In pad printing—where designs must adhere to curved, textured, or irregular surfaces (from tiny electronic components to large automotive parts)—one component stands between your etched steel plate and a perfect print: the pad printing silicone head. Often called the “heart of transfer,” this flexible tool turns rigid design recesses into precise, conformable prints. Unlike rigid printing parts, it bends, adapts, and delivers ink with consistency—making it irreplaceable for complex printing tasks.

Let’s break down what pad printing silicone heads are, how they work, and how to choose, maintain, and troubleshoot them for long-lasting, high-quality results.

What Is a Pad Printing Silicone Head?

A pad printing silicone head (or “transfer pad”) is a moldable, high-elasticity tool made from premium silicone rubber. Its primary job? Pick up ink from the etched recesses of a pad printing steel plate and transfer it evenly onto the target substrate—whether that substrate is plastic, metal, glass, or ceramic.

Key characteristics that set it apart:

- Flexibility: Conforms to surfaces with angles, curves, or small crevices (e.g., a toy’s rounded edges or a phone’s button indentations).

- Resilience: Returns to its original shape after each print, preventing deformation and ensuring consistent ink transfer.

- Ink Compatibility: Resists swelling or breaking down when exposed to industrial printing solvents (a must for long production runs).

How Does a Pad Printing Silicone Head Work?

The magic lies in its ability to bridge the gap between the flat steel plate and 3D substrates. Here’s the step-by-step process (paired with your pad printing steel plate):

- Ink Preparation: The steel plate’s etched design is filled with ink, and excess ink is wiped away by a doctor blade.

- Ink Pickup: The silicone head descends onto the steel plate. Its soft, porous surface sucks up ink from the etched recesses—thanks to surface tension and the silicone’s micro-texture.

- Conformation: The head lifts and moves to the substrate. As it presses down, it stretches and molds to the substrate’s shape (e.g., wrapping around a cylindrical pen or fitting into a shallow groove).

- Ink Transfer: The silicone’s elasticity releases the ink onto the substrate as it pulls away. The result? A crisp, aligned print—even on surfaces that traditional flat printing can’t reach.

Without a well-designed silicone head, this process fails: ink smudges, incomplete transfers, or uneven coverage become inevitable.

Key Properties to Look for in a Quality Silicone Head

Not all silicone heads are equal. The best ones are engineered for your specific project needs. Focus on these four critical traits:

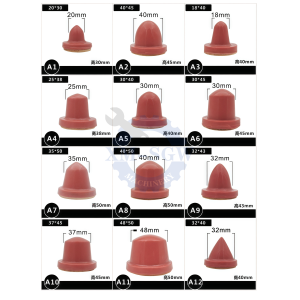

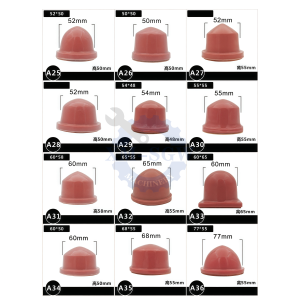

1. Hardness (Shore A Durometer)

Hardness determines how well the head adapts to substrates and holds ink. Measured on the Shore A scale (common range: 20A–80A):

- Soft Heads (20A–40A): Ideal for irregular, textured, or deep-cavity surfaces (e.g., rubber grips, molded plastic parts). They conform deeply but may require more frequent replacement (prone to tearing).

- Medium Heads (50A–60A): The “all-purpose” choice. Works for slightly curved or flat surfaces (e.g., electronics casings, promotional mugs) and balances flexibility with durability.

- Hard Heads (70A–80A): Best for flat, smooth substrates (e.g., metal nameplates, glass jars). They hold shape well for high-volume runs but won’t conform to tight curves.

2. Elasticity & Recovery

High elasticity ensures the head bounces back to its original form after each print. Poor recovery leads to:

- Deformed ink patterns (e.g., stretched logos).

- Uneven pressure on subsequent prints.

Look for silicone heads made with “high-rebound” formulas—they last 2–3x longer than low-quality alternatives.

3. Solvent Resistance

Ink solvents (e.g., alcohol, ketones) can degrade low-grade silicone over time, causing swelling, cracking, or ink bleeding. Choose heads labeled “solvent-resistant” (often made with vinyl-methyl silicone) if you use aggressive inks (e.g., for industrial metal parts).

