In the realm of industrial printing, pad printing machines stand as versatile workhorses, enabling precise image transfer onto surfaces that traditional printing methods struggle with. From small electronic components to curved automotive parts, these machines have revolutionized how manufacturers apply logos, text, and graphics.

What is a Pad Printing Machine?

A pad printing machine is a specialized device designed to transfer 2D images onto 3D objects. The process involves four key components working in harmony: a plate (cliché) containing the image, ink, a silicone pad, and the substrate (object being printed).

The magic lies in the flexibility of the silicone pad, which conforms to irregular surfaces while maintaining image integrity. This unique capability makes pad printing indispensable across numerous industries.

How Does Pad Printing Work?

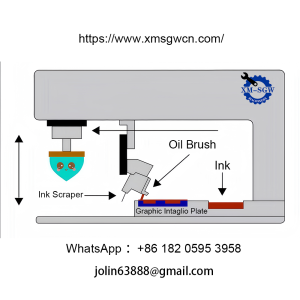

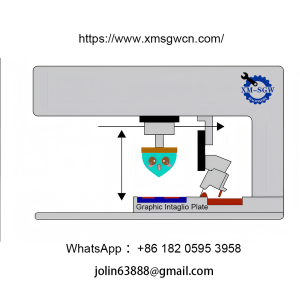

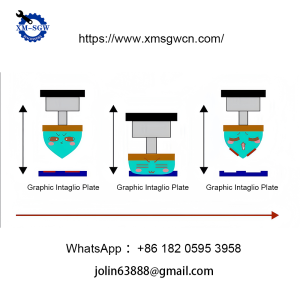

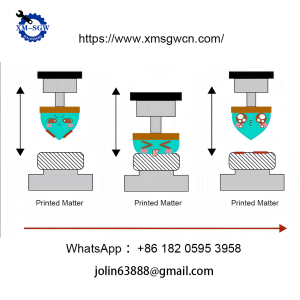

The pad printing process follows a precise sequence:

- Inking: The cliché (usually made of steel or photopolymer) is flooded with ink

- Doctoring: A blade removes excess ink, leaving ink only in the etched image area

- Pickup: The silicone pad presses against the cliché, picking up the inked image

- Transfer: The pad moves to the substrate and deposits the image with consistent pressure

- This process can be completed in fractions of a second, making high-volume production feasible.

