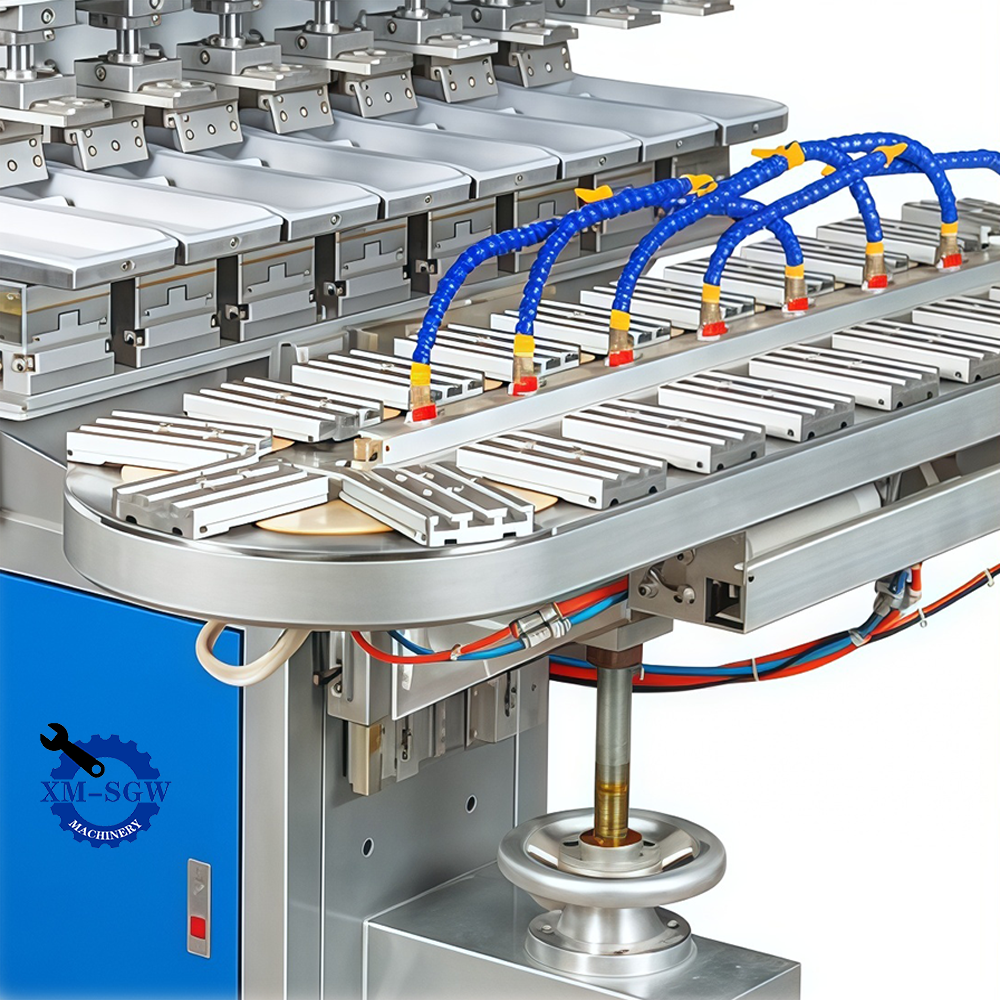

Motor-driven turntable with precise indexing (6–12 stations optional) supports continuous batch production. Hourly output reaches 2000–3000 pieces (4–5x faster than manual multi-color printing), ideal for medium-to-large batches (2500–5000 units) like toy

parts or cosmetic components.