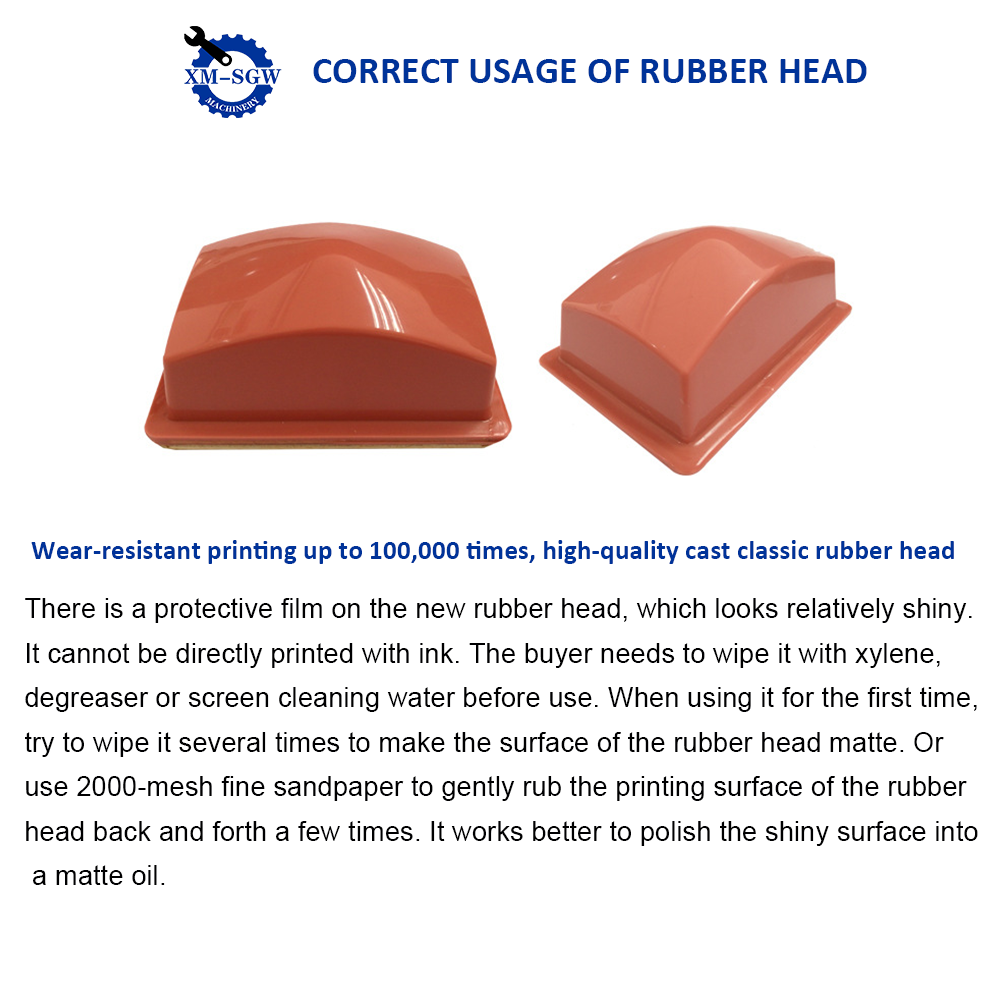

4. Surface Smoothness

A smooth silicone surface ensures even ink transfer—no streaks or missing spots. Avoid heads with visible defects (e.g., bubbles, scratches) as these will replicate in your prints.

How to Choose the Right Silicone Head for Your Project

Follow this 4-step checklist to match the head to your needs:

- Analyze Your Substrate:

- Curved/textured → Soft head (20A–40A).

- Flat/smooth → Hard head (70A–80A).

- Mixed surfaces → Medium head (50A–60A).

- Consider Ink Type:

- Solvent-based inks → Solvent-resistant silicone.

- Water-based inks → Standard silicone (cost-effective, no solvent risk).