Types of Pad Printing Machines

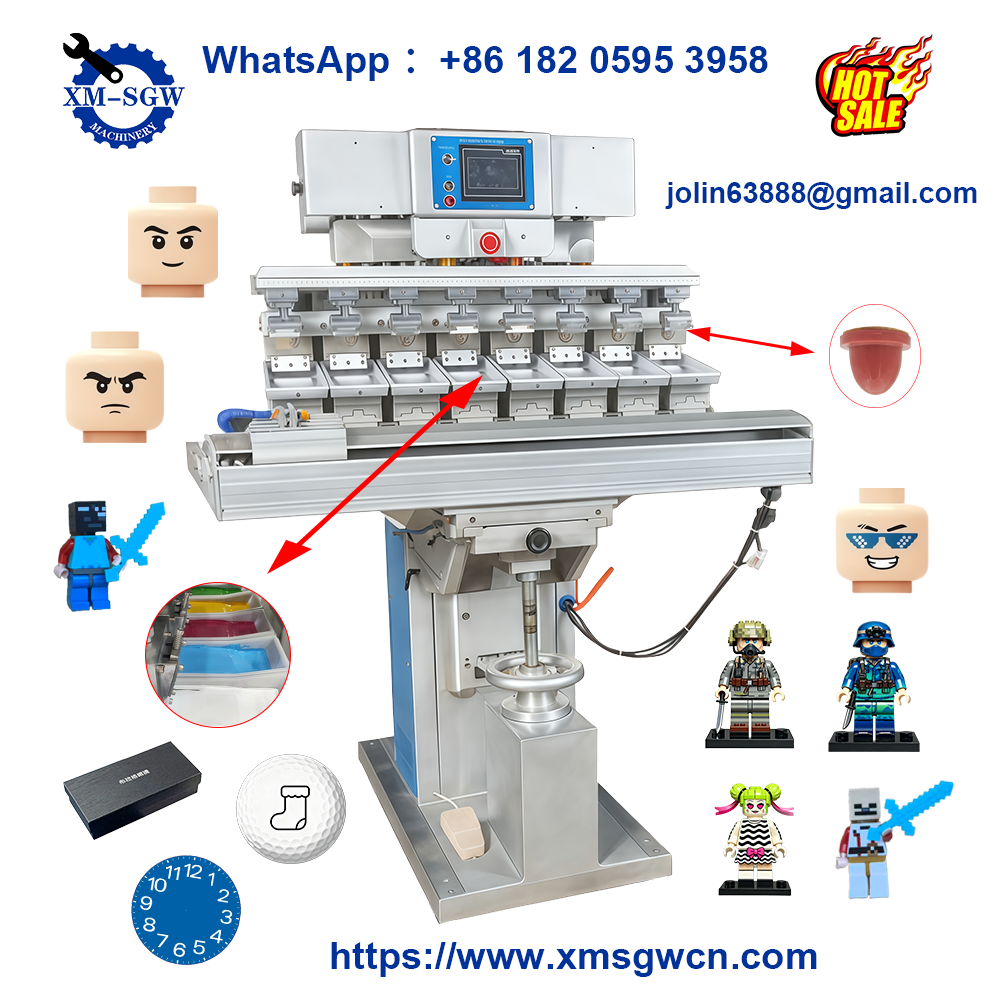

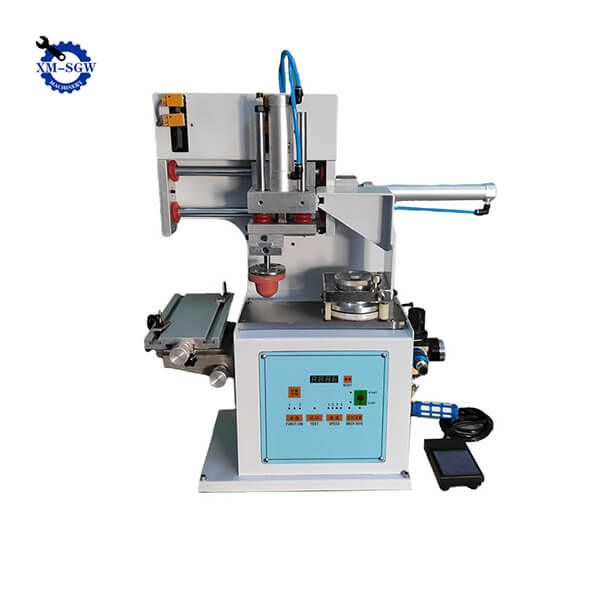

Pad printing equipment ranges from simple manual devices to sophisticated automated systems:

- Manual machines: Ideal for small batches and prototyping, requiring operator involvement at each step

- Semi-automatic machines: Automate the printing cycle while requiring manual loading/unloading

- Automatic machines: Feature conveyor systems and robotic loading for uninterrupted production

- Multi-color machines: Enable complex designs with registration accuracy as tight as 0.01mm

Applications Across Industries

The versatility of pad printing machines makes them invaluable:

- Electronics: Printing on circuit boards, connectors, and mobile device components

- Automotive: Applying labels to dashboards, buttons, and under-hood parts

- Medical: Marking surgical instruments and medical devices with permanent identifiers

- Promotional items: Customizing pens, keychains, and drinkware

- Aerospace: Creating durable markings on various aircraft components

Advantages of Pad Printing

Compared to other decorating methods, pad printing offers distinct benefits:

- Ability to print on curved, concave, convex, and irregular surfaces

- Precise image reproduction even for tiny details (down to 0.1mm line width)

- Quick changeover between jobs with minimal setup time

- Compatibility with diverse materials: plastics, metals, glass, ceramics, and more

- Cost-effective for both short runs and mass production

Choosing the Right Pad Printing Machine

Selecting appropriate equipment requires considering:

- Production volume requirements

- Substrate size, shape, and material

- Required resolution and image complexity

- Color requirements (single vs. multi-color)

- Available floor space and budget

Maintenance and Troubleshooting

Proper maintenance ensures consistent results and extends machine life:

- Regular cleaning of clichés and pads

- Ink system maintenance to prevent drying and clogging

- Calibration checks for registration accuracy

- Replacement of worn components (blades, pads, etc.)

- Common issues like uneven printing or poor adhesion can usually be resolved by adjusting ink viscosity, pad hardness, or pressure settings.

The Future of Pad Printing

Advancements in pad printing technology continue to expand possibilities, with improved automation, better ink formulations for sustainability, and integration with digital design workflows. As manufacturing becomes more customized, the flexibility of pad printing ensures its continued relevance in the industrial landscape.

Whether you’re a small business entering the custom printing market or a large manufacturer looking to enhance product decoration, understanding pad printing technology can open new avenues for product enhancement and brand differentiation.