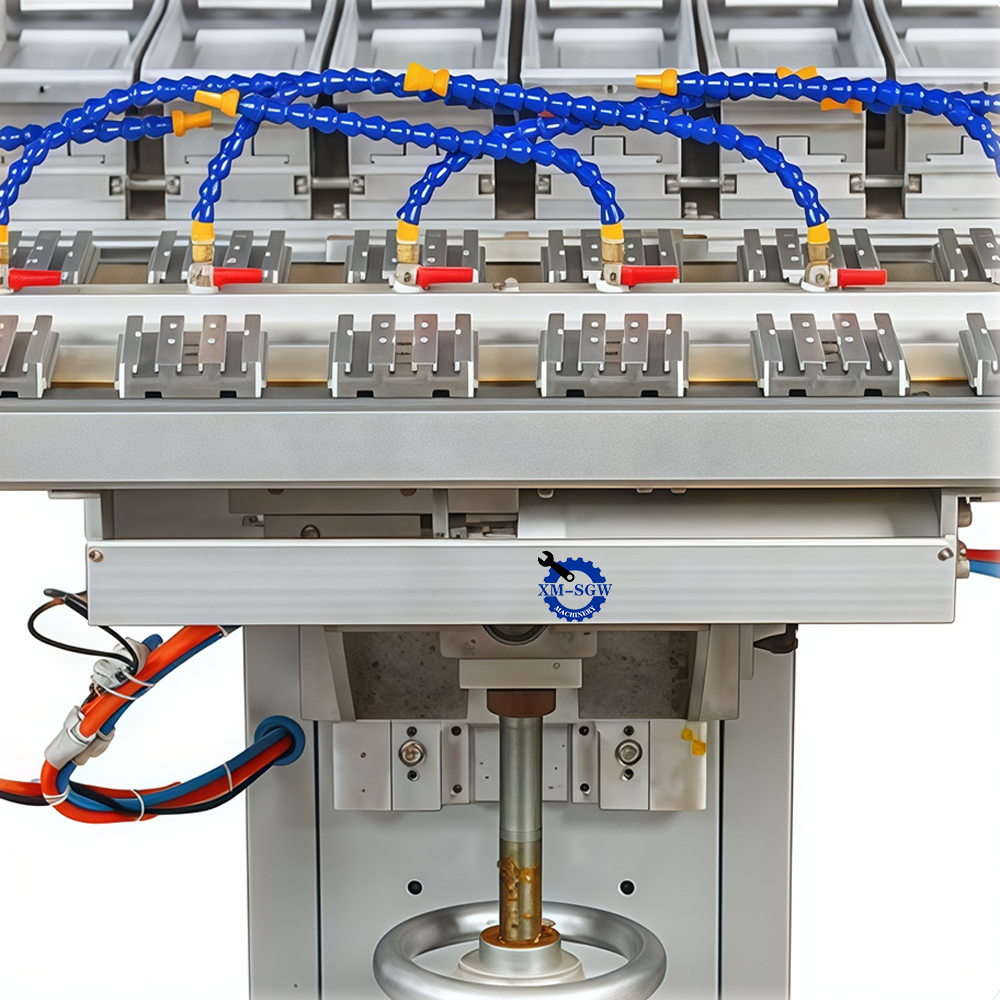

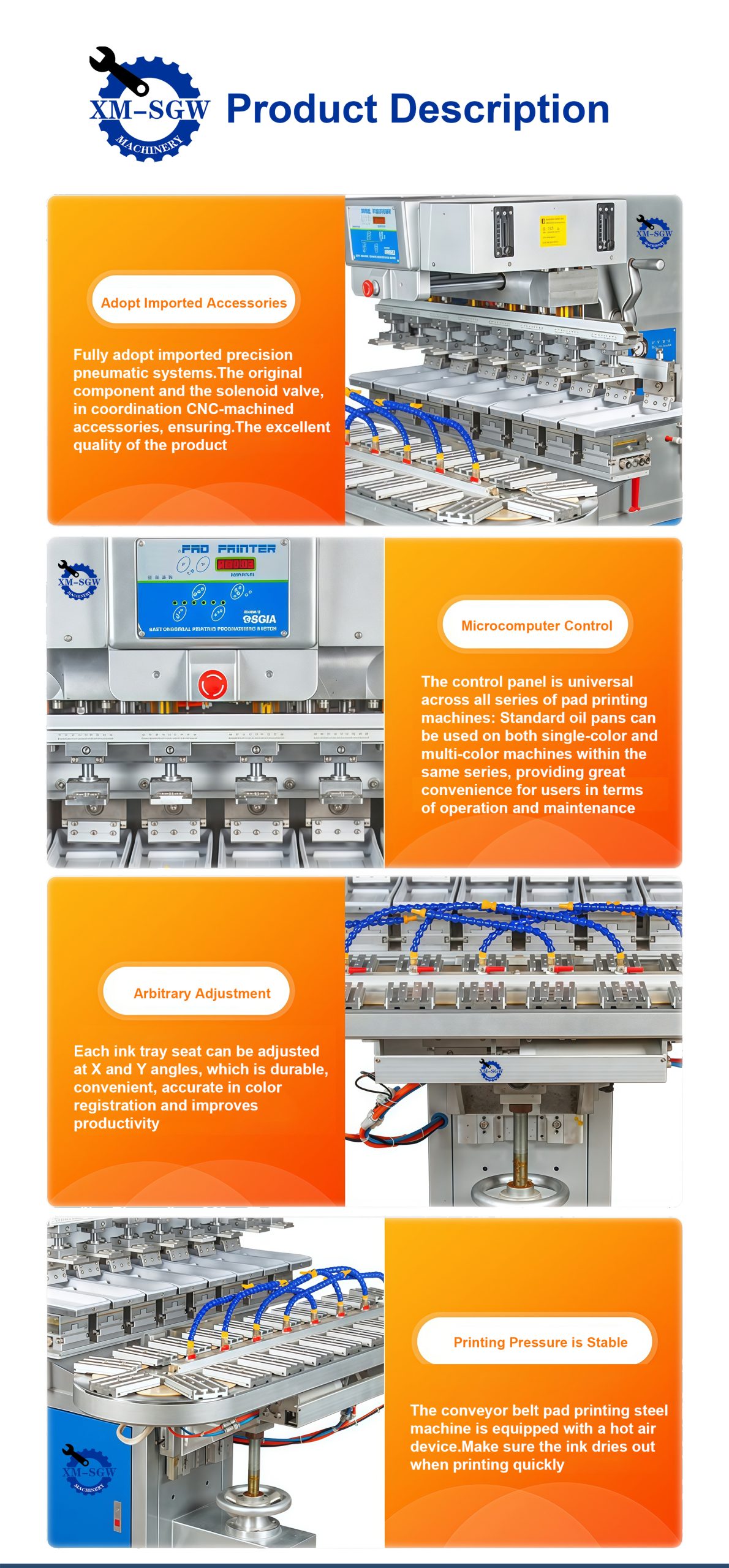

3. Ultra-Precise Color Registration

Equipped with servo-driven turntable positioning (accuracy ±0.02mm) and synchronized color station calibration. Ensures no color misalignment—critical for fine multi-color details (e.g., electronic device logos, medical consumable labels) where color accuracy affects brand recognition or compliance.

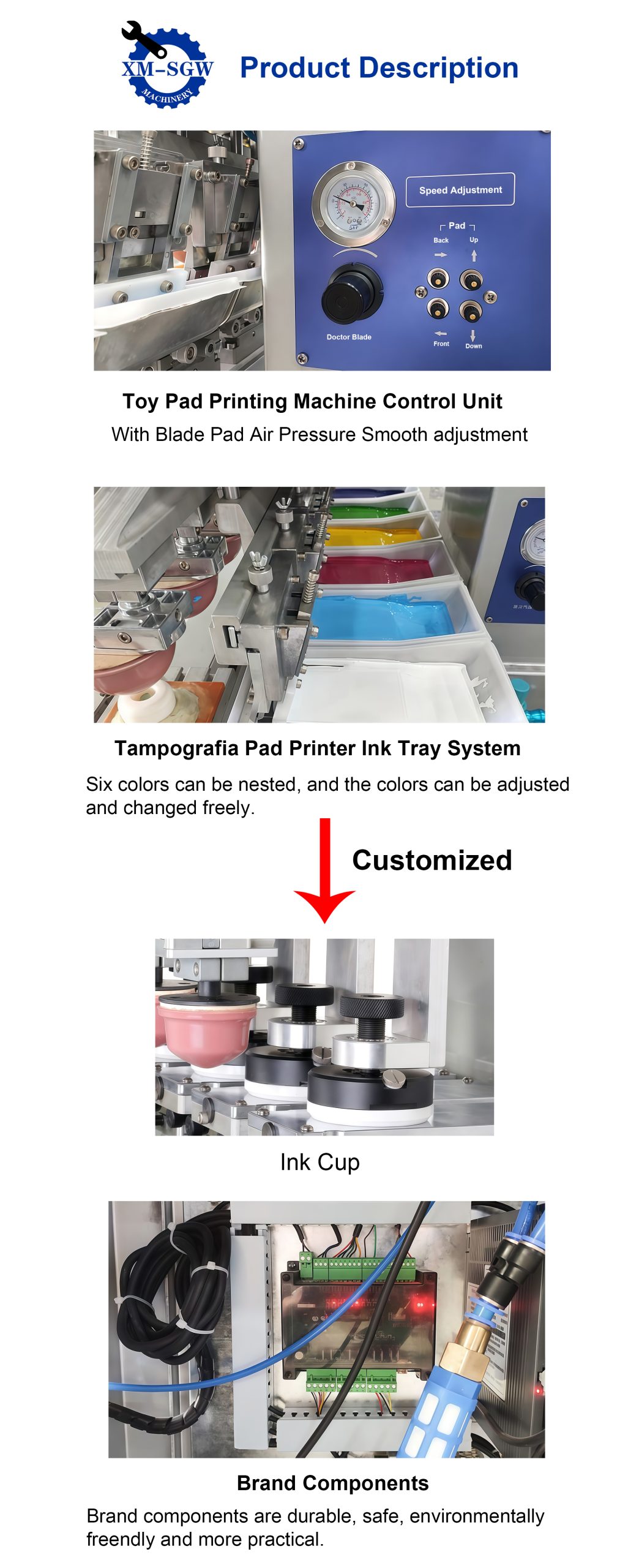

4. Flexible Color Configuration & Quick Changeovers

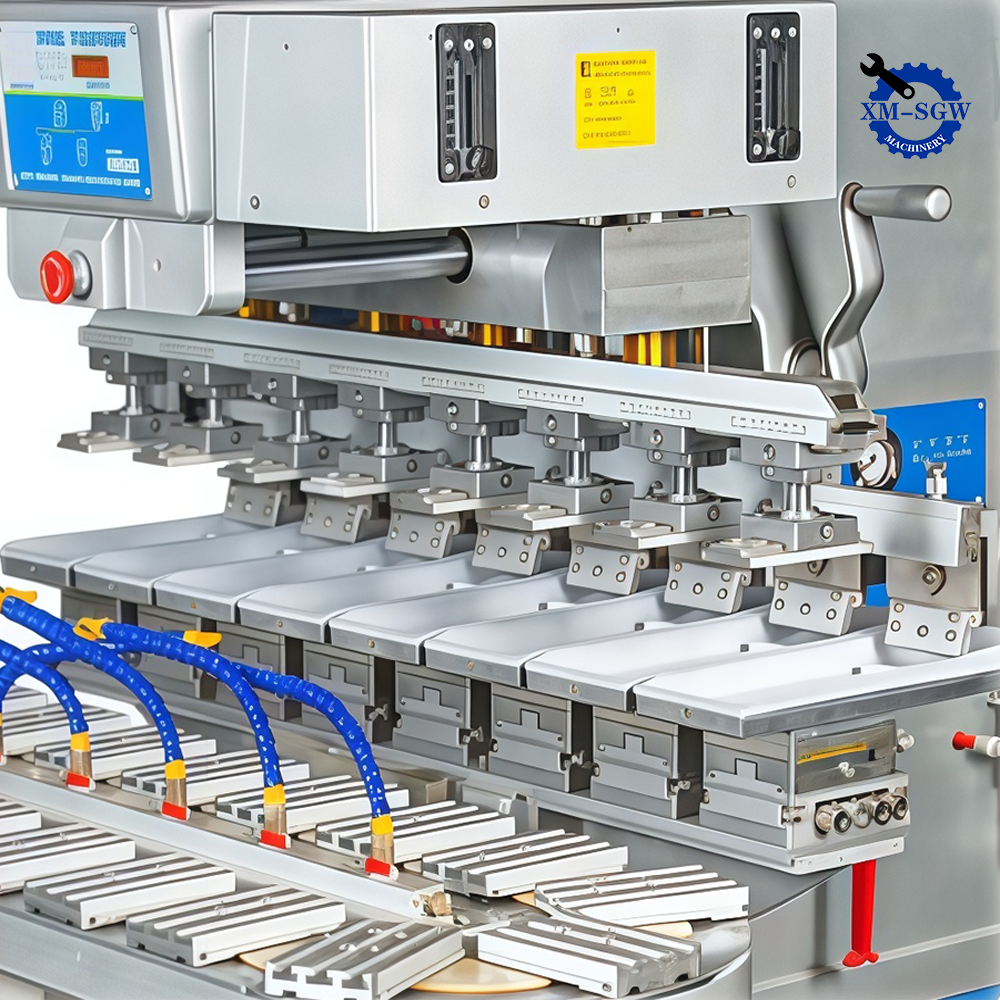

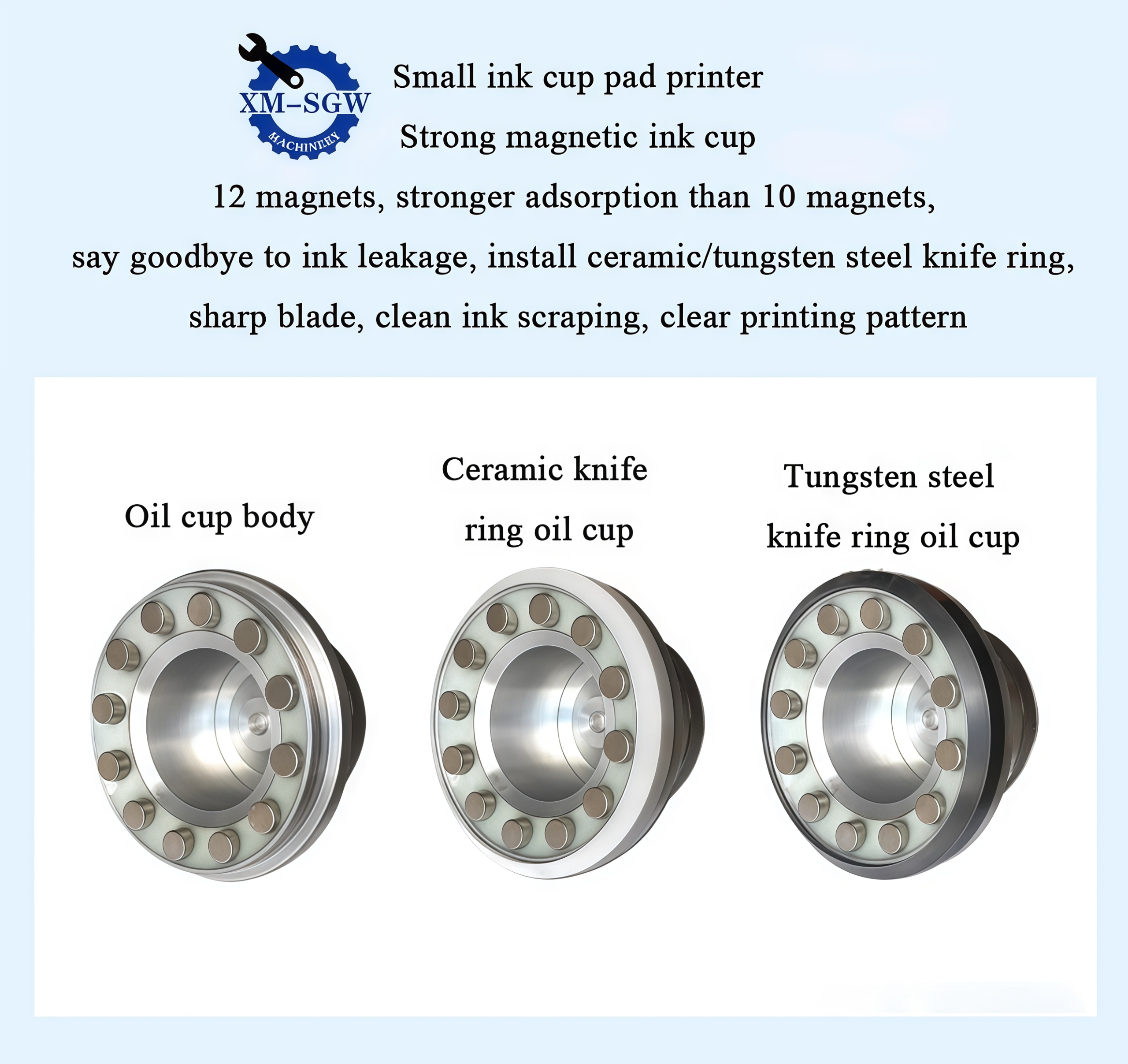

Supports 2–8 color free combination (no need to use all 8 stations) for diverse order needs. Quick-release ink cups and print plates allow style switching in 15–20 minutes (vs. 30+ minutes for traditional multi-color printers), adapting to small-batch multi-style production.

5. Wide Adaptability to Irregular/Small Workpieces

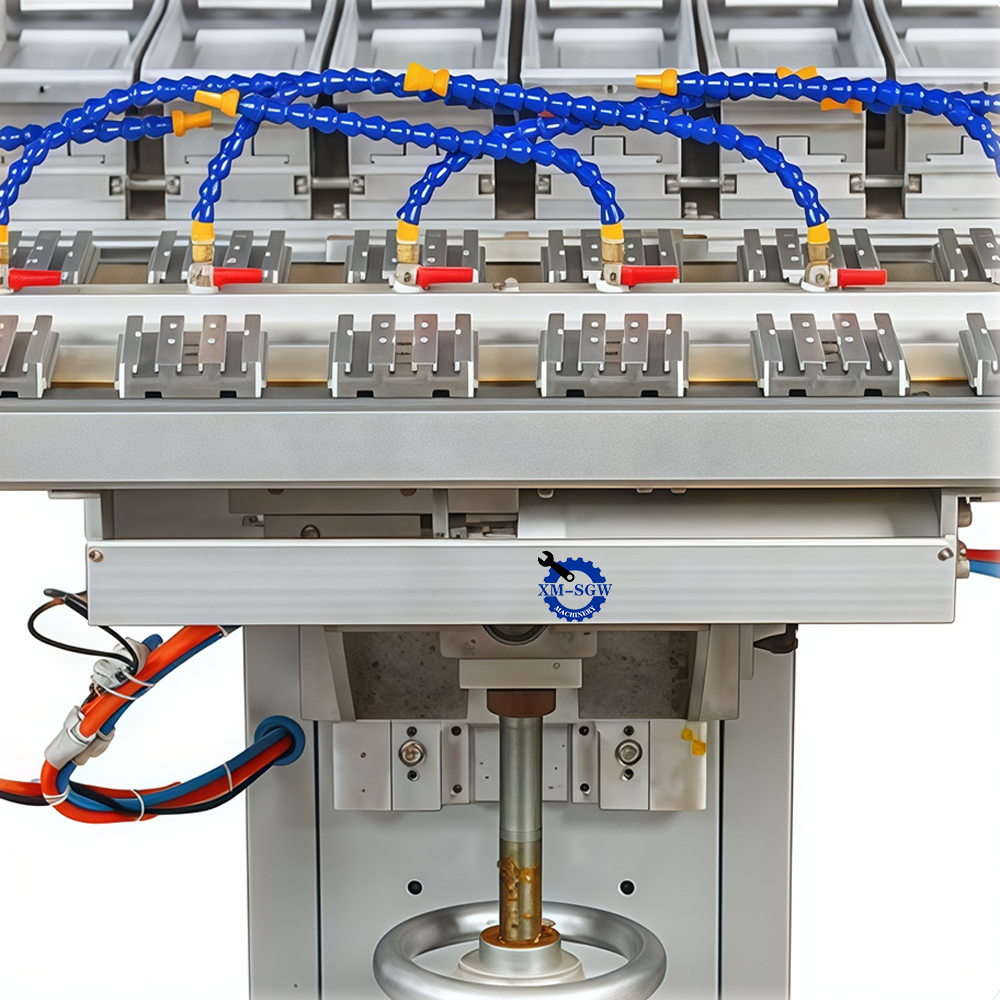

Adjustable turntable height (10–100mm) and 8 independent print heads fit workpieces of various shapes/sizes: curved surfaces(e.g., lipstick tubes, bottle caps), tiny parts (e.g., earphone shells, watch dials), or uneven surfaces (e.g., toy wheels,hardware handles).

6. Cost-Saving vs. Multiple Single-Color Printers

One 8-color turntable machine replaces 4–6 single-color printers, saving 50% workshop space and 30% labor costs (no need for multiple operators). Low ink waste (closed ink cup design reduces evaporation by 40%) and shared maintenance parts cut long-term operational costs.

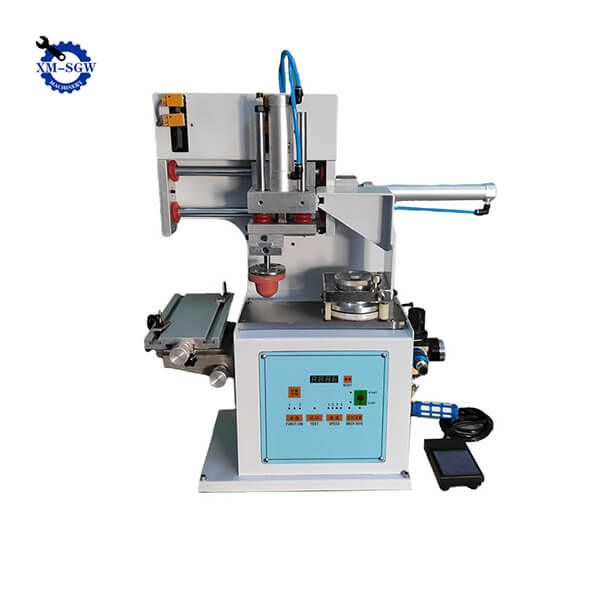

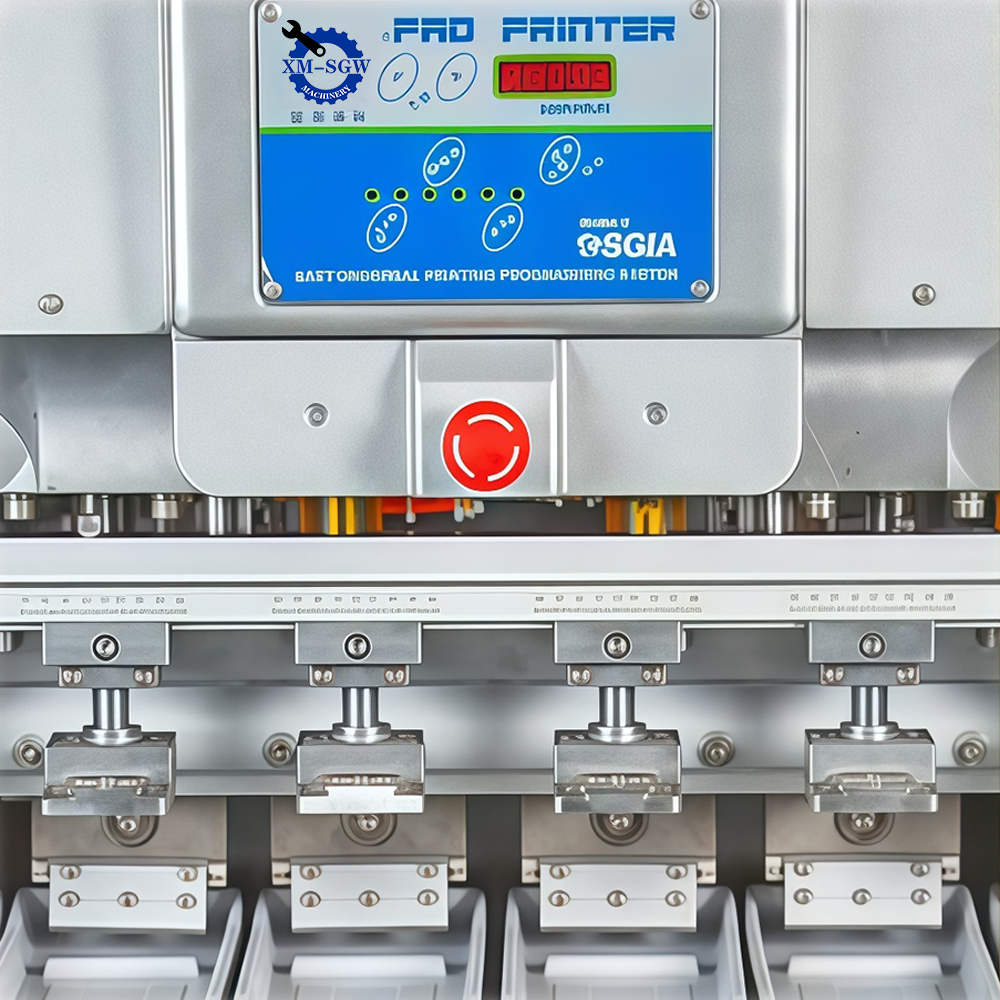

7. User-Friendly Operation & Smart Control

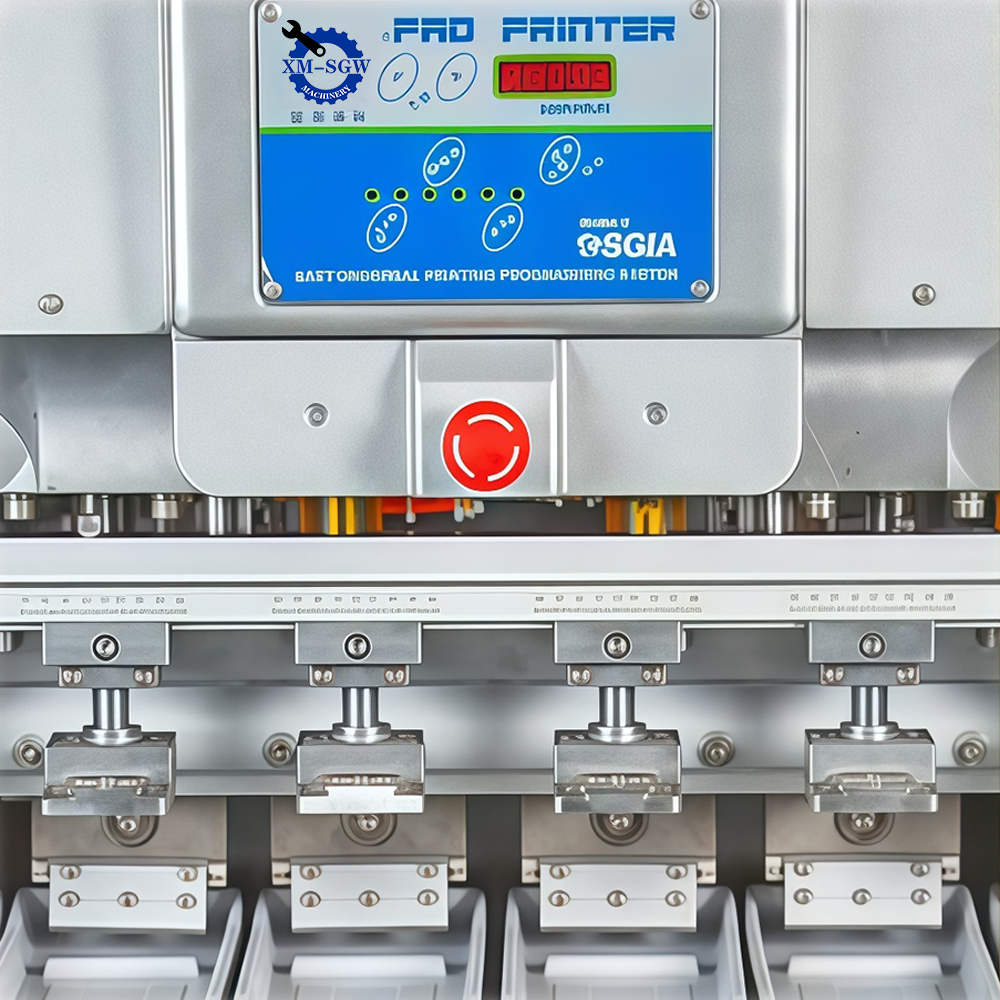

7-inch touchscreen with pre-set printing parameters (stored 50+ groups) for easy operation—new staff master it in 1 day. Auto-ink supply and error alerts (e.g., low ink, pressure anomaly) reduce manual monitoring and minimize downtime.

8. Durable Build & Compliance with Industry Standards

Heavy-duty metal frame (load-bearing 50kg) resists vibration during long-term operation. Meets CE/RoHS standards with safety features: emergency stop button, protective covers for moving parts, and overheat protection—suitable for industrial workshops.

Motor-driven turntable with precise indexing (6–12 stations optional) supports continuous batch production. Hourly output reaches 2000–3000 pieces (4–5x faster than manual multi-color printing), ideal for medium-to-large batches (2500–5000 units) like toy

parts or cosmetic components.

3. Ultra-Precise Color Registration

Equipped with servo-driven turntable positioning (accuracy ±0.02mm) and synchronized color station calibration. Ensures no color misalignment—critical for fine multi-color details (e.g., electronic device logos, medical consumable labels) where color accuracy affects brand recognition or compliance.

4. Flexible Color Configuration & Quick Changeovers

Supports 2–8 color free combination (no need to use all 8 stations) for diverse order needs. Quick-release ink cups and print plates allow style switching in 15–20 minutes (vs. 30+ minutes for traditional multi-color printers), adapting to small-batch multi-style production.

5. Wide Adaptability to Irregular/Small Workpieces

Adjustable turntable height (10–100mm) and 8 independent print heads fit workpieces of various shapes/sizes: curved surfaces(e.g., lipstick tubes, bottle caps), tiny parts (e.g., earphone shells, watch dials), or uneven surfaces (e.g., toy wheels,hardware handles).

6. Cost-Saving vs. Multiple Single-Color Printers

One 8-color turntable machine replaces 4–6 single-color printers, saving 50% workshop space and 30% labor costs (no need for multiple operators). Low ink waste (closed ink cup design reduces evaporation by 40%) and shared maintenance parts cut long-term operational costs.

7. User-Friendly Operation & Smart Control

7-inch touchscreen with pre-set printing parameters (stored 50+ groups) for easy operation—new staff master it in 1 day. Auto-ink supply and error alerts (e.g., low ink, pressure anomaly) reduce manual monitoring and minimize downtime.

8. Durable Build & Compliance with Industry Standards

Heavy-duty metal frame (load-bearing 50kg) resists vibration during long-term operation. Meets CE/RoHS standards with safety features: emergency stop button, protective covers for moving parts, and overheat protection—suitable for industrial workshops.

Products Categories

Get A Free Quote

8 Color 360° Rotating Table Pad Printing Machine for Logo Description

8 Color 360° Rotating Table Pad Printing Machine for Logo Technical

| Maximum printing speed | 3000PCS/HR |

| Maximum assembly pressure | 0.3-0.7MPa |

| Weight | 350KG |

| Maximum printing area | 100*150mm 100*250mm open ink well tray |

| Max print size | 70*120mm / 70*170mm / customize |

| Voltage/Hz | 220V 50HZ |

| Rotating Table | 360° Rotating Table |

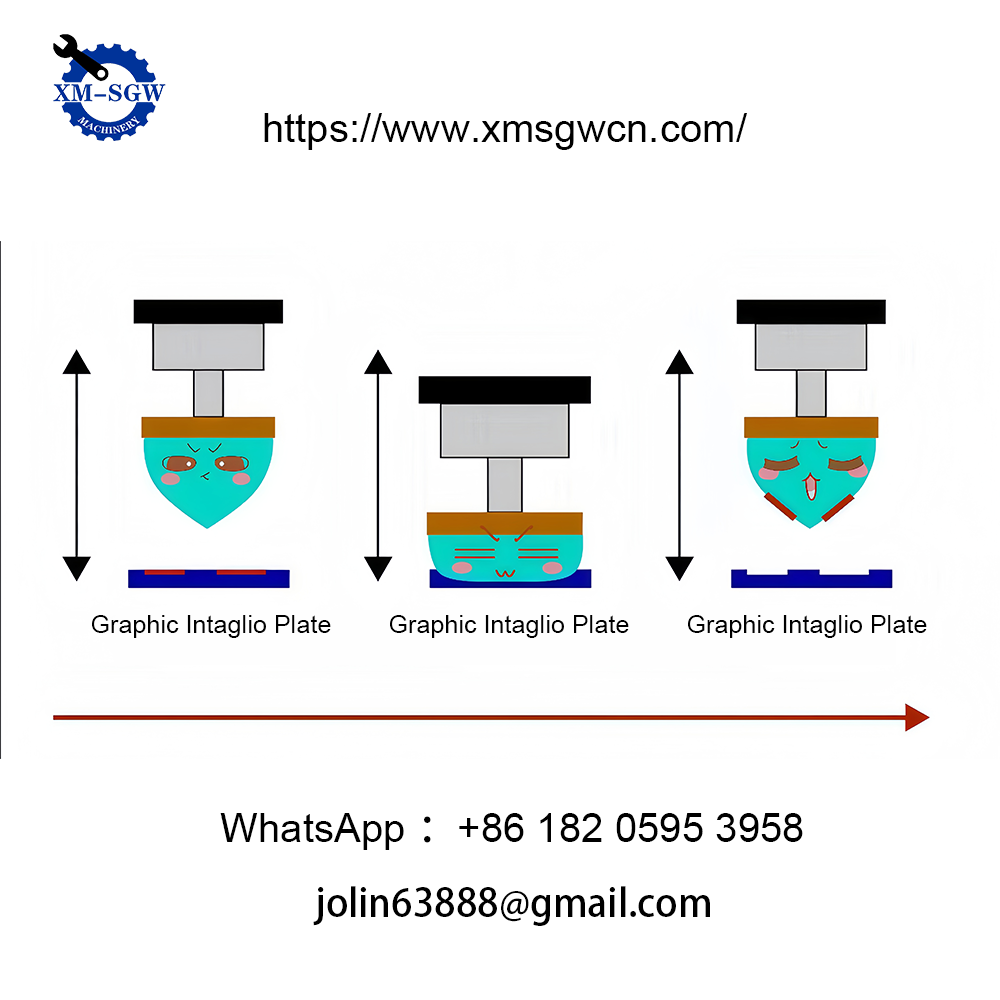

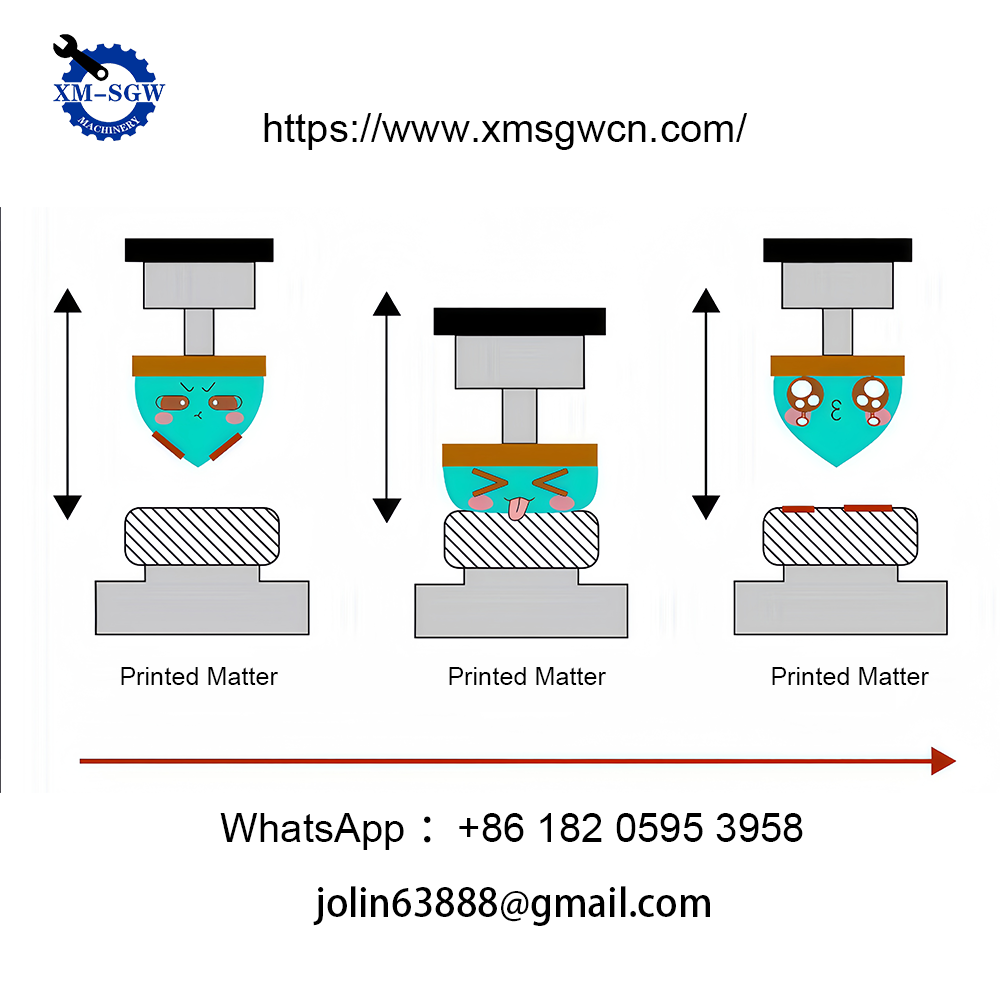

| Pad Pressure | Adjustable Pad Pressure |

| Control | Microprocessor Control |

| Printing | High Precision Printing |

| Changeover | Quick Changeover |

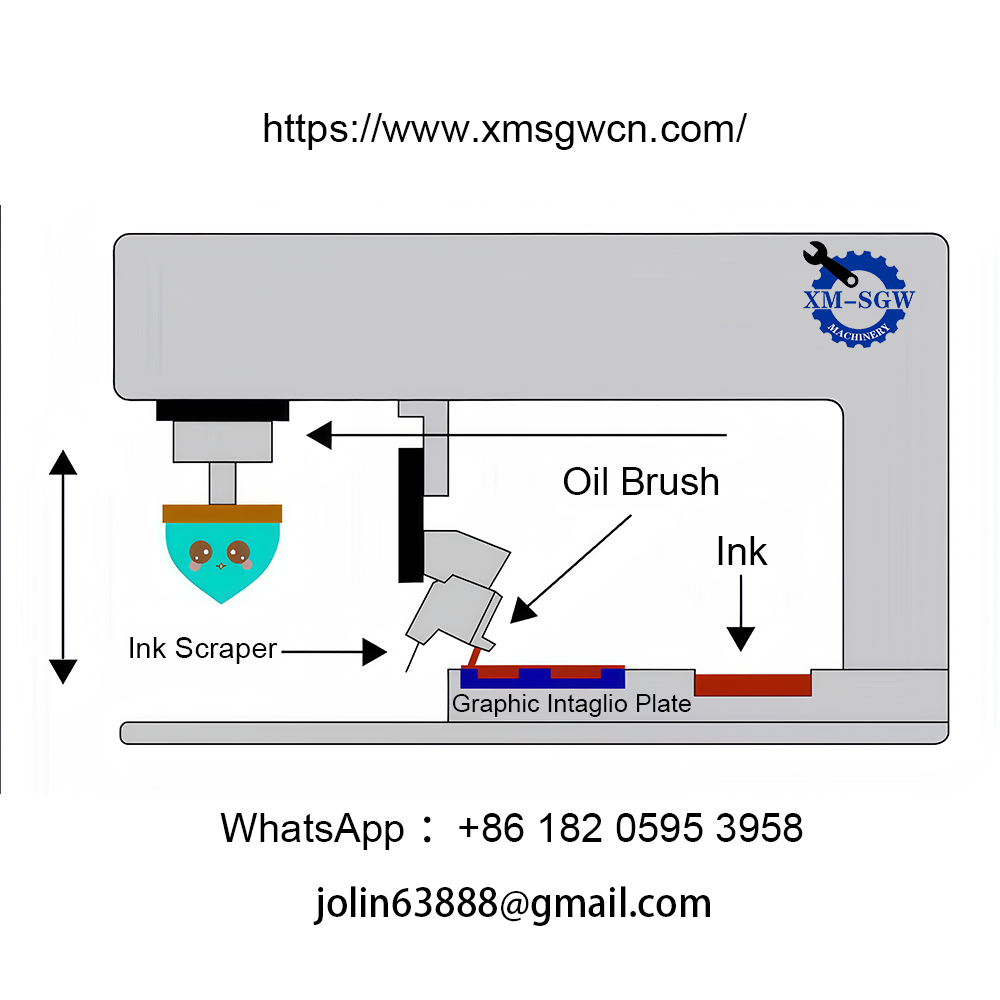

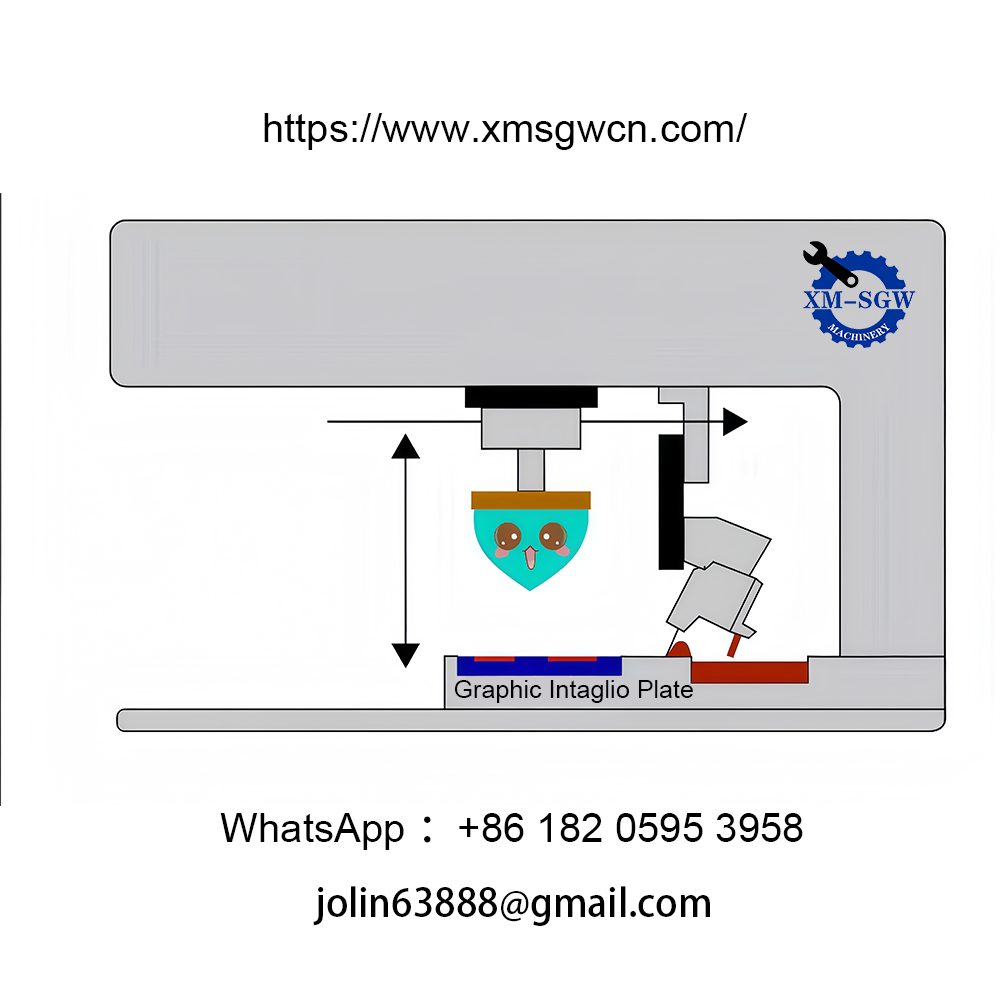

| Cup System | Ink Cup System |

| Ink Dispensing | Automatic Ink Dispensing |

| Print Speed | Adjustable Print Speed |

| Machine features | Multi-Color Registration |

| Drive | Electropneumatic Drive |

Pad Printing Machine Applications

Application Fields of 8-Color Turntable Pad Printers

With 8-color integration and turntable efficiency, it fits multi-color printing needs across industries. Key applications:

- Toy Industry: Print multi-color cartoons on doll faces/mini cars; add colored safety labels to building blocks; mark vivid patterns on plush toy accessories.

- Cosmetics Industry: Decorate lipstick tubes with gradient logos; print colorful patterns on eyeshadow palettes; add brand hues to perfume bottle caps.

- Electronics Industry: Stamp multi-color icons on earphone shells; print colored serial codes on smartwatch dials; mark gradient logos on charger housings.

- Packaging Industry: Add multi-color labels to mini gift boxes; print colored patterns on snack sachets; decorate small cosmetic sample packaging.

- Gift & Craft Industry: Customize multi-color designs on resin pendants; print colored names on leather keychains; add vivid patterns to wooden crafts.

- Stationery Industry: Print multi-color characters on pen barrels; decorate notebook covers with gradient patterns; add colored logos to pencil cases.

- Medical Industry: Mark multi-color warning symbols on syringe plungers; print colored ID codes on reagent bottles; add compliant colored labels to medical device parts.

- Auto Small Parts: Print multi-color buttons on car dashboard components; mark colored logos on sensor housings; decorate small interior trim parts with hues.

- Sports Goods Industry: Add multi-color patterns to fitness tracker bands; print colored logos on mini bike accessories; decorate swimming goggle straps with gradients.

- Pet Supplies Industry: Print multi-color designs on pet chew toys; add colored brand marks to small feeding bowls; decorate pet collar buckles with vivid patterns.

8 Color 360° Rotating Table Pad Printing Machine for toys Video

Get Free Quote of 8 Color 360° Rotating Table Pad Printing Machine

Related Products

Related News

In pad printing—where designs must adhere to curved, textured, or irregular surfaces (from tiny electronic components to large automotive parts)—one […]

In the world of industrial printing, where intricate designs meet irregular surfaces—think curved plastic parts, small metal components, or even […]

In the realm of industrial printing, pad printing machines stand as versatile workhorses, enabling precise image transfer onto surfaces that […]