Hot Selling Large Flat Screen Printing Machine for Plastic Bags Non-woven Bags Shopping Bags

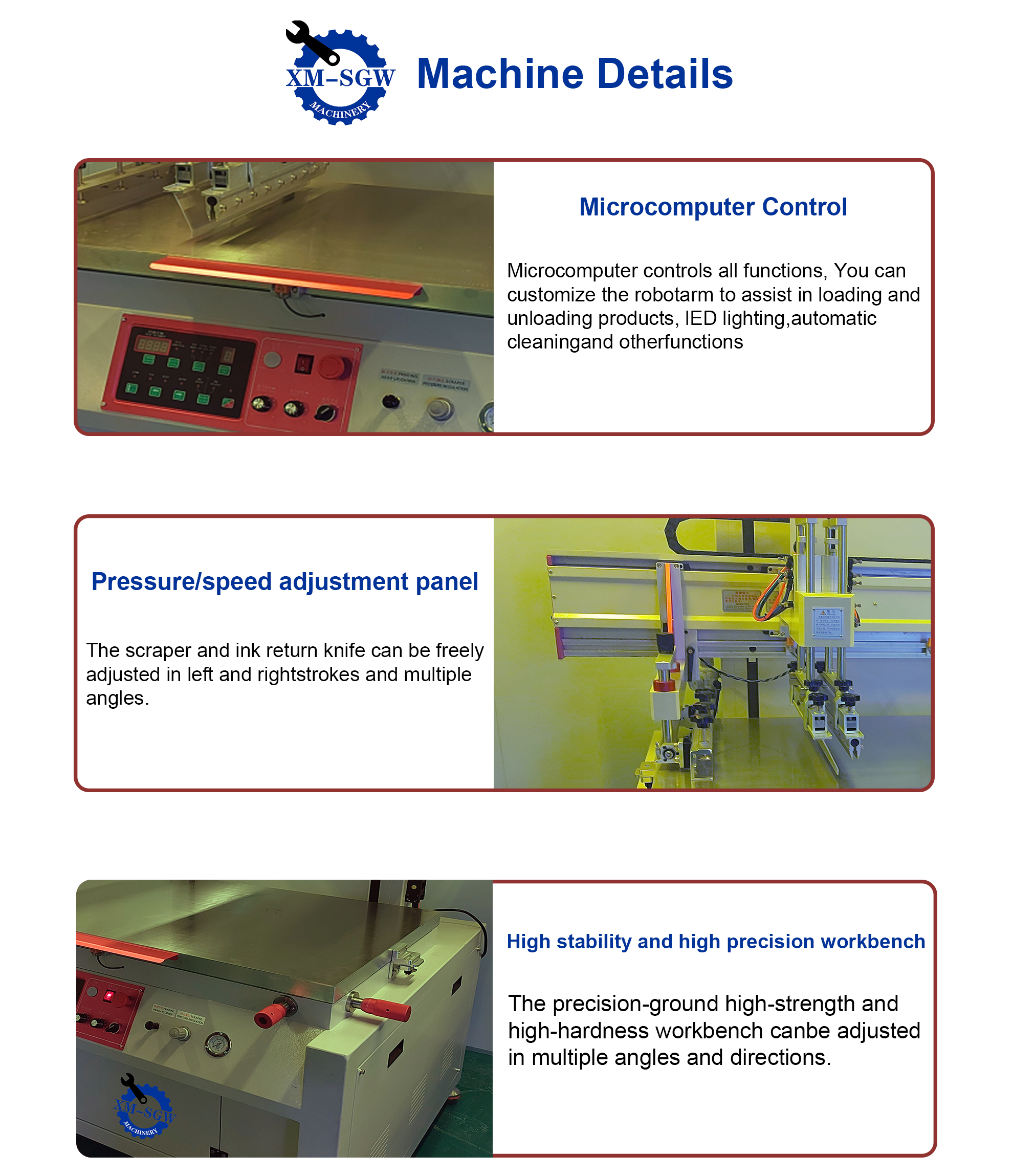

1. Compile action programs using integrated circuits

2. An automatic four-digit counter for counting print quantities; The body is made of all-cast aluminum and the surface is powder-coated and baked.