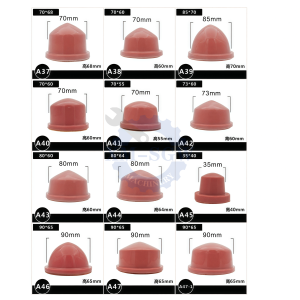

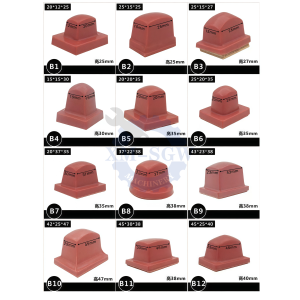

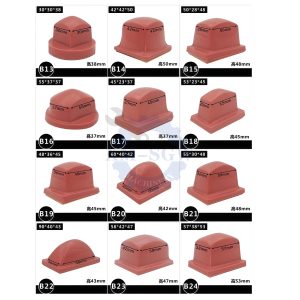

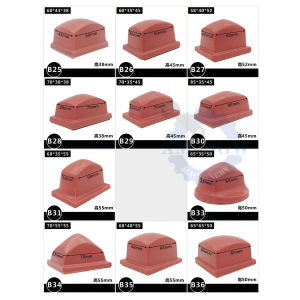

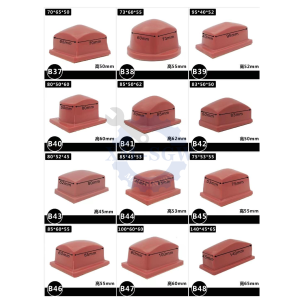

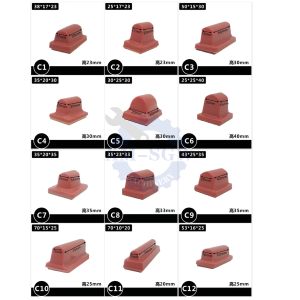

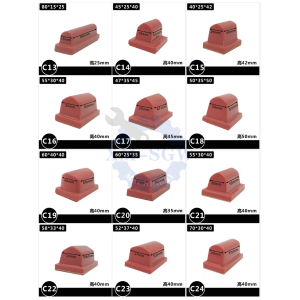

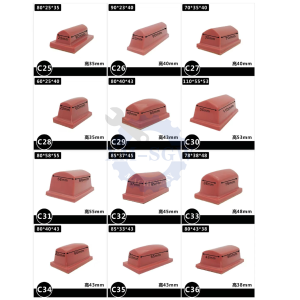

- Match Size to Your Design:

The head should be 10–20% larger than your design. A too-small head will miss edges; a too-large one wastes ink and may hit nearby substrate features.

- Opt for Customization (When Needed):

For unique substrates (e.g., deep-dish parts, irregularly shaped tools), custom-molded silicone heads are worth the investment. They ensure full contact with the substrate and eliminate transfer gaps.

Maintenance Tips to Extend Silicone Head Lifespan

A well-cared-for silicone head can last 10,000–50,000 prints (depending on hardness and use). Follow these rules:

- Clean Gently After Use: Wipe away ink residue with a soft, lint-free cloth and mild solvent (avoid acetone or abrasive cleaners—they break down silicone).

- Store Properly: Keep heads in a cool, dry place, away from direct sunlight and sharp objects. Use a dedicated storage case to prevent deformation.

- Inspect Before Each Run: Check for:

- Surface cracks or tears (replace immediately—they cause ink leaks).

- Swelling (sign of solvent incompatibility—switch to a resistant head).

- Permanent deformation (e.g., a “dent” from over-pressing—replace to avoid uneven prints).

- Avoid Over-Pressing: Too much pressure stretches the silicone prematurely. Adjust your machine’s pressure settings to the minimum needed for full ink transfer.

Common FAQs About Pad Printing Silicone Heads

Q: Why is my silicone head leaving blurry prints?

A: Likely causes:

- Hardness mismatch (e.g., a hard head on a curved surface).

- Surface damage (scratches or swelling).

- Overused ink (clean the head and plate thoroughly).

Q: Can I reuse a silicone head after it tears?

A: No—even small tears will worsen and cause inconsistent ink transfer. Replace torn heads immediately to avoid ruining substrates.

Q: How often should I replace a silicone head?

A: It depends on use:

- Soft heads (20A–40A): Every 10,000–20,000 prints.

- Medium/hard heads (50A–80A): Every 30,000–50,000 prints.

- If you notice a drop in print quality (smudges, gaps), replace it sooner.

Final Thought: Invest in Quality for Consistent Results

A pad printing silicone head isn’t just a “consumable”—it’s a critical part of your print quality. Choosing the right hardness, size, and material ensures your designs look professional, even on the most challenging surfaces. And with proper maintenance, you’ll cut down on replacement costs and production delays.

Ready to find the perfect silicone head for your project? Our team specializes in custom and standard pad printing silicone heads—tailored to your substrate, ink, and volume needs. Contact us today for a free consultation, and let’s make your prints flawless.

Got questions about silicone head hardness or customization? Drop us a line—our experts are here to help!