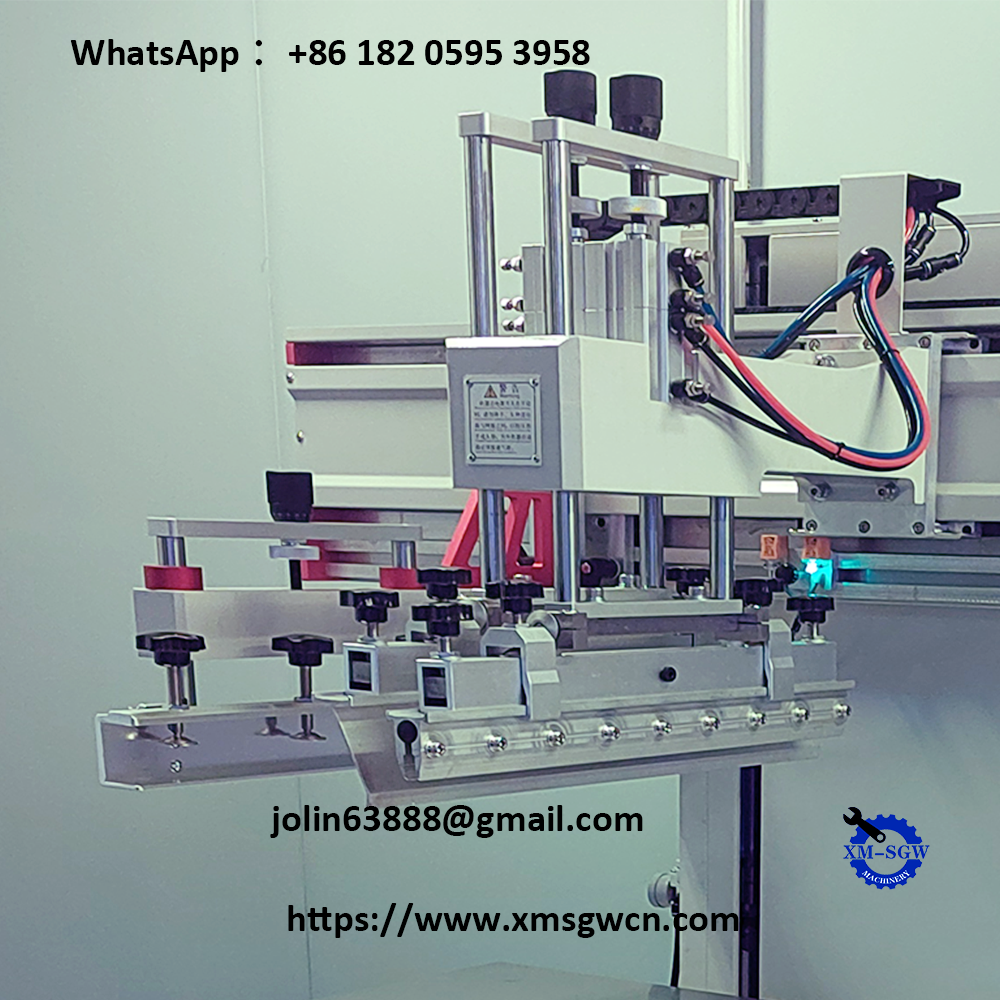

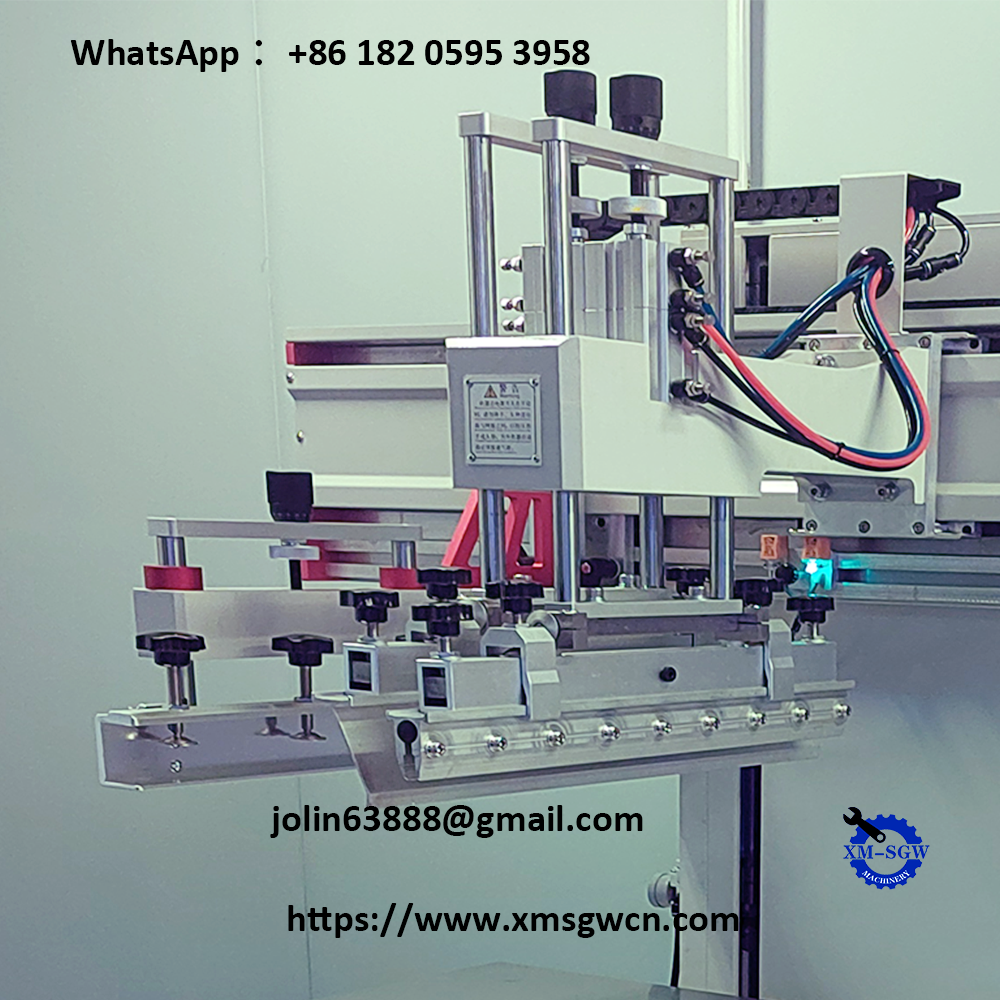

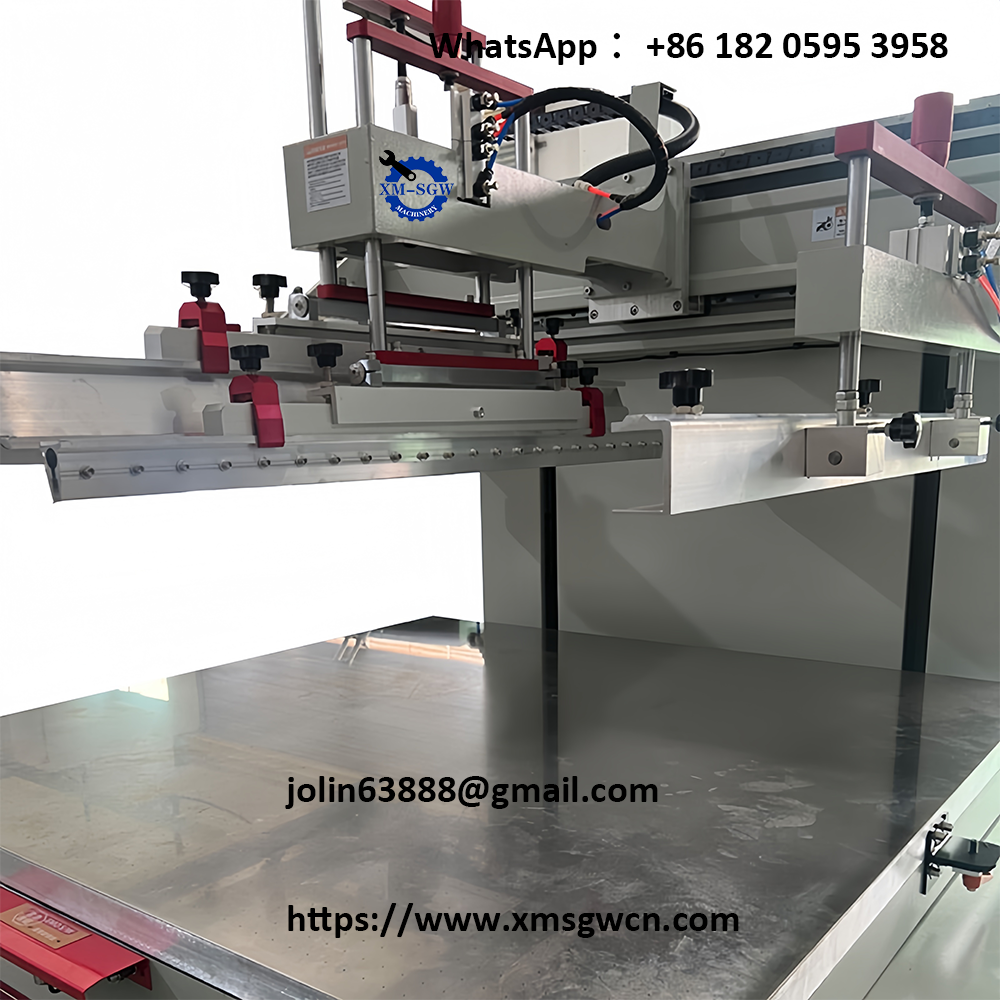

3. The screen lifting adopts a structure driven by a Taiwan motor and linear guide rails, which is stable and highly accurate.

4. The left and right travel is adjustable, and it is limited by Taiwan photoelectric switches.

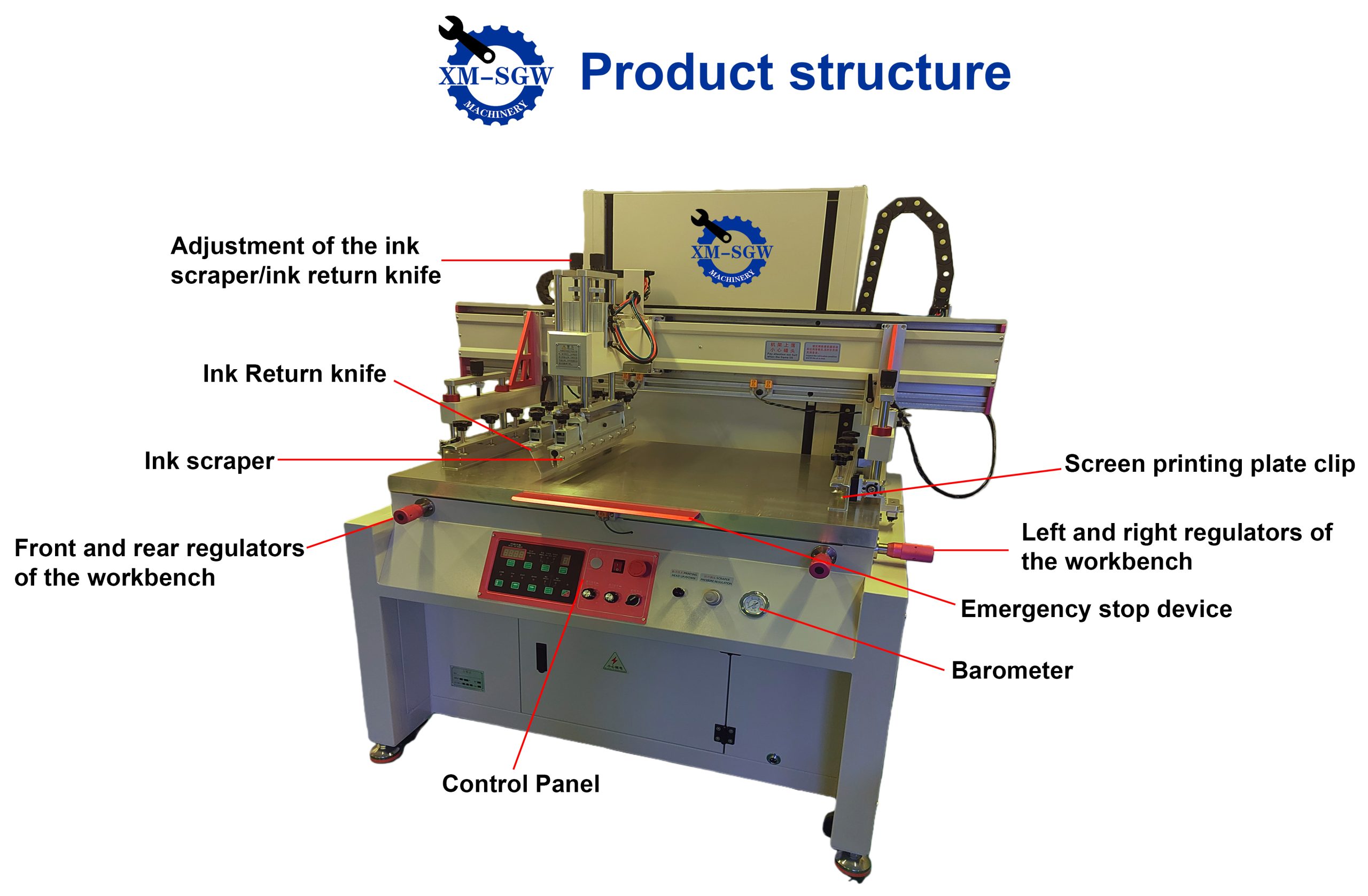

5. The Angle of the scraper/ink return knife can be adjusted freely.

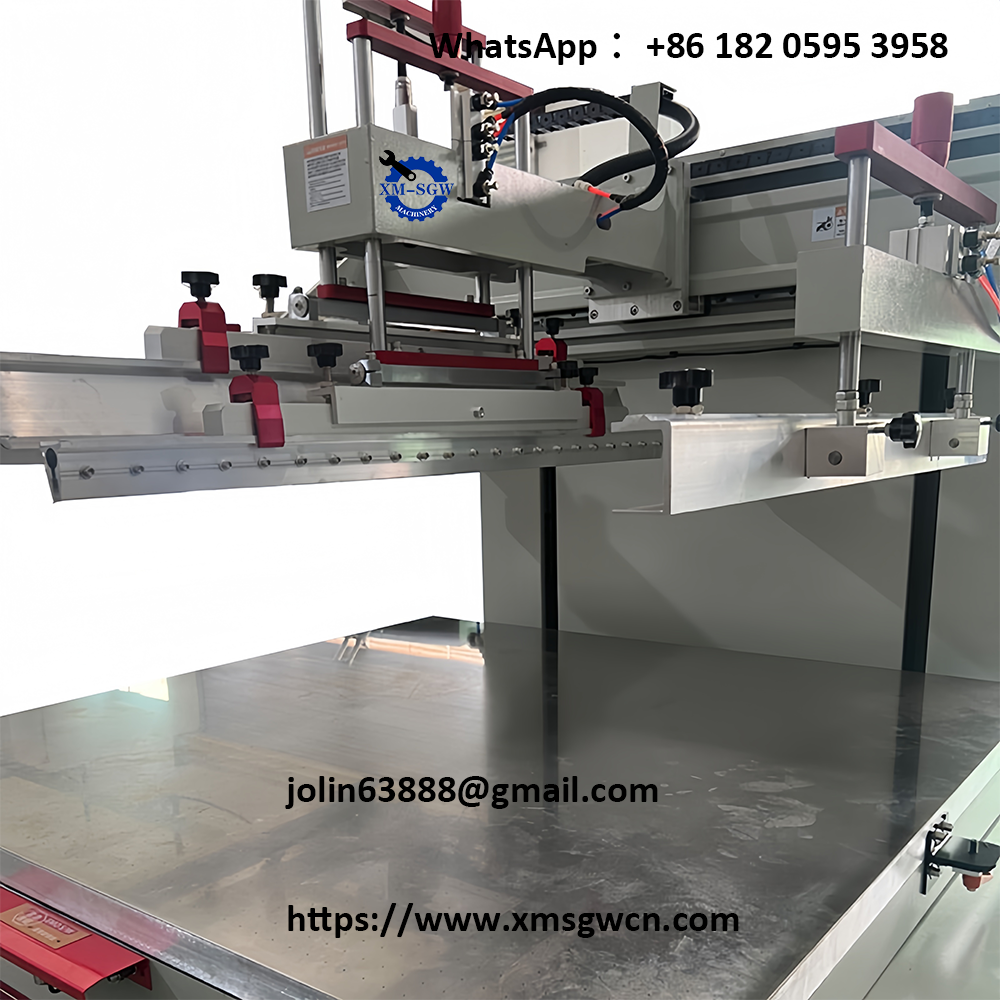

6. Fine-tune the rotation Angle of the workbench to the right front and back, left and right, and then lock it.

7. The position of the mesh frame can be adjusted horizontally up and down.

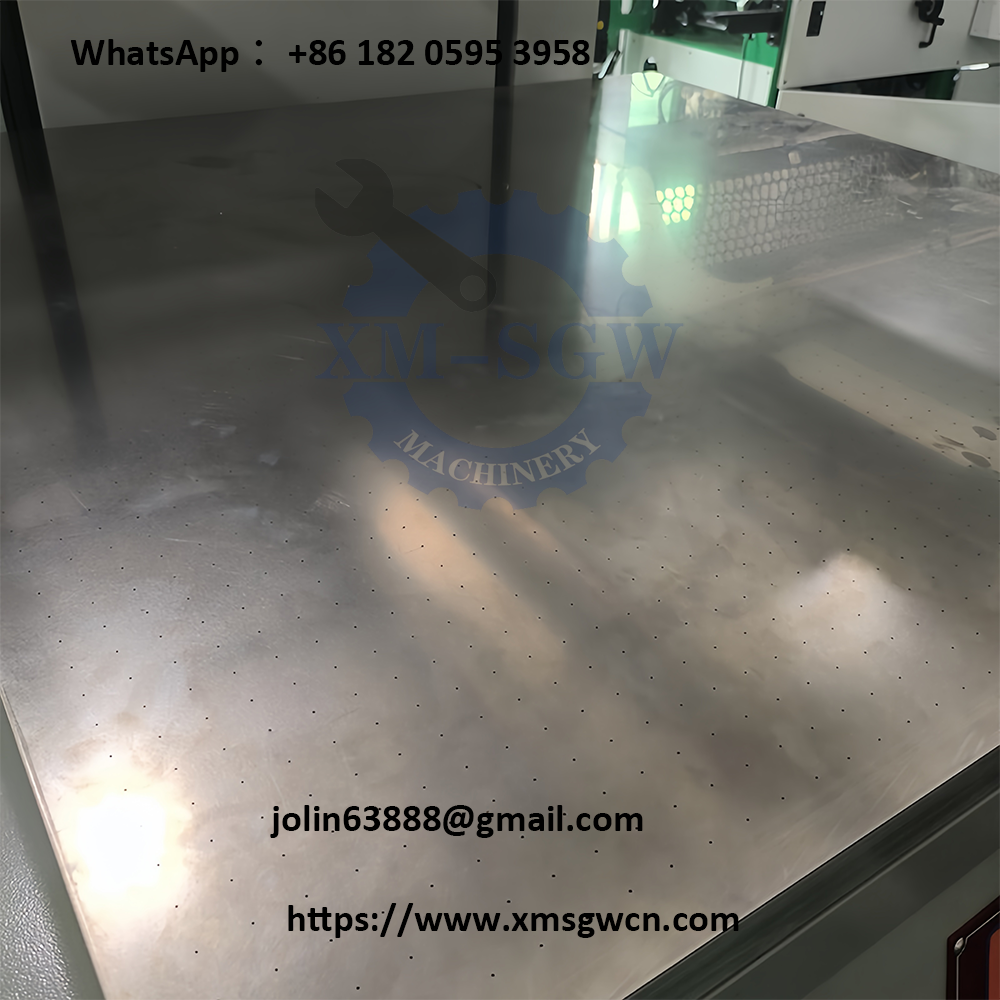

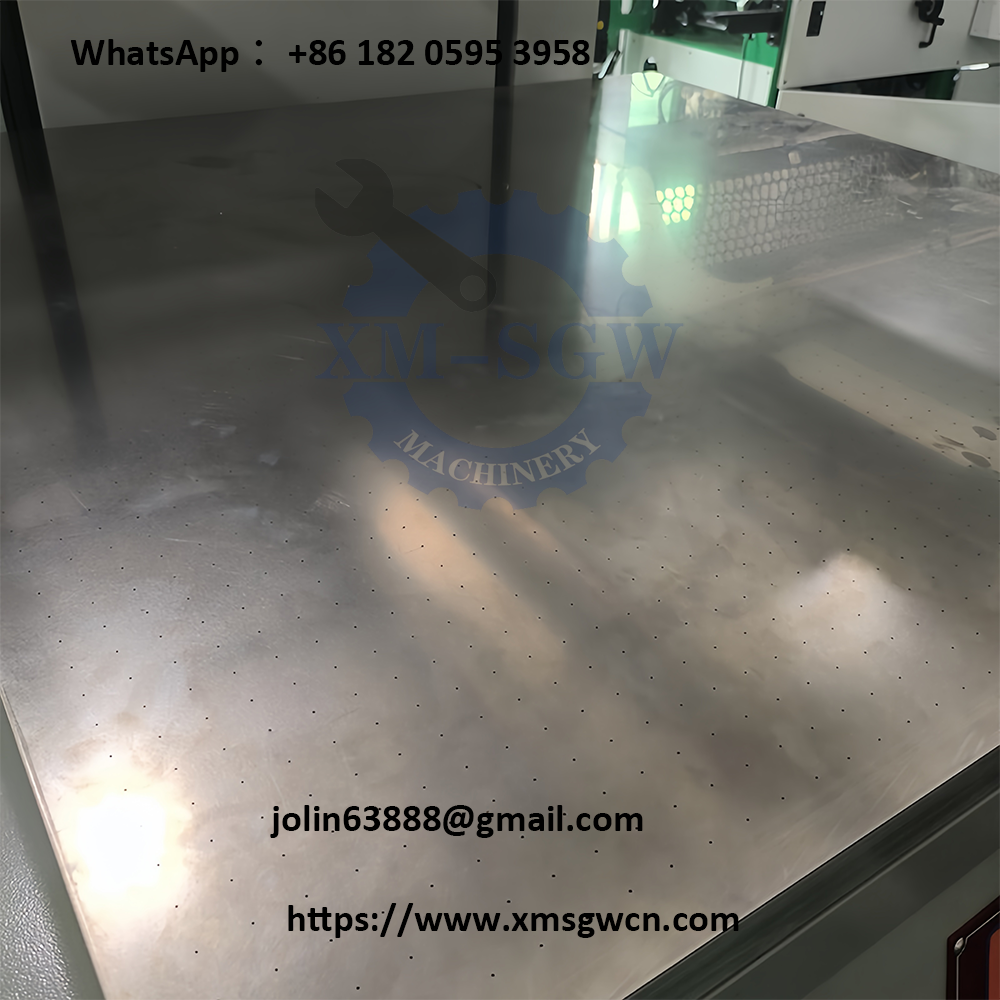

8. Stainless steel suction platform.

Large Flat Screen Printing Machine Description

Large Flat Screen Printing Machine for Plastic Bags Data Sheet

| Key Selling Points | High-accuracy |

| Printing speed | 800pcs/hr |

| Countertop area | 1500*800mm |

| Power | 220V |

| Maximum printing area | 1400*700mm |

| Weight | 400KG |

| Main body size | 1700*1200*1700mm |

| Air pressure | 0.4-0.6MPA |

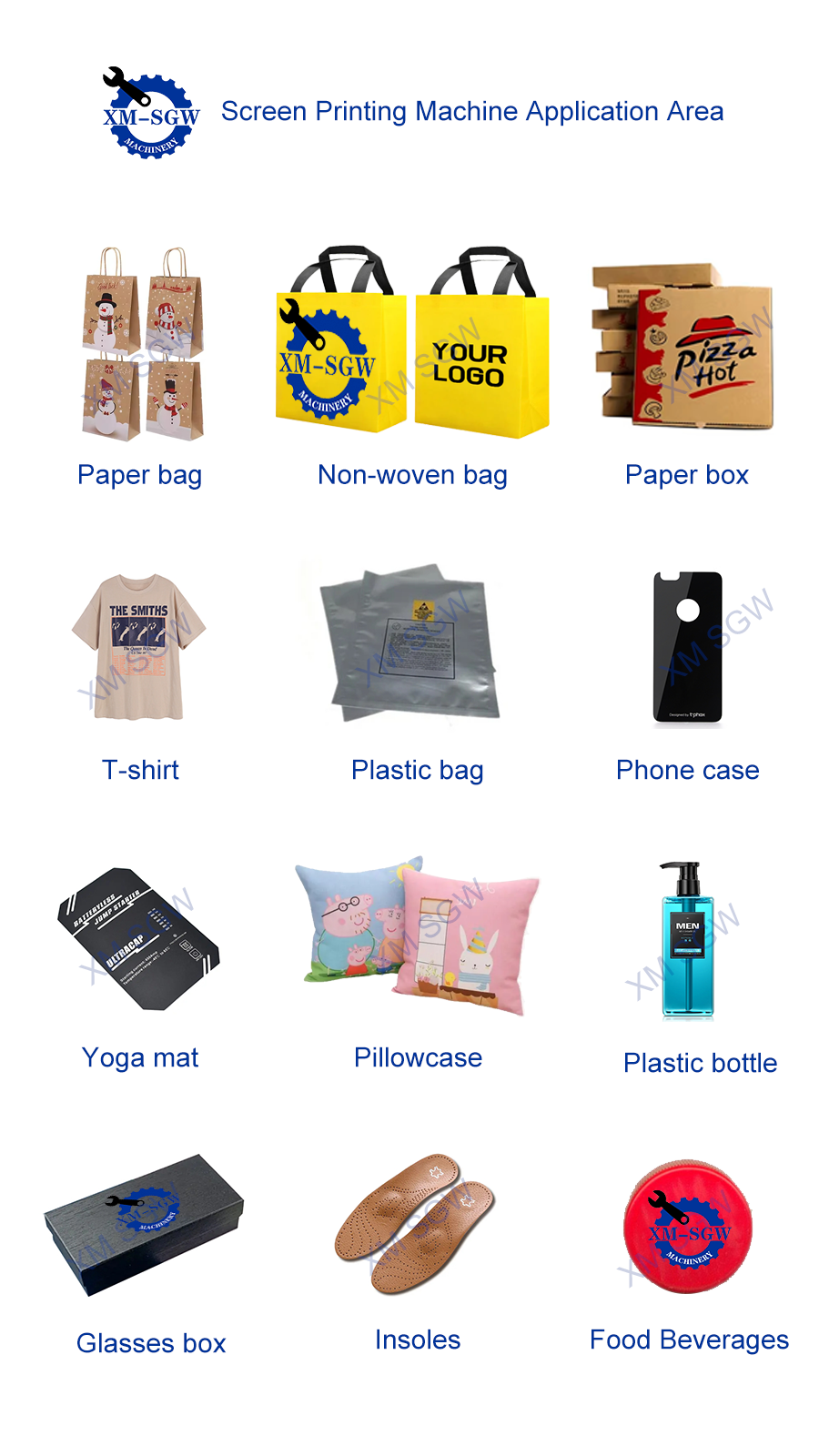

Large Flat Screen Printing Machine Applications

Get Free Quote of Large Flat Screen Printing Machine

Related Products

Related News

In a world where brand visibility matters more than ever, custom-printed bags have become a powerful marketing tool. From retail […]

In the world of screen printing, every detail matters. From ink selection to machine calibration, each element plays […]

Screen printing (also known as silk screening) is a versatile printing technique that brings designs to life on nearly any